Clutch brake

A brake and clutch type technology, applied in the hoisting device and other directions, can solve the problems of unsafety, inconvenient operation, low efficiency, etc., and achieve the effect of strong adaptability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

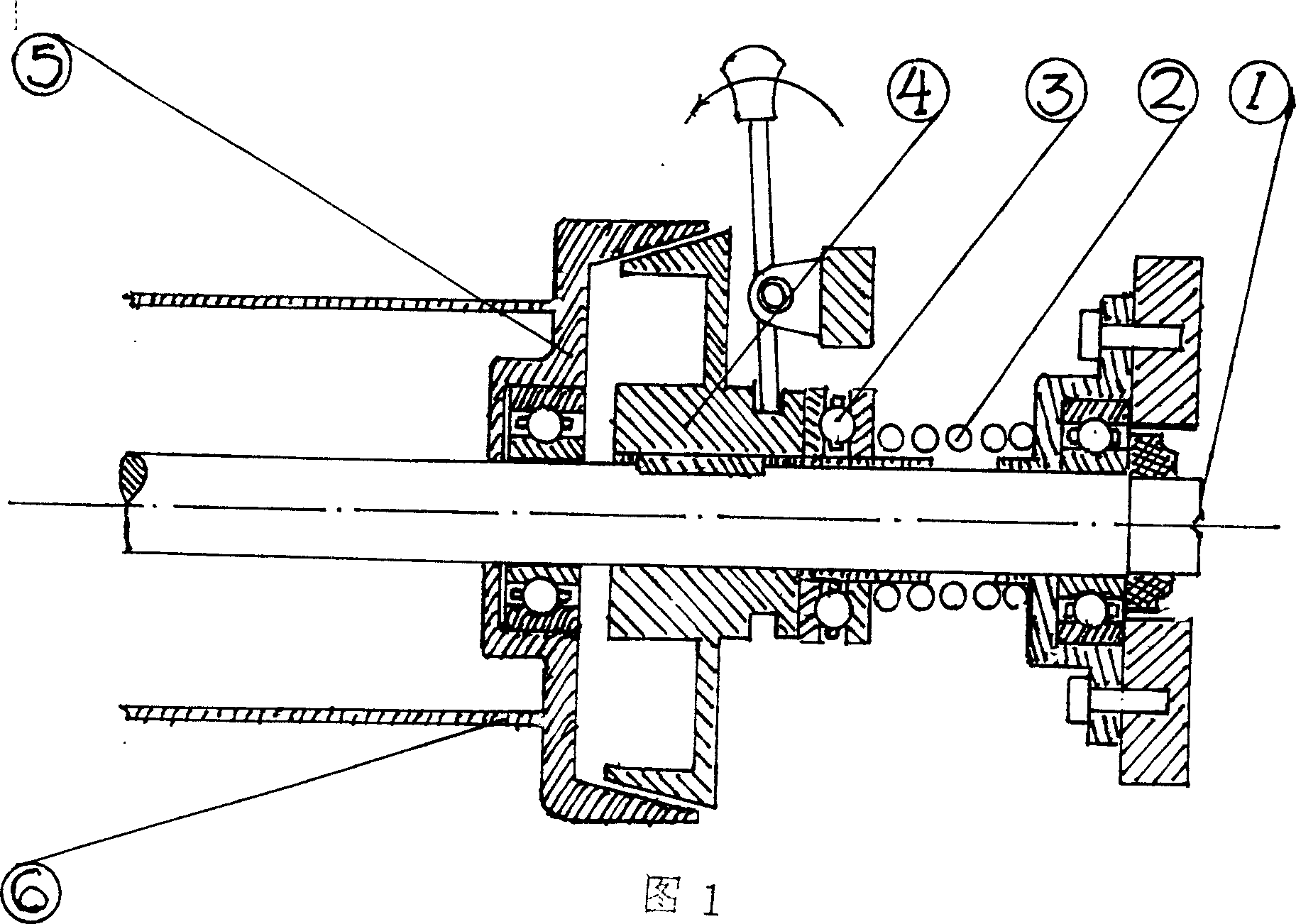

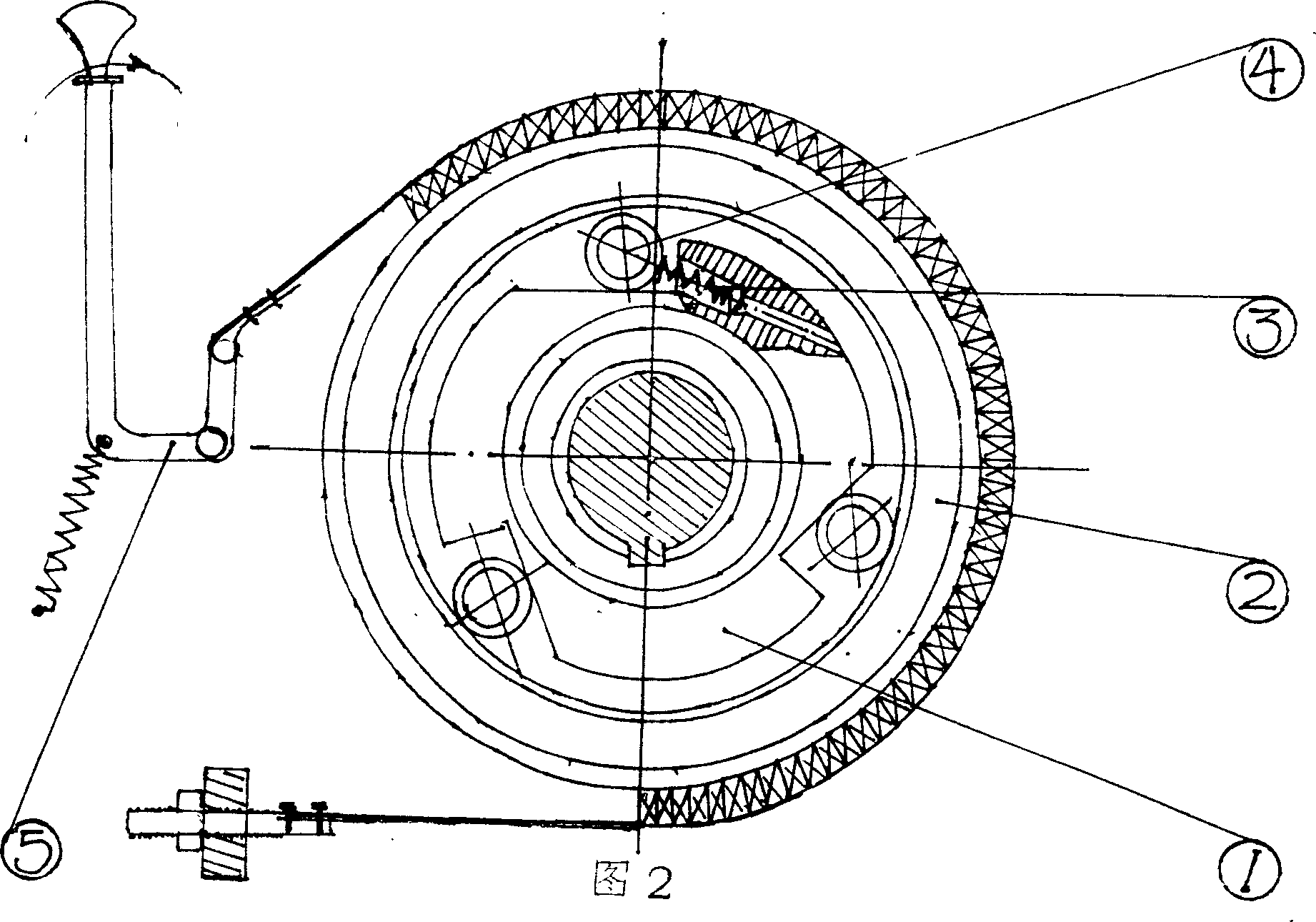

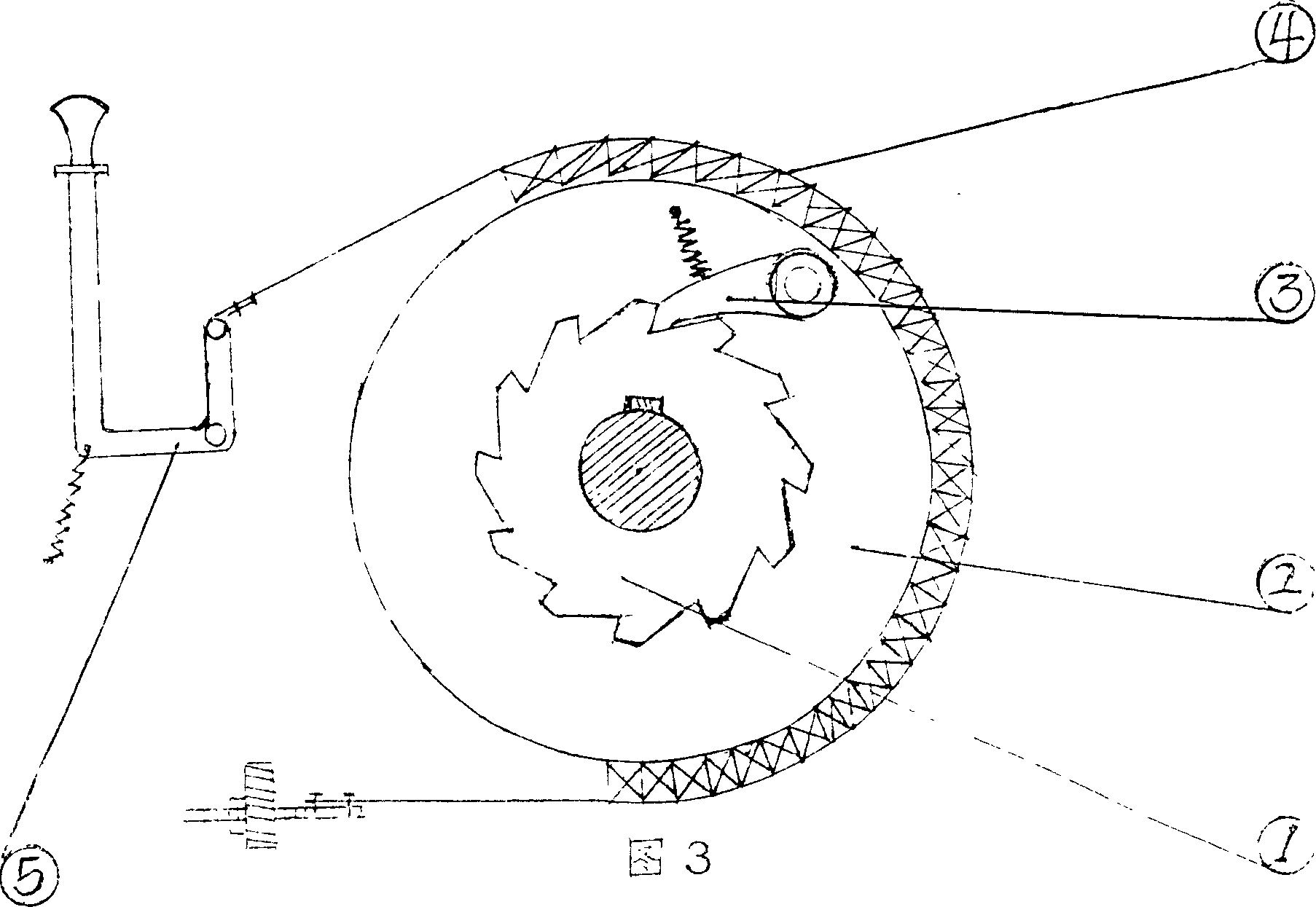

[0012] In Fig. 1, 1. output shaft; 2. spring; 3. thrust bearing; 4. inner cone; 5. outer cone; 6. reel.

[0013] The output shaft ① is obtained by connecting the shaft coupling with the worm gear shaft or directly lengthening the worm gear shaft. The two ends of the spring ② are respectively set between the thrust bearing ③ and the bearing seat, the thrust bearing ③ is set on one end of the inner cone ④, and the inner cone ④ is set on the output shaft ① by a guide flat key or a spline. Outer cone 5. is fixed on one end (or cast into one) of reel 6. is combined with output shaft 1. by bearing. In the stopped position, due to the thrust of the spring, the inner and outer cones are in a joint state, and the reel rotates with the output shaft under the action of friction torque. If the handle is pushed to the left, the inner and outer cones are in a separated state, and the reel The cylinder can be rotated arbitrarily, because the worm and worm gear have the ability of "self-lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com