Rubbish compressor

A garbage compressor and garbage storage technology, which is applied in the direction of presses, garbage transmission, garbage collection, etc., can solve the problems of high manufacturing cost of the pressure head cylinder, large stroke of the driving cylinder, and difficult installation, and achieve low equipment height and stroke The effect of shortening and reducing the height space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

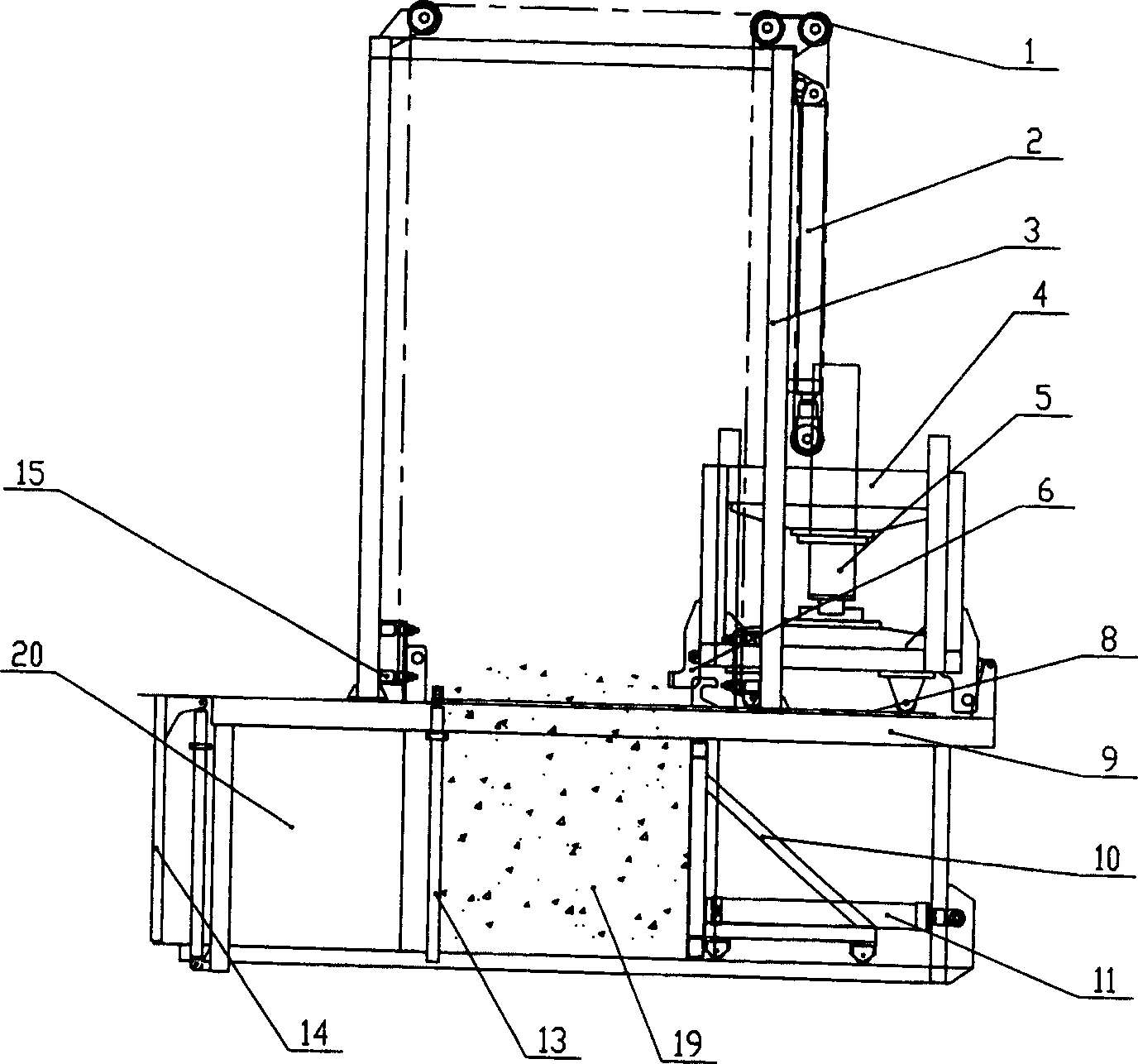

