Method for machining gear by flexible lapped finishing

A grinding and gear technology, applied in the direction of components with teeth, belts/chains/gears, gear teeth, etc., can solve the problem that the burrs and edges on the tooth surface are difficult to eliminate, and the burrs and edges on the gear tooth surface are difficult to remove and affect. Product quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

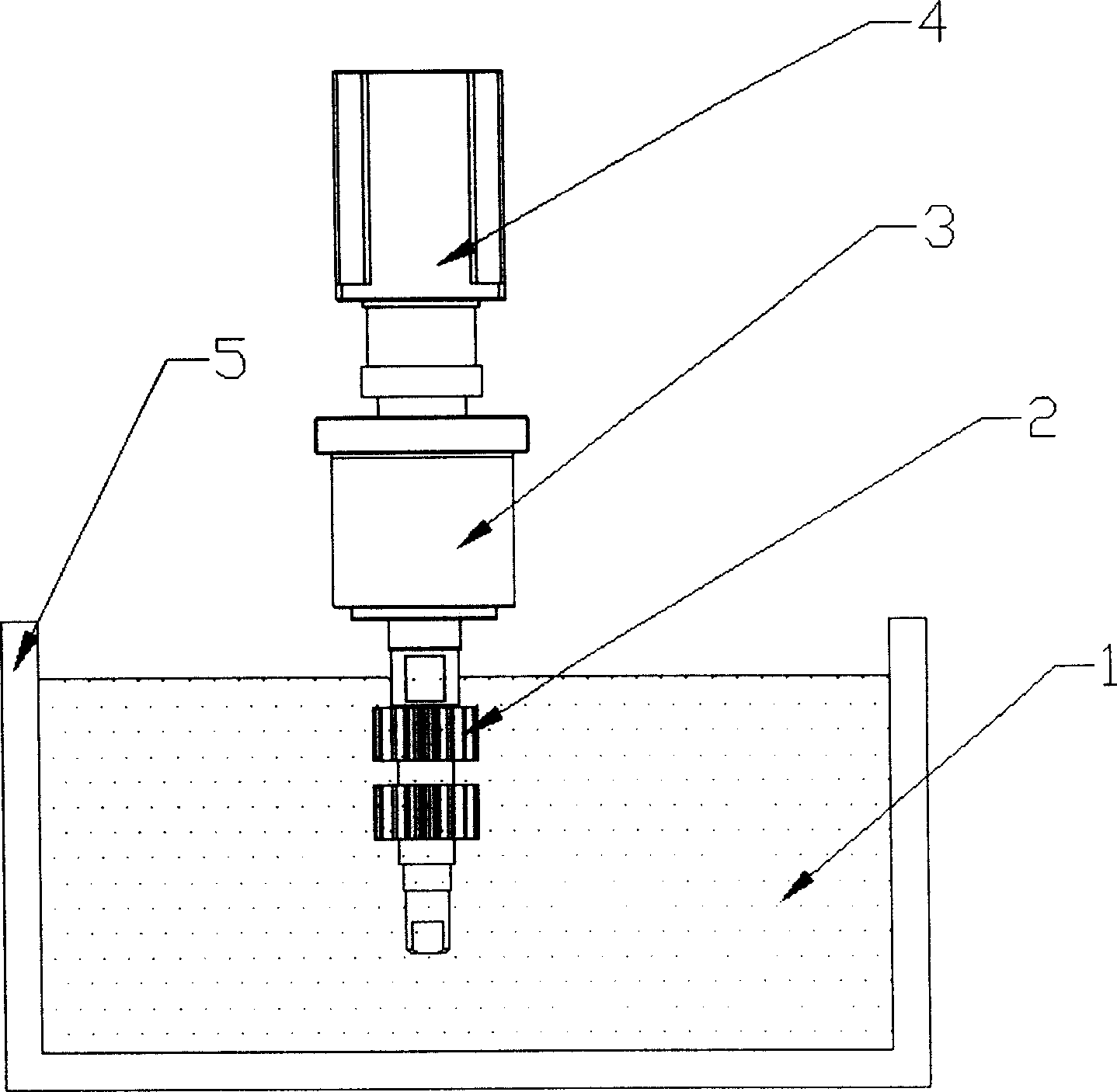

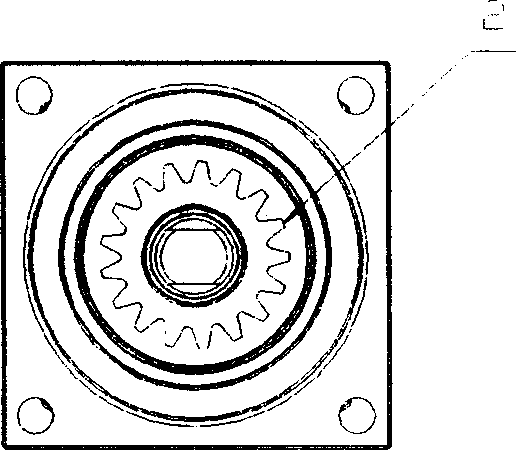

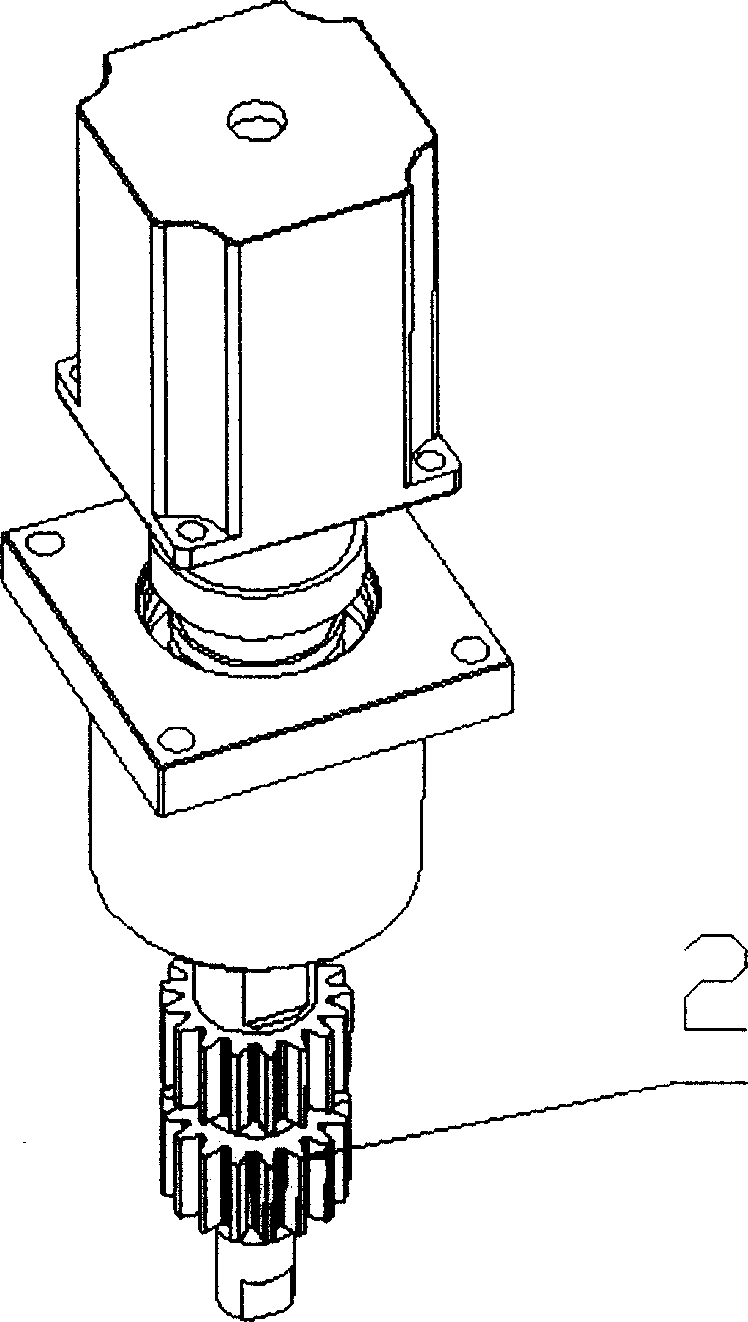

[0019] Such as figure 1 , figure 2 and image 3 Shown, put semi-fluid mortar 1 in container 5. Semi-fluid mortar 1 is made of emery, paste-like bonding material (such as flour paste), sodium nitrite and water; wherein the weight proportion of each component is emery 80%, flour paste 5%, Sodium Nitrite 1% and Water 14%. Then, the gear 2 is fixed on the shaft of the motor 4 , and the gear 2 is completely submerged in the semi-fluid mortar 1 . figure 1 Middle 3 is a bearing seat.

[0020] The starter motor 4 drives the gear 2 to rotate at a high speed in the semi-fluid mortar 1, so that the tooth part of the gear moves relative to the corundum to ensure that the linear speed of the tooth part is more than 4 meters per second, such as 5 meters per second. In this way, the corundum collides with the gear teeth at high speed, and the corundum will grind the gear teeth, and the smoother the gear surface, the smaller the resistance, that is, the less the grinding effect of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com