Winding apparatus for divided stator core

A technology of stator iron core and winding device, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of complicated operation, poor handling of iron core components, and poor operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

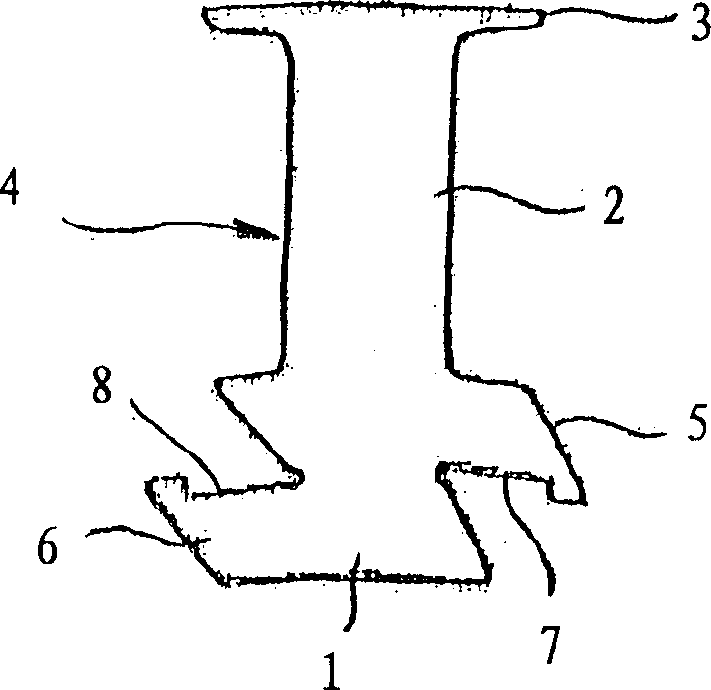

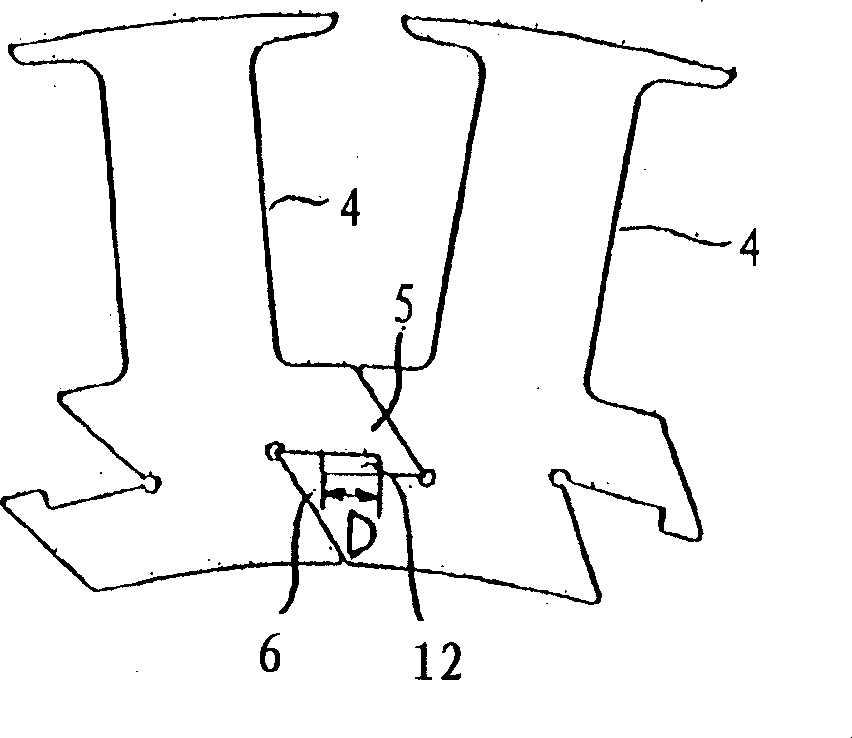

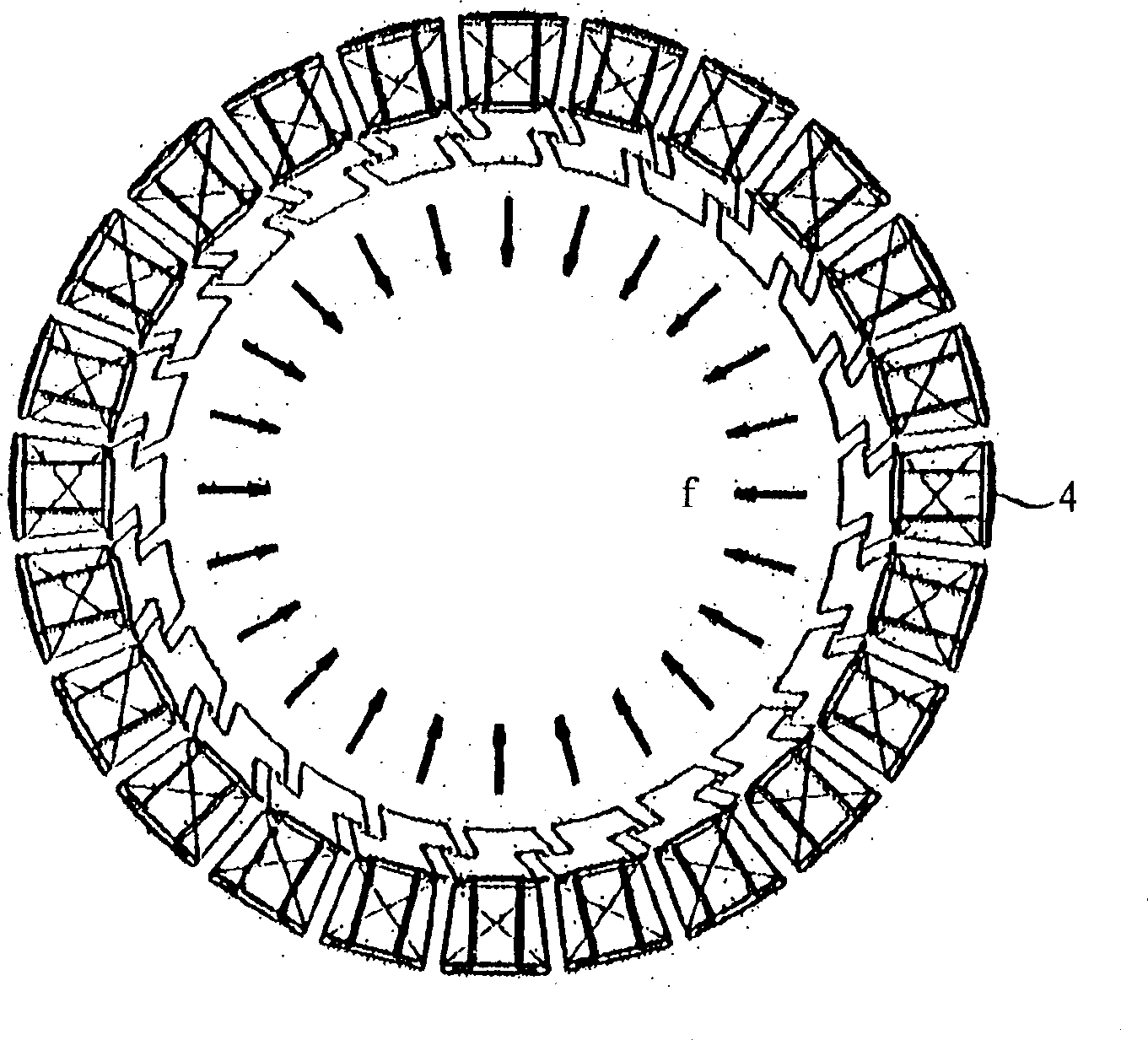

[0026] The coil winding device for split stator core of the present invention, while stepping and conveying a magnetic pole through the drive shaft, the stator core mounted on the drive shaft passes the copper wire between the claws, and winds and installs the coils sequentially and continuously In the magnetic pole part, there is a mechanism for partially expanding the stator core outward sequentially. The stator core and the drive shaft rotate synchronously to combine the various core elements with each other along the circumferential direction within a specified range. Specifically, structured as Figures 6 to 10 shown.

[0027] The mechanism is composed of the following parts: a circular pedestal 13 integrally installed on the drive shaft 12; a rod 15, which is slidably mounted on the pedestal 13 in the direction of the center of the circle through a sliding member 14, and is arranged to Each core element 4 of the divided stator core 9 is opposed to and respectively abutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com