Hydraulic machine for producing grass mat and its grass mat production method

A pad making machine and supporting pad technology, applied in the direction of presses, flat products, manufacturing tools, etc., can solve complex problems and achieve the effects of good quality, neat appearance and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

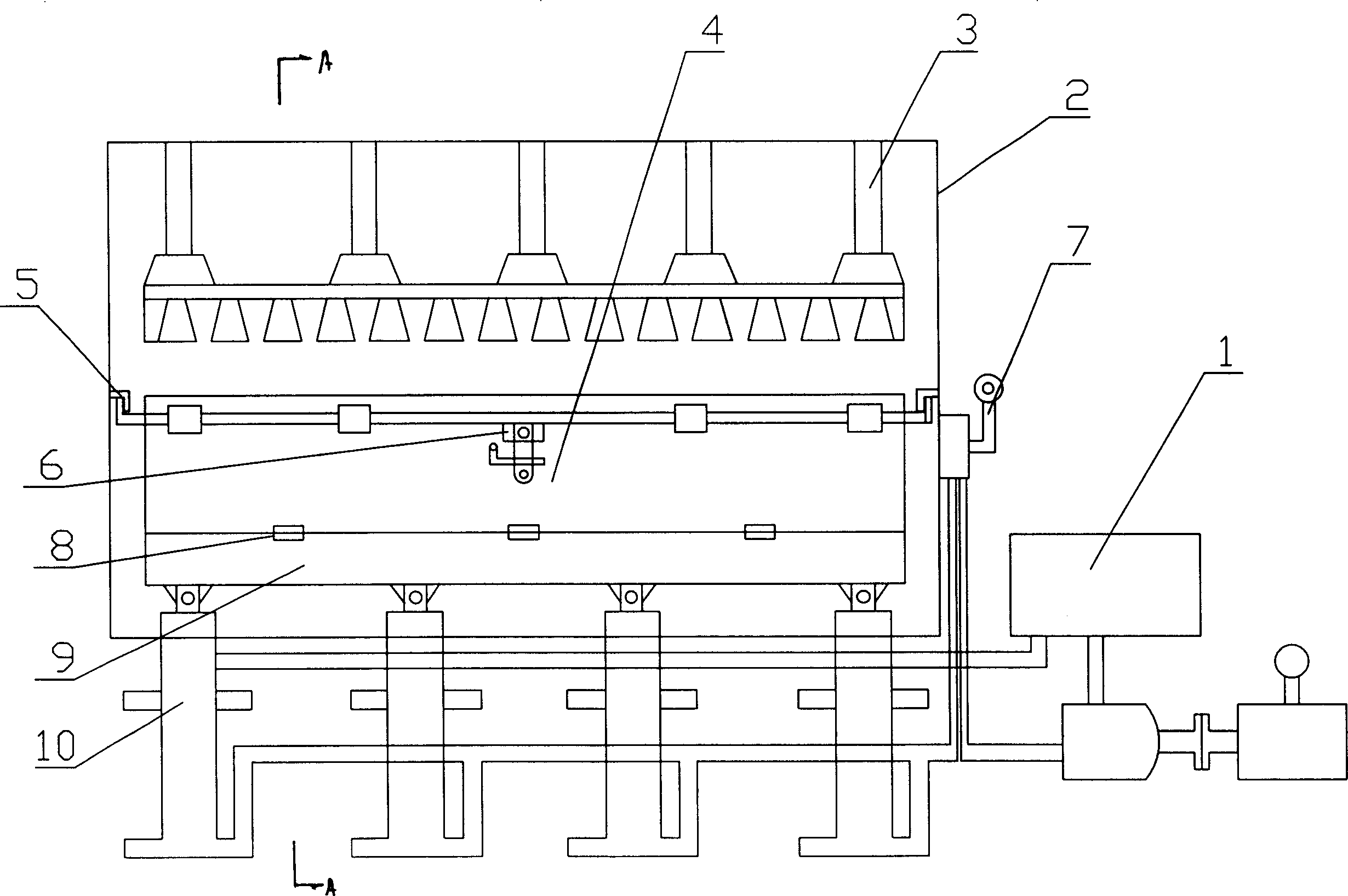

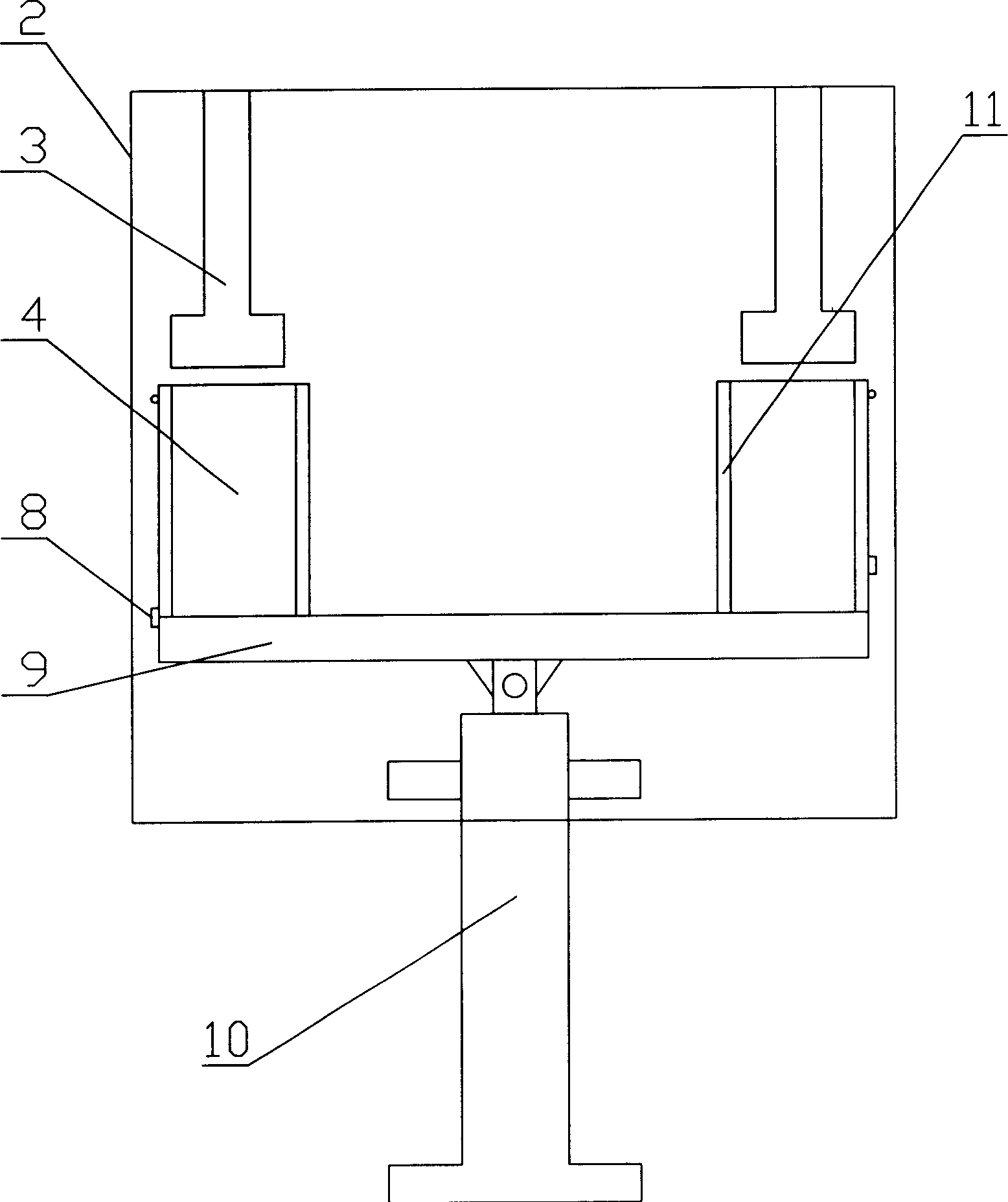

[0031] like figure 1 , figure 2 As shown, the straw pad hydraulic pad making machine of the present invention includes an electric hydraulic pump 1, a main frame 2, an oil cylinder 10, and a pad mold, and is characterized in that two sets of belts are arranged on the top beam of the main frame 2. The fixed pressure head 3 with a binding process hole is provided with an oil cylinder 10 on the bottom beam of the main frame 2. The upper end of the piston rod of the oil cylinder 10 is connected to the movable bottom plate 9, and the two sides of the upper surface of the movable bottom plate 9 are connected with the hinge 8. The dodge door of the movable base plate 9 and the inner formwork 11 fixed on the movable base plate 9 with the binding process hole corresponding to the fixed pressure head form the support mold 4, and the outer movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com