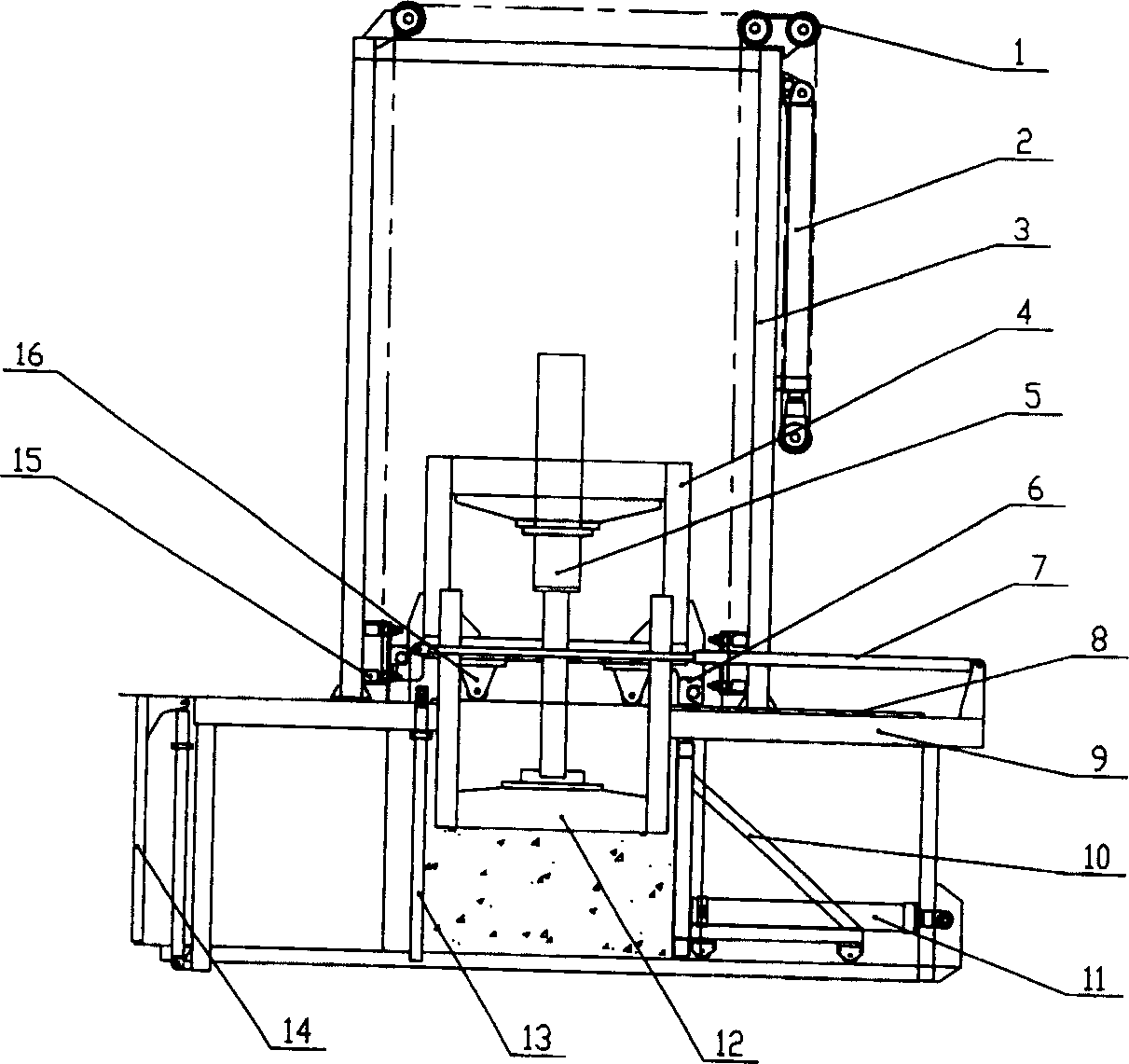

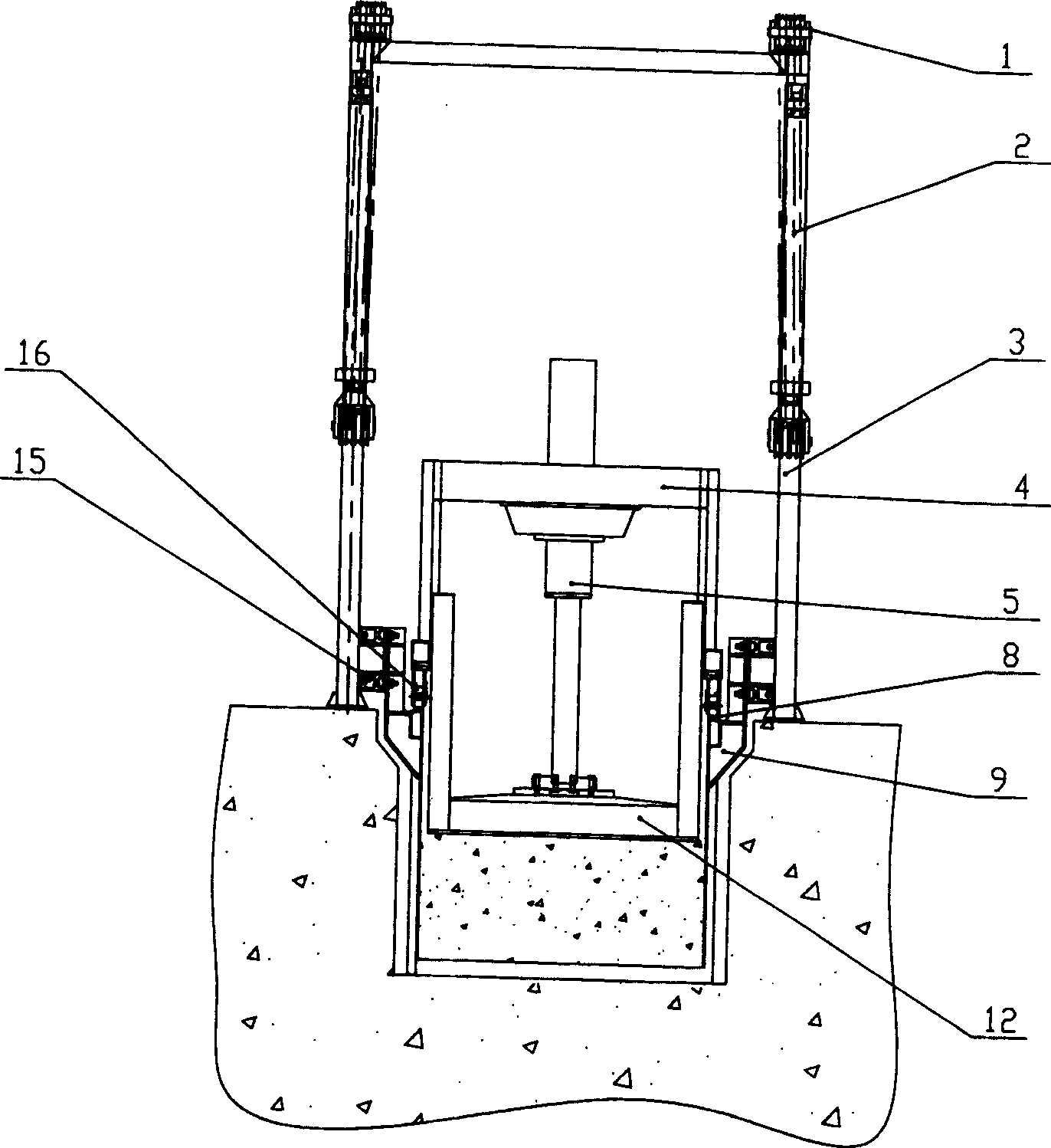

[0034] See figure 1 , The garbage compressor consists of the carrying gear train 1, carrying the carrying cylinder 2, the frame 3, the pressure head carriage 4, the compression cylinder 5, the pressure head carriage locking mechanism 6, the pressure head carriage translation cylinder 7, the pressure head carriage guide rail 8, the box The body 9, the dozer 10, the dozer cylinder 11, the indenter 12, the middle door 13, the front door 14, the box guide rail mechanism 15, the indenter trolley roller 16 and other components.

[0035] An indenter carriage rail 8 is installed on the box body 9, and the indenter carriage 4 can move back and forth along the indenter carriage guide rail 8 according to the requirements of the operation process. For example, when dumping garbage into the compression bin, the indenter carriage 4 moves to the box body 9 To the rear of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com