Eyelet light pole with high stagnation

An articulated, light-pile technology, applied to fixed lighting devices, non-magnetic metal hulls, motor vehicles, etc., can solve the problem of ice floes stuck or forcibly towed away, complicated universal articulated joint structure, and inconvenient to use and maintain. and other problems, to achieve the effects of excellent physical properties and processing properties, light structure, and small impact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

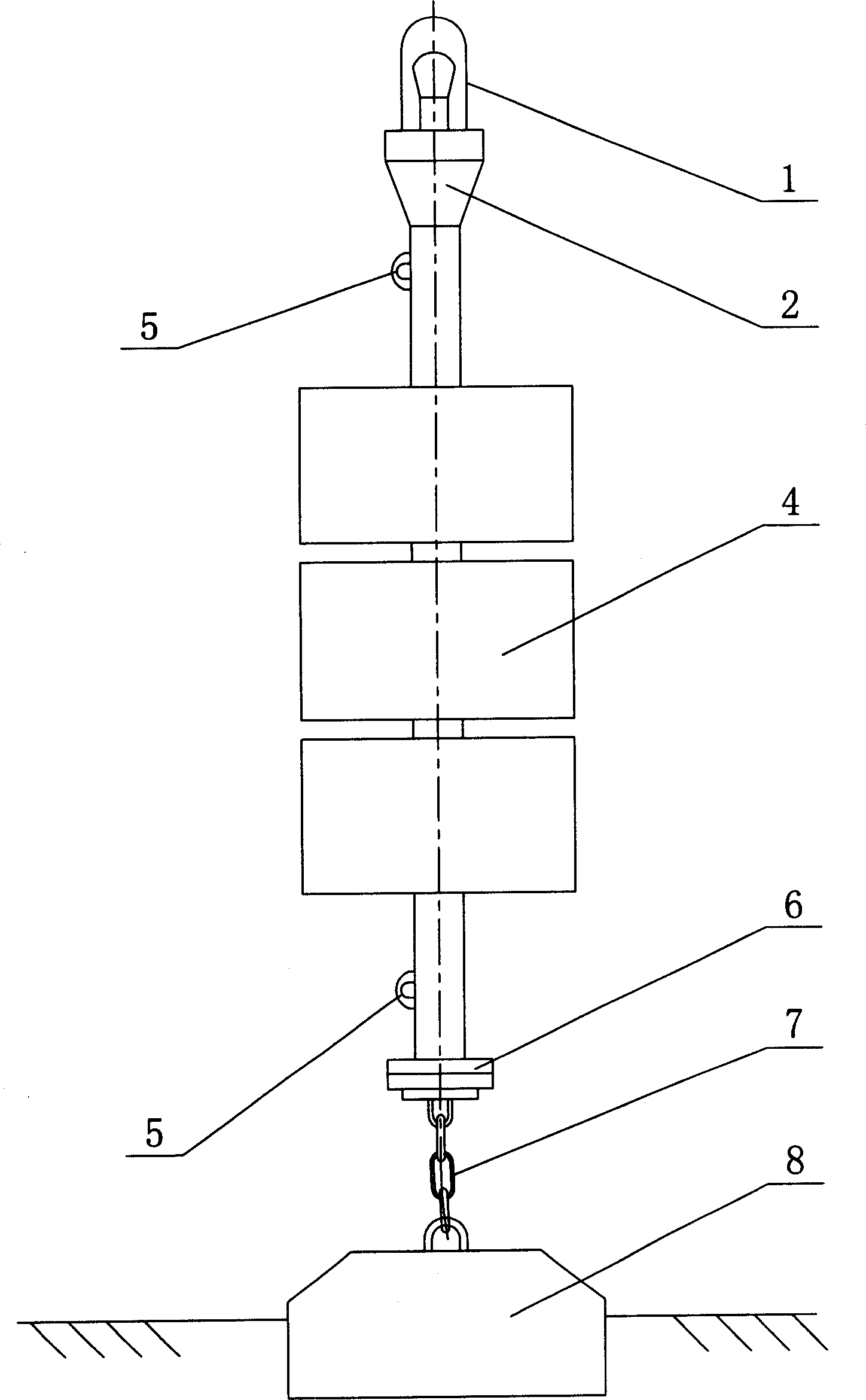

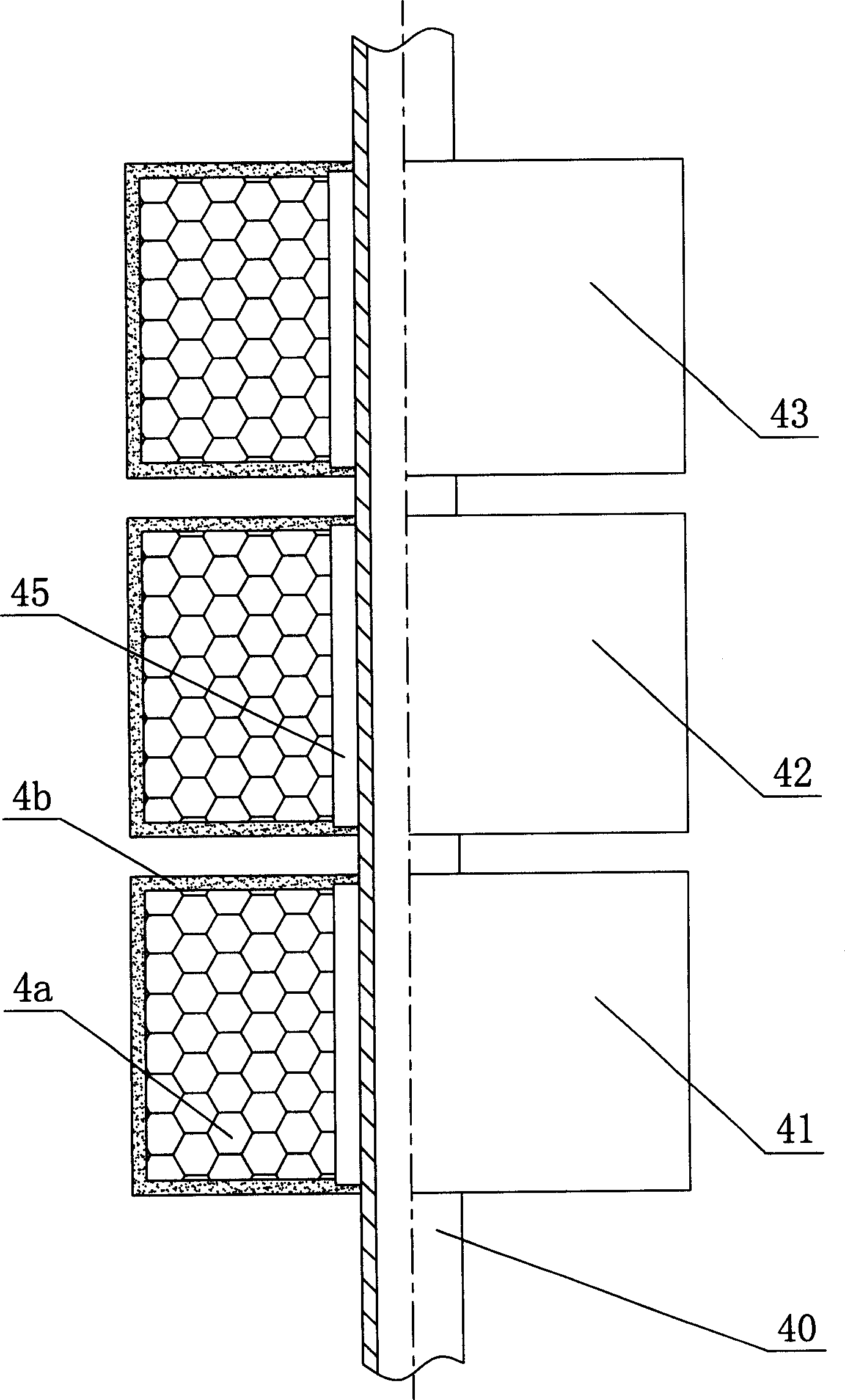

[0019] Such as figure 1 , figure 2 As shown, the present invention includes a lamp 1, an ice guiding skirt 2, a floating chamber 4, two suspension rings 5, a counterweight 6, an anchor chain 7, and sinking stones 8. The floating chamber 4 includes a core tube 40, three floating bodies 41, 42, 43, the floating body 41, 42, 43 is fixed in series on the periphery of the core pipe 40 through the central hole, and the floating body 41, 42, 43 is composed of the elastic foam inner core 4a and coated on the elastic foam inner core 4a surface of the elastic armor 4b, there is no gap between the elastic foam core 4a and the elastic armor 4b, the two ends of the anchor chain 7 are respectively connected to the bottom end of the core tube 40 and the sink through the connecting piece. The anchor chain 7 is a short anchor chain, and the anchor chain 7 includes three chain links. The surface of the chain rings is provided with a wear-resistant protective layer, and the material of the wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com