Miniature hydro-power generation system

A technology for generators and shells, applied in the field of hydroelectric power generation, which can solve the problems of high cost, difficulty, and time-consuming installation of switchboards and/or cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Exemplary embodiments of the present invention are described below with reference to specific structures, and it will be understood by those skilled in the art that various changes and modifications can be made to these specific structures without departing from the scope of the claims. The presently preferred embodiments can be used with any water treatment system that requires power and includes water flow; however, these embodiments are designed for residential or mobile use. Those skilled in the art will also understand that these embodiments may be used with fluids other than water and the use of the terms "water" and "hydro" should not be considered a limitation.

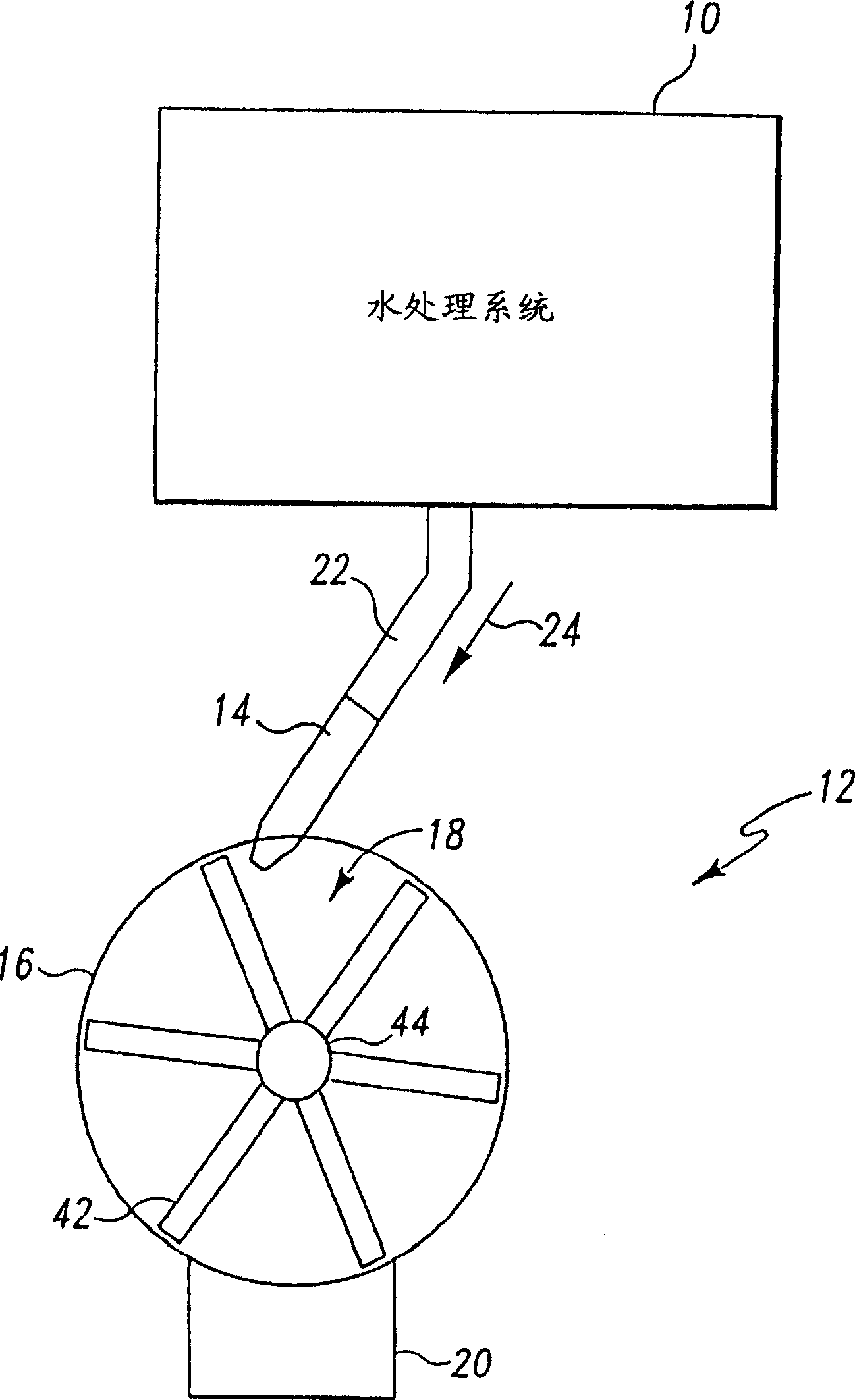

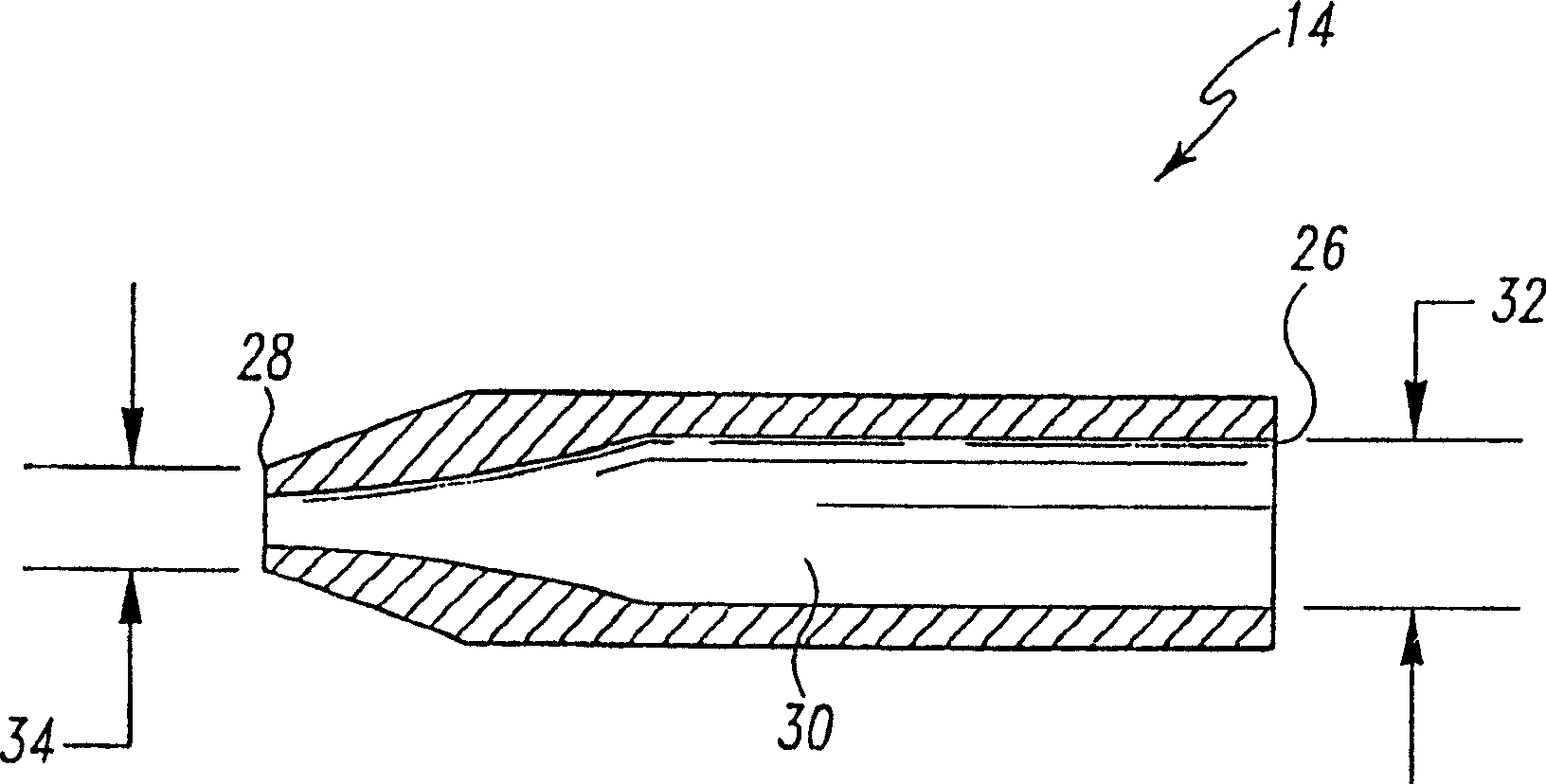

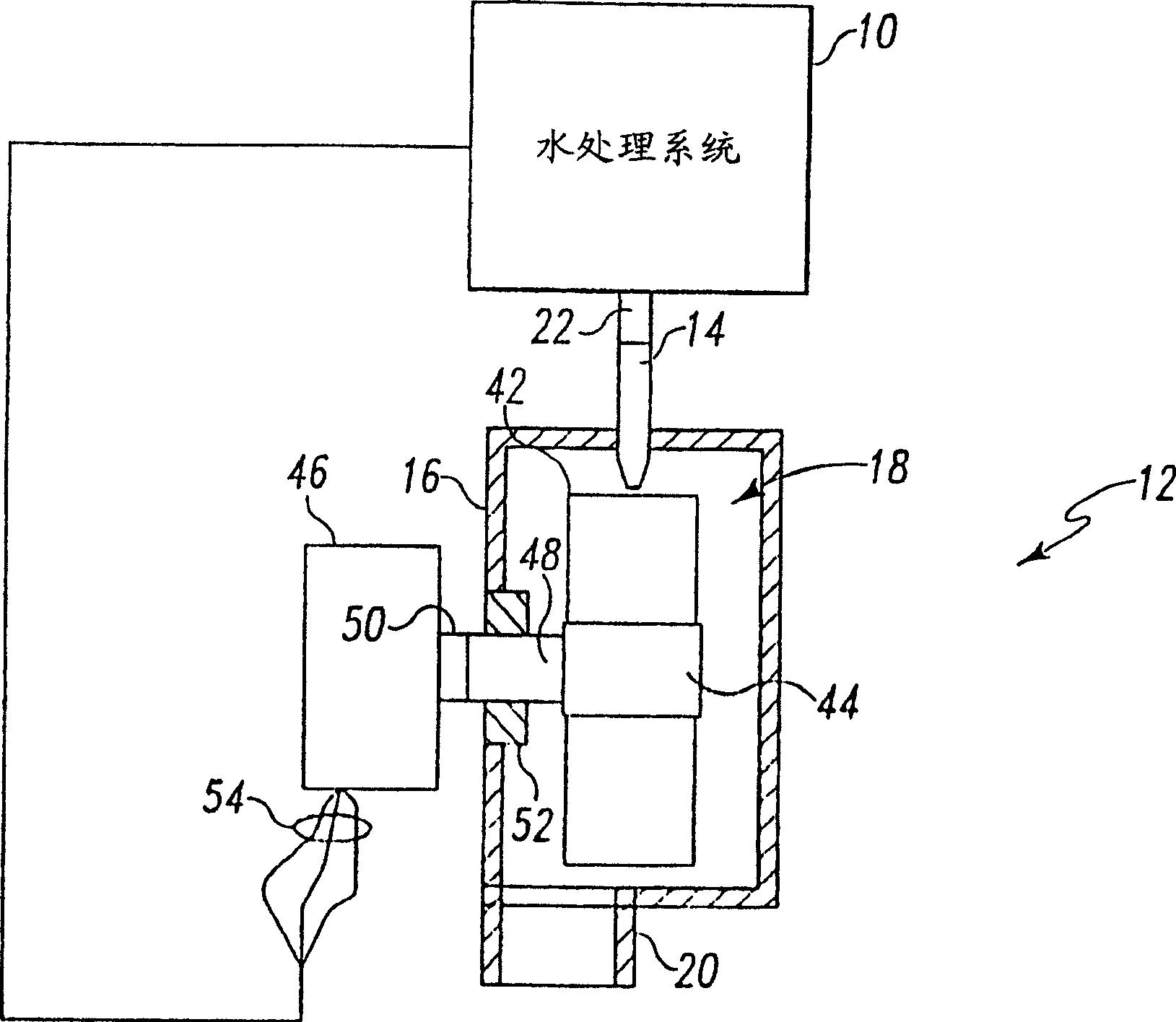

[0046] figure 1 Is a side view of a water treatment system 10 connected to a preferred hydroelectric power generation system 12 . In this embodiment, a hydroelectric power generation system 12 includes a nozzle 14 , a casing 16 , an impeller 18 and a casing outlet 20 . The nozzle 14 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com