Method of manufacturing motorcycle and tank-in frame of motorcycle

A technology of an automatic two-wheeled vehicle and a manufacturing method, which is applied in the directions of bicycle frames, motor vehicles, bicycles, etc., can solve the problems of ineffective utilization, etc., and achieve the effect of easy leak testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

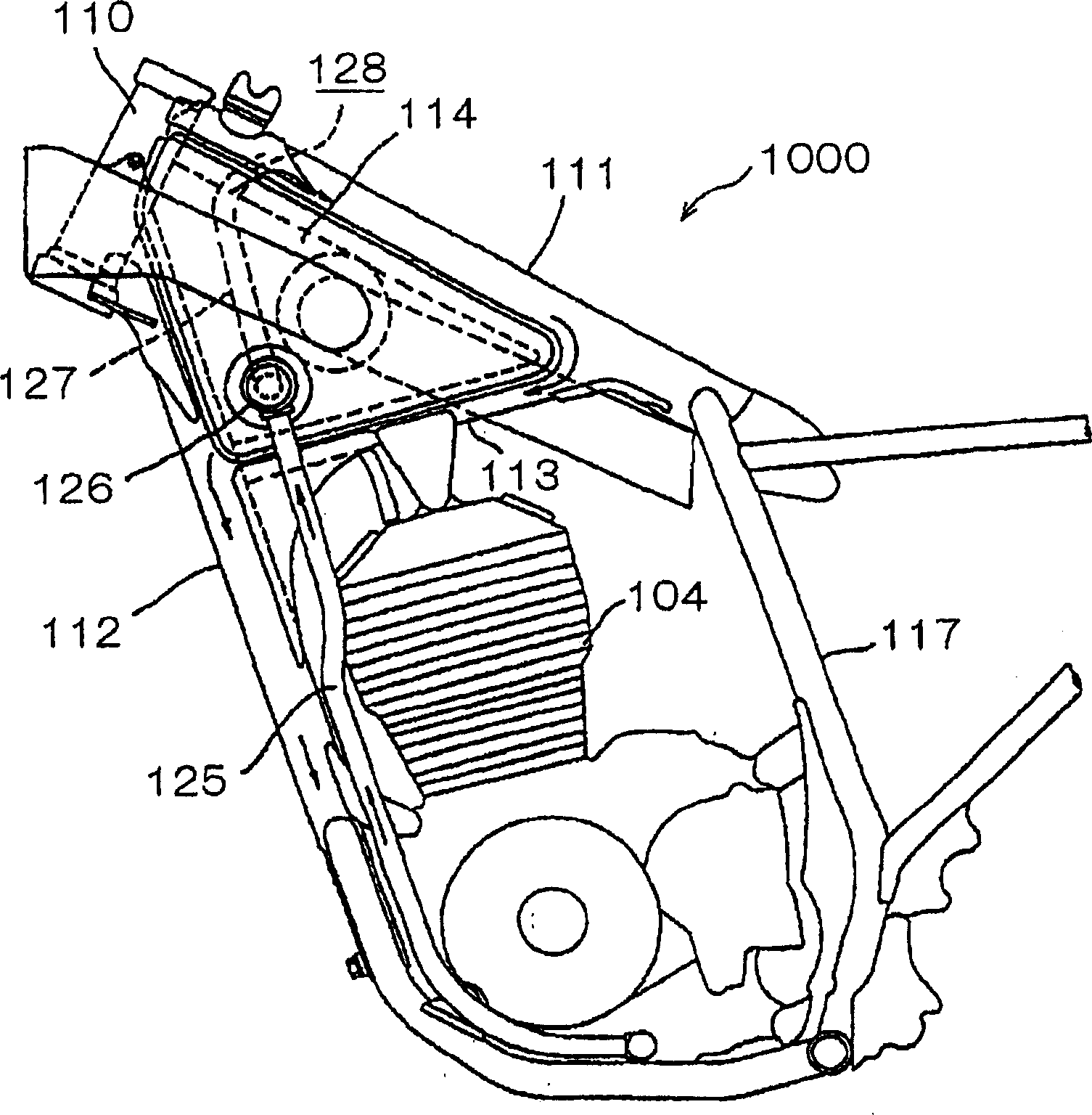

[0080] The inventors of the present invention worked hard to solve the above problems, and came to the conclusion that the main frame (main frame) required for the oil tank constituting the frame inner tank was removed, and the manufacture of the frame inner box was completed using parts other than the main tube. Thus, the present invention is constituted.

