Bringing along automatic cleanout inside pipe by teeth at rotational flow mouth, and technique for strengthening heat transfer

A technology of automatic cleaning and heat transfer enhancement, which is applied in the direction of cleaning heat transfer devices, heat transfer modification, non-rotating equipment cleaning, etc., can solve problems such as expensive manufacturing costs, complex structures, and loss of engineering value, and achieve reliable automatic cleaning, The effect of accelerating the rotation speed and solving the difficulty of starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

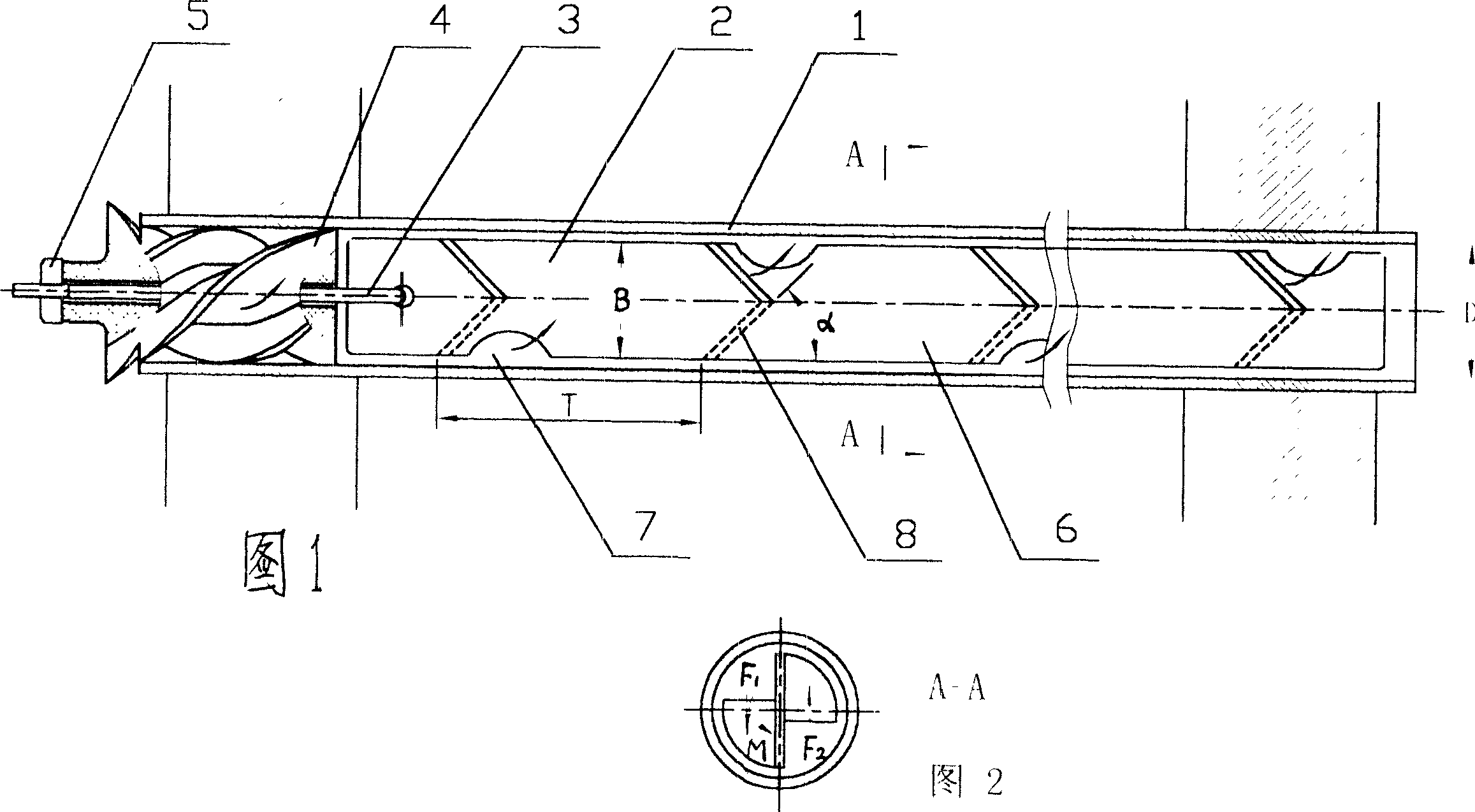

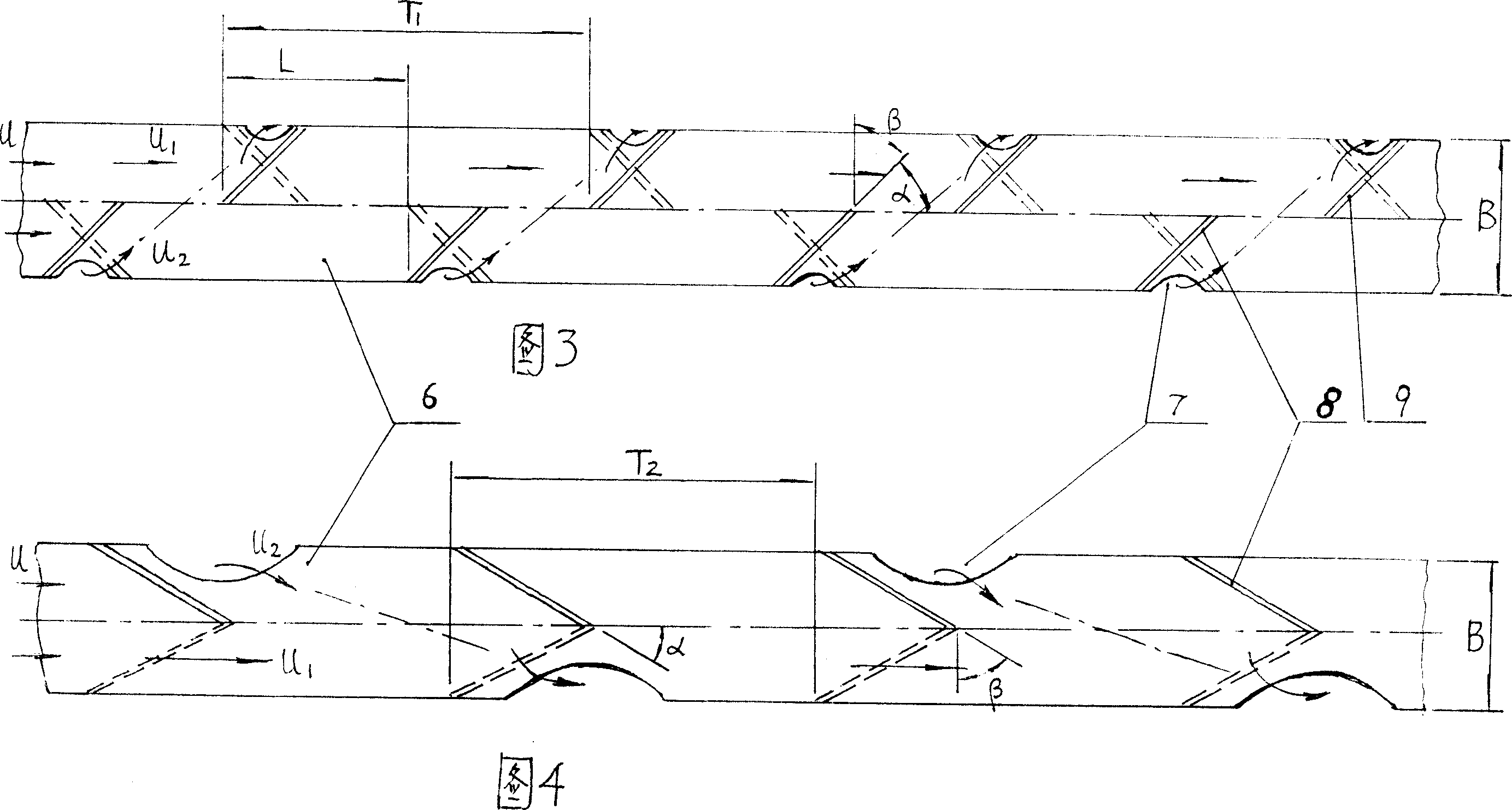

[0011] The present invention will be further described in detail below in conjunction with accompanying drawings 1 , 2 , 3 and 4 .

[0012] In the figure 1. Heat transfer tube 2. Swirl tooth straight belt 3. Rotating shaft 4. Swirl bearing 5. Sliding bearing 6. Straight belt

[0013] 7. Swirl mouth 8. Power teeth 9. Auxiliary teeth

[0014] The automatic cleaning and heat transfer enhancement technology in the swirling straight belt tube is composed of a heat transfer tube 1, a swirling straight belt 2 and a rotating shaft 3. The swirl mouth-toothed straight belt 2 is made of the straight belt 6 with the swirl mouth 7 and the power teeth 8, and can also be made of the straight belt 6 with the swirl mouth 7, the power teeth 8 and the auxiliary teeth 9. The width B of the straight belt 6 is slightly smaller than the inner diameter D of the heat transfer tube 1, and the width ratio B / D is in the range of 0.70-0.95. The power teeth 8 and auxiliary teeth 9 are evenly arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com