Solid particle erosion resistant steam turbine nozzle

A solid particle, steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as unsafe hazards, reduce unit efficiency, increase blade surface roughness and steam seal clearance, etc., to reduce maintenance costs, Erosion rate reduction and quantity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

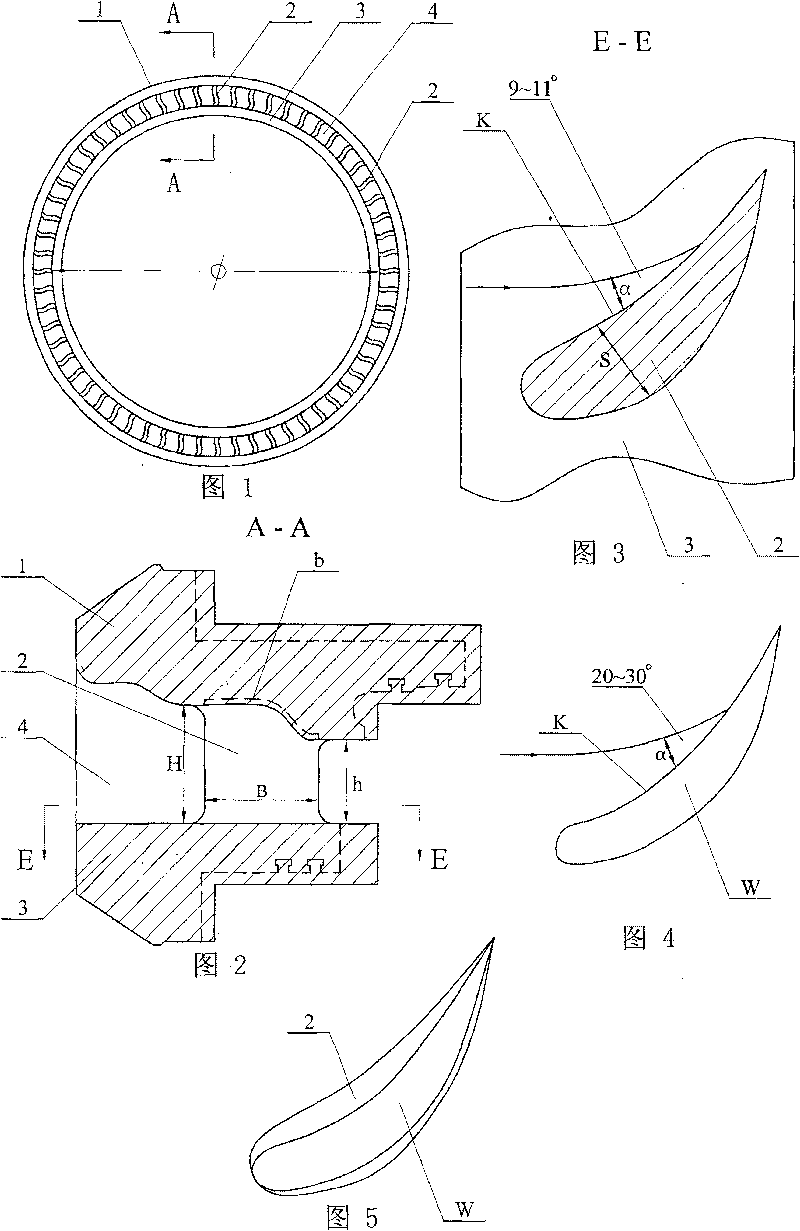

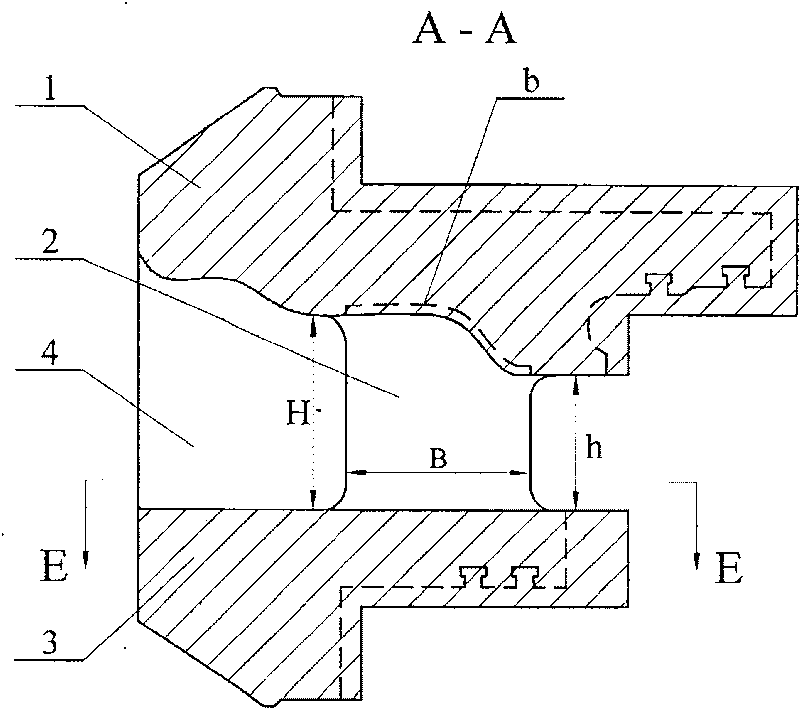

[0007] Specific implementation mode one: (see Figure 1 ~ Figure 3 ) This embodiment consists of a nozzle outer ring 1, an adjustment stage blade 2, and a nozzle inner ring 3, the nozzle inner ring 3 is arranged in the nozzle outer ring 1, and the adjustment stage blade 2 is fixed between the nozzle outer ring 1 and the nozzle inner ring 3 The space surrounded by the nozzle outer ring 1, the nozzle inner ring 3 and two adjacent regulating stage blades 2 forms a nozzle channel 4, and the solid particle impact angle a of the pressure surface K of the regulating stage blade 2 is 9-11°.

specific Embodiment approach 2

[0008] Specific implementation mode two: (see figure 1 ) The outer diameter Φ of the nozzle inner ring 3 of this embodiment is 1040 mm. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: (see figure 2 ) The axial width B of the regulating stage blade 2 in this embodiment is 76.49mm. Other compositions and connections are the same as in the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap