Method for tolerance design qualitative simulation of sedan body

A technology for car body and tolerance, which is applied in the field of qualitative simulation of tolerance design of car body, and can solve problems such as incapability of qualitative simulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0030] According to content of the present invention provide specific embodiment: a kind of method for the tolerance design qualitative simulation of S6460 type concept car is as follows:

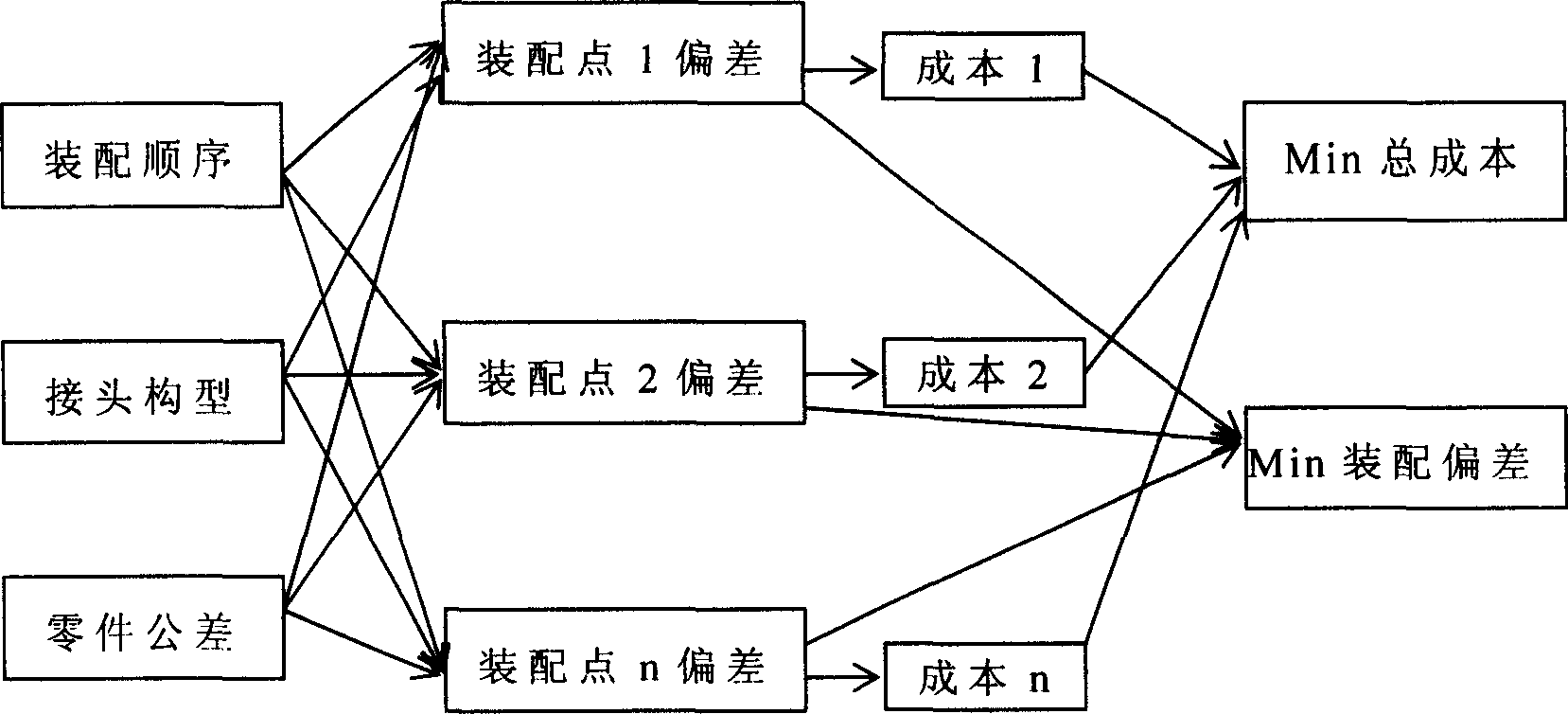

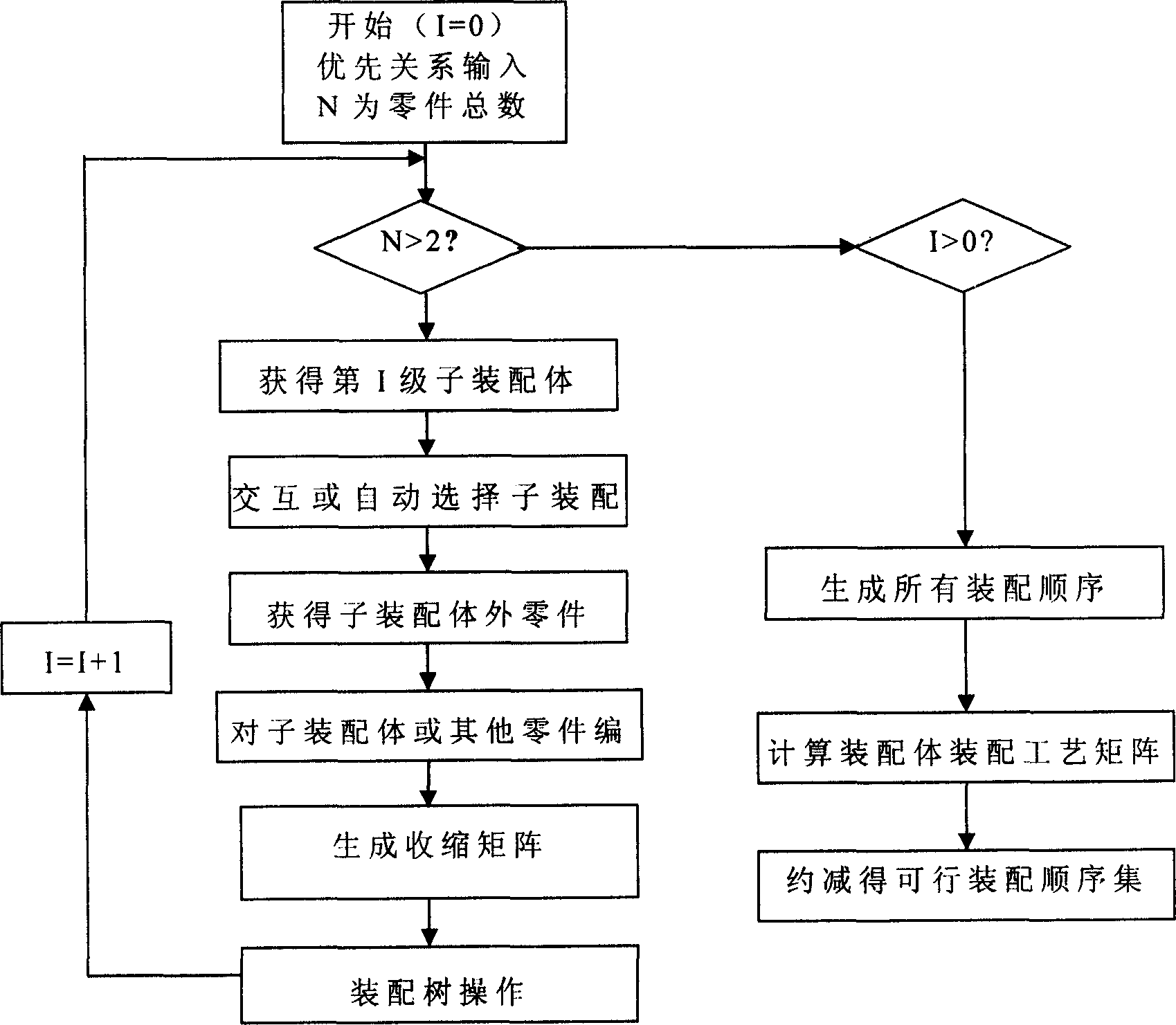

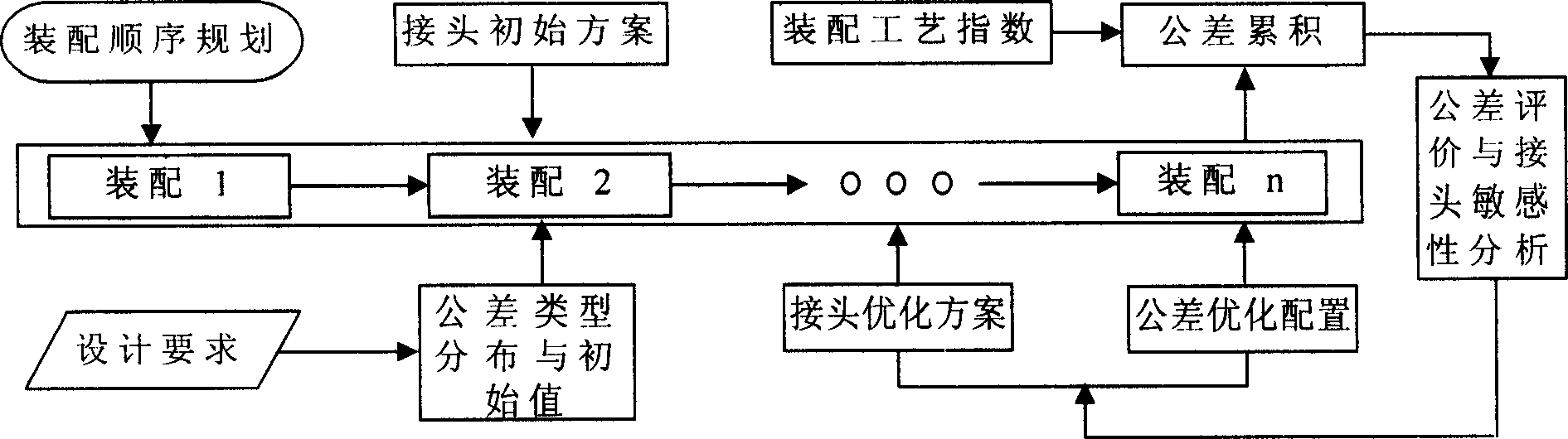

[0031] a. If figure 1 As shown, first generate the assembly sequence set, as shown in Figure 5 As shown, the assembly parts are first imported from the model database, each part is numbered with numbers 1, 2, 3..., and the correlation matrix and priority relationship matrix are extracted by human-computer interaction, and the sub-assembly is judged in the form of series and parallel through the contraction matrix After that, all feasible assembly sequences are generated. For the specific steps of the feasible assembly sequence generation process, see figure 2 , extract the qualitative information of the assembly from the attribute database, and generate the assembly process index matrix by using the qualitative information to reduce the assembly sequence as Figure 4 shown.

[0032] b....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com