Apparatus for separating dust from vacuum cleaner

A dust separation and vacuum cleaner technology, applied in suction filters, swirl devices, etc., can solve the problems of large airflow loss, high motor power, and high use cost, and achieve the effect of improving vacuum degree and facilitating modeling and design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

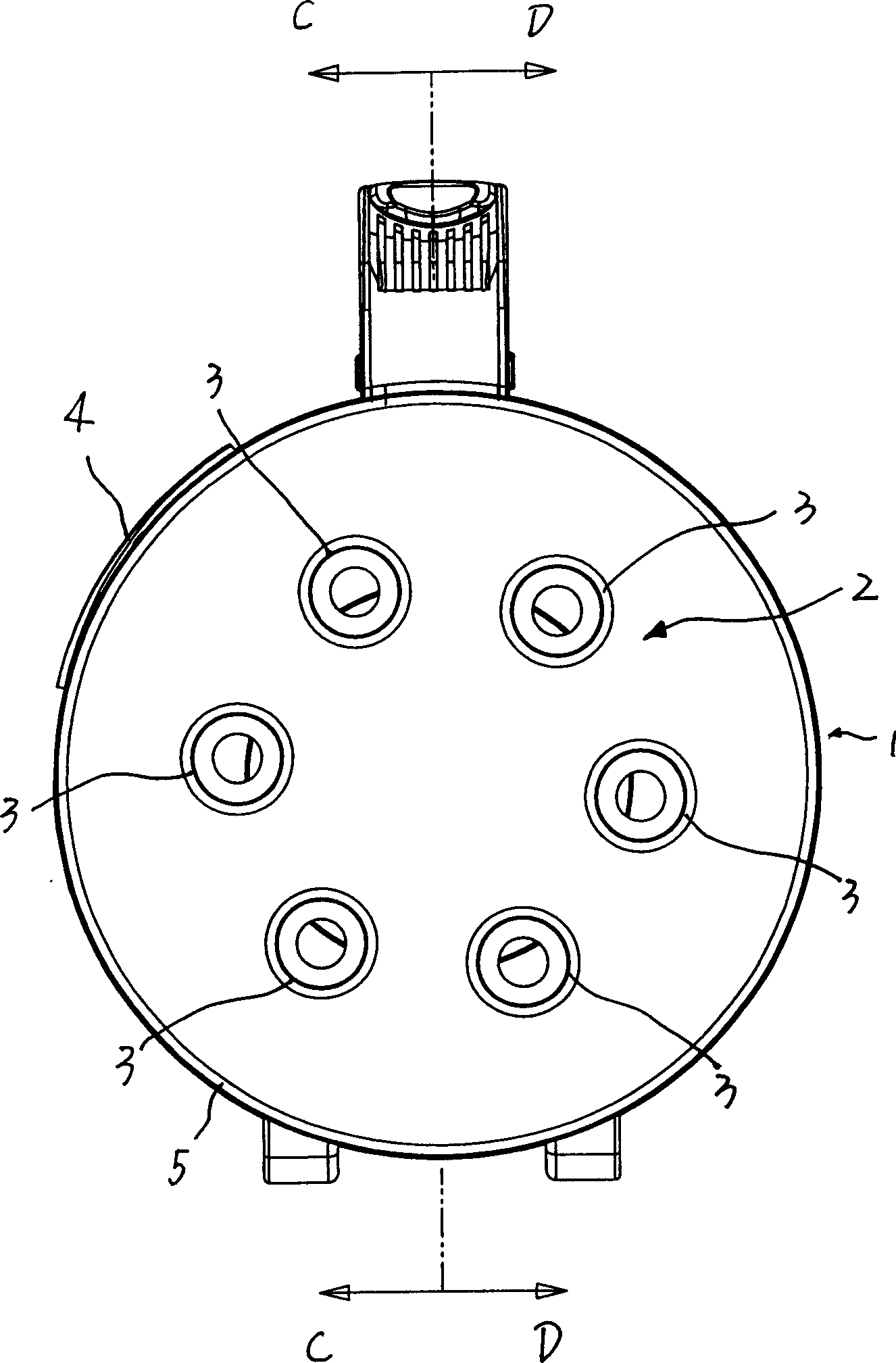

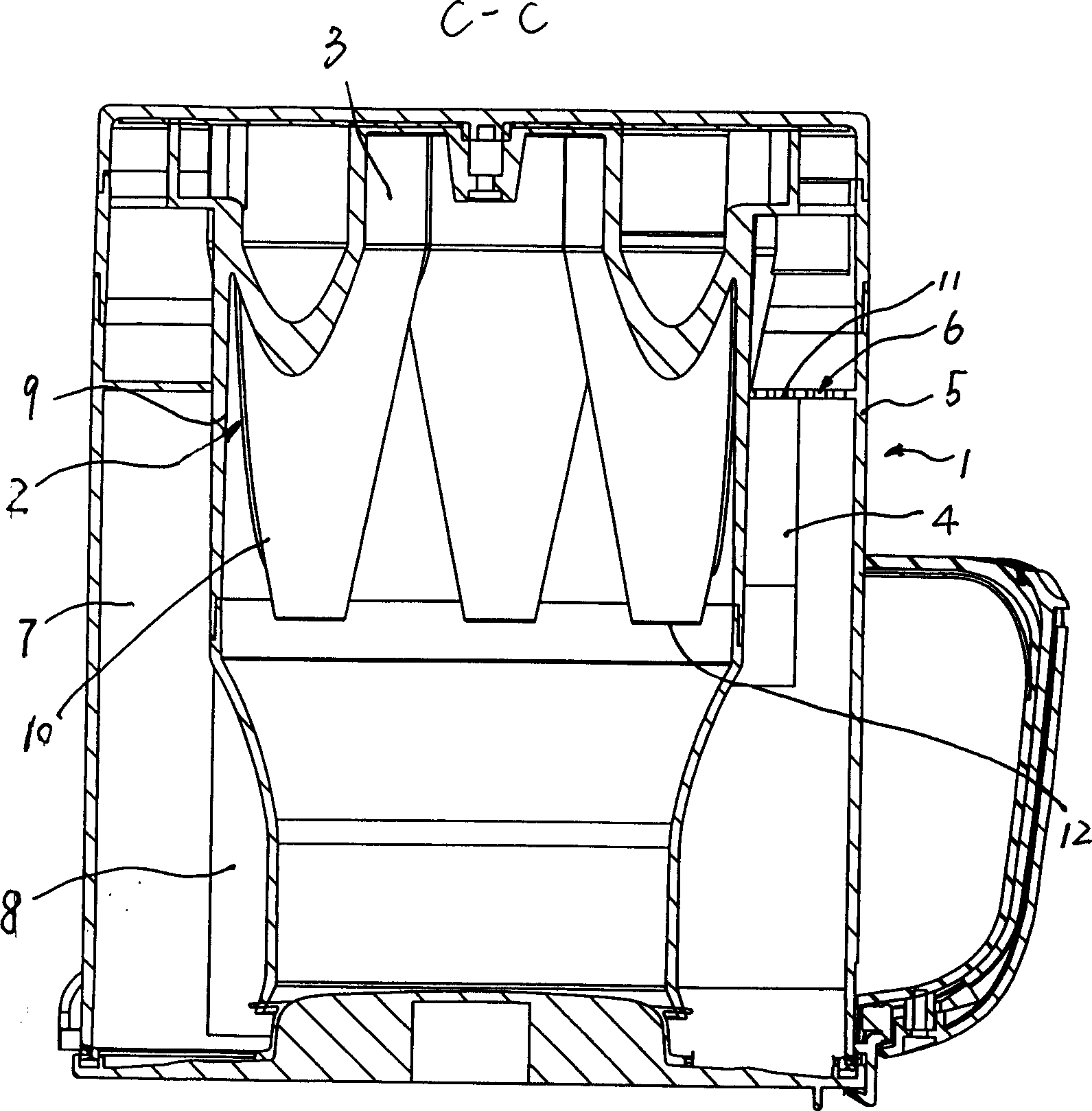

[0013] See attached figure 1 - attached Figure 6 , a dust separation device on a vacuum cleaner, comprising an upstream separator 1 located upstream and a downstream separator 2 located downstream, the upstream separator 1 is an inertial separator, and the downstream separator 2 is a cyclone separator , said downstream separator 2 at least partly protrudes into said upstream separator 1 . After the upstream separator 1 separates the large particles of dust, the airflow enters the downstream separator 2 to separate the small particles of dust.

[0014] The downstream separator 2 includes a plurality of cyclone separators 3 arranged side by side, and each cyclone separator 3 at least partially extends into the upstream separator 1 .

[0015] The upstream separator 1 has an air flow channel 7, as an inertial separator, the air flow channel 7 is provided with an air flow baffle 8 along its cross-sectional direction, so that the large particles of dust in the air flow collide wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com