Oxygen compressor preheating device and method

A compressor and preheating technology, which is applied in the direction of mechanical equipment, machines/engines, liquid variable displacement machinery, etc., can solve the problem of damage to the core parts of the compressor, the cylinder cup, the increase in the loss of the compressor cylinder and the cup, and the impact on the system. Oxygen machine service life and other issues, to avoid start-up difficulties, prolong service life, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

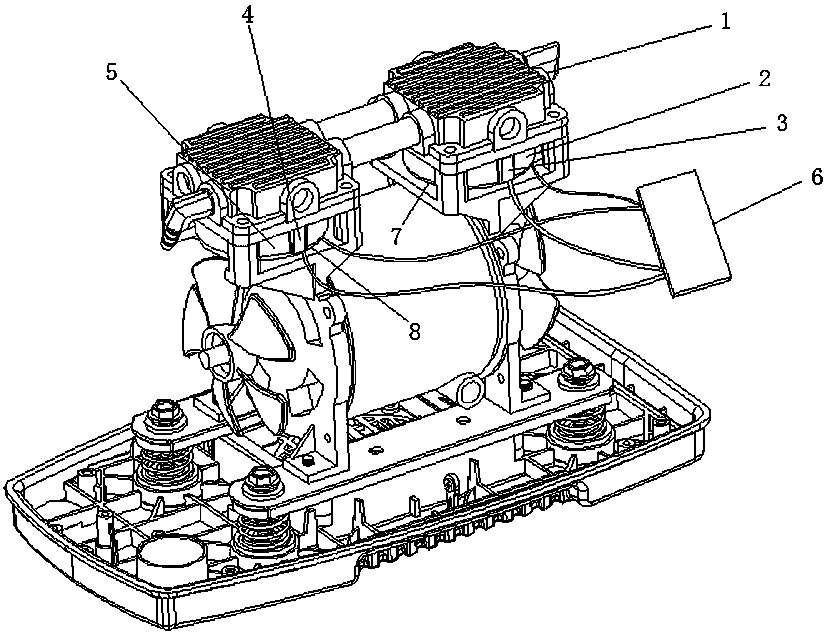

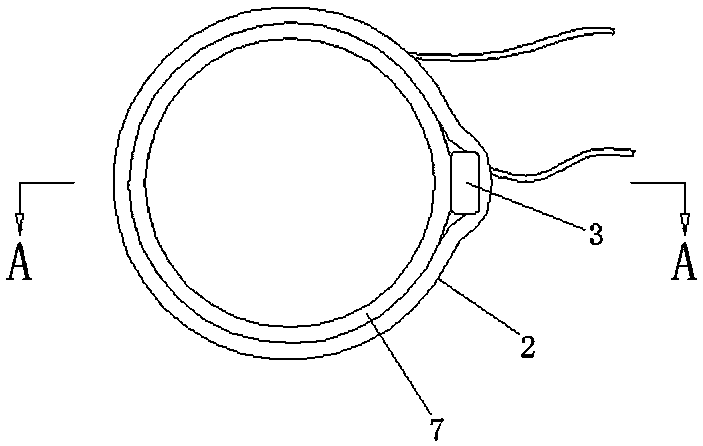

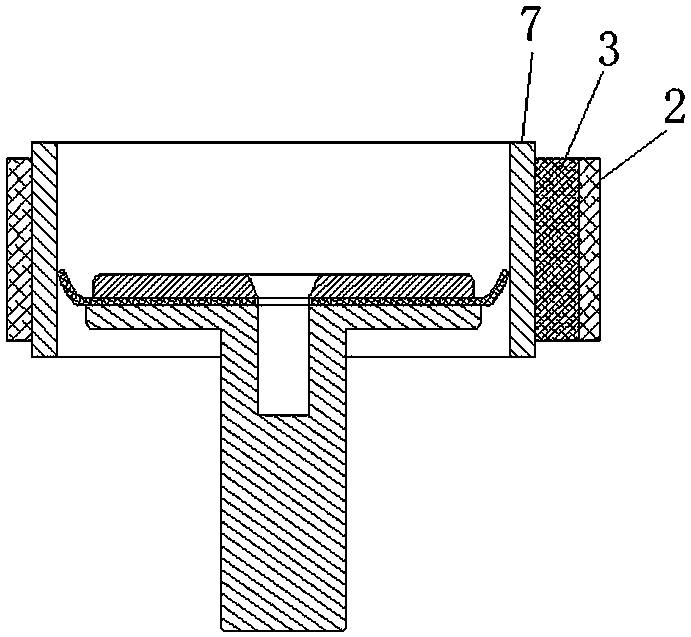

[0027] like Figure 1 to Figure 4 As shown, a preheating device for an oxygen compressor 1 includes a heating ring and a temperature sensor that are respectively placed outside the cylinder of the compressor 1. The heating ring is designed in an O-ring structure, and the temperature sensor is a contact type Temperature Sensor. The temperature sensor is located between the heating coil and the cylinder or outside the heating coil, and the heating coil and the temperature sensor are connected to the main control board 6 respectively, and the main control board 6 controls the heating coil to start and stop. 1 pre-heating device of oxygen-making compressor of the present invention is mainly made of heating ring and temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com