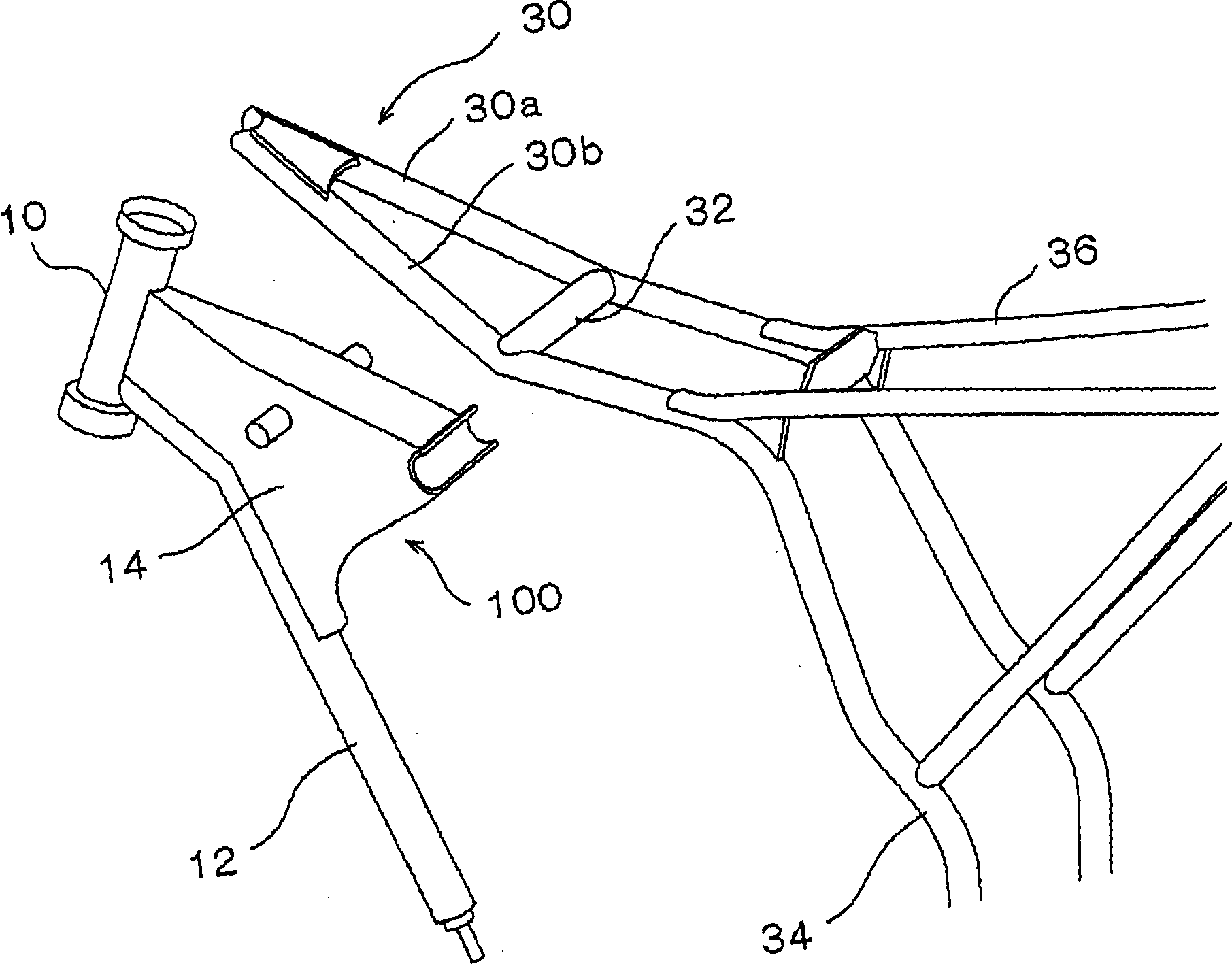

[0081] Embodiments of the present invention are described below with reference to the drawings. In the following drawings, in order to simplify description, the same reference numerals are used to denote constituent elements having substantially the same functions. Furthermore, the present invention is not limited to the following embodiments.

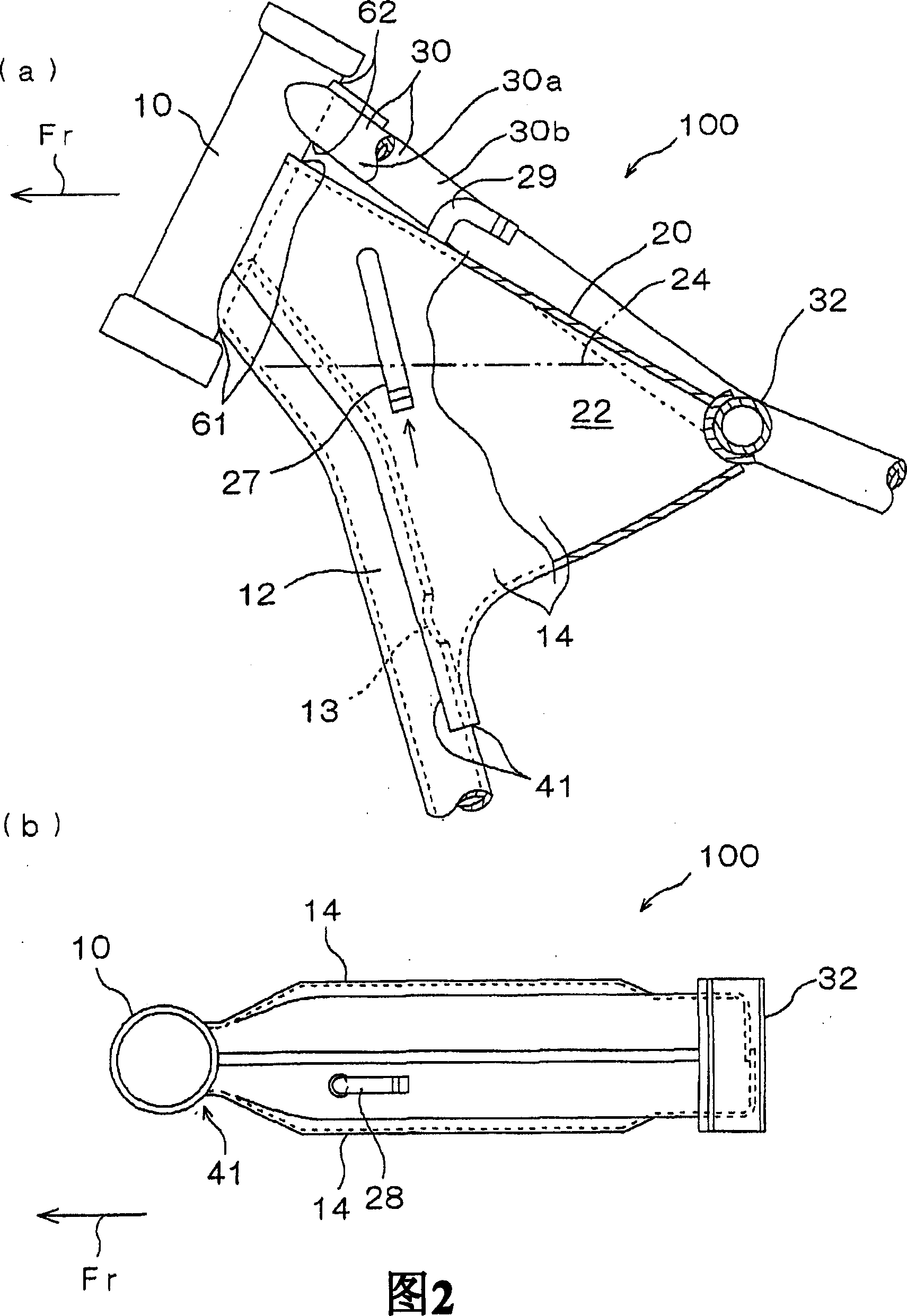

[0082] Hereinafter, the frame inner box 100 of the motorcycle according to the embodiment of the present invention will be described with reference to FIG. 2( a ) and FIG. 2( b ). FIG. 2( a ) is a side view schematically showing the structure of the frame inner box 100 according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com