Compressor impeller structure

A compressor blade and blade technology, which is applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of unsmooth operation of blades 40, shortened parts life, friction noise, etc., so as to improve reliability, prevent noise, Anti-friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

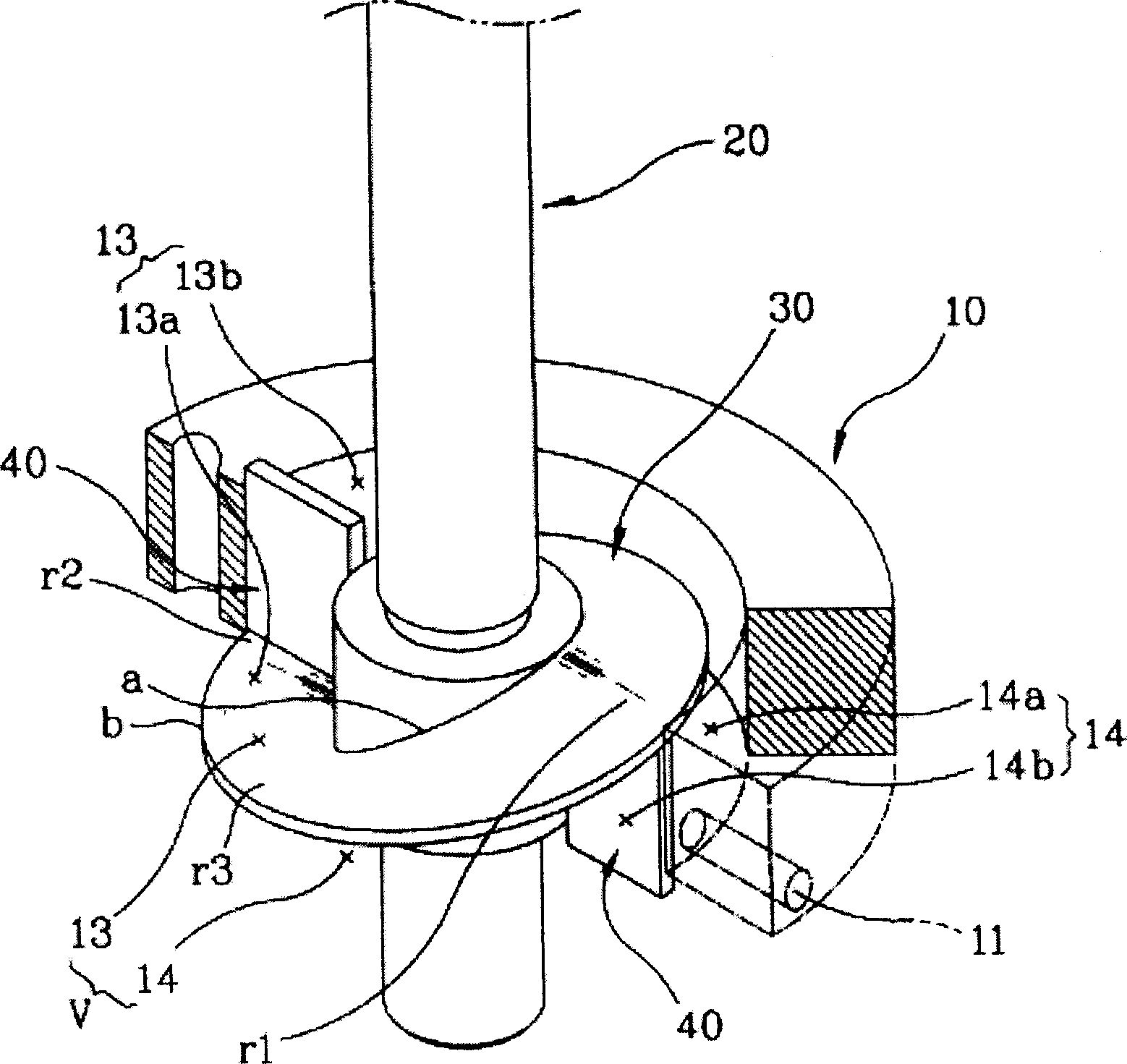

[0027] With reference to accompanying drawing, describe in detail about the blade structure of compressor of the present invention as follows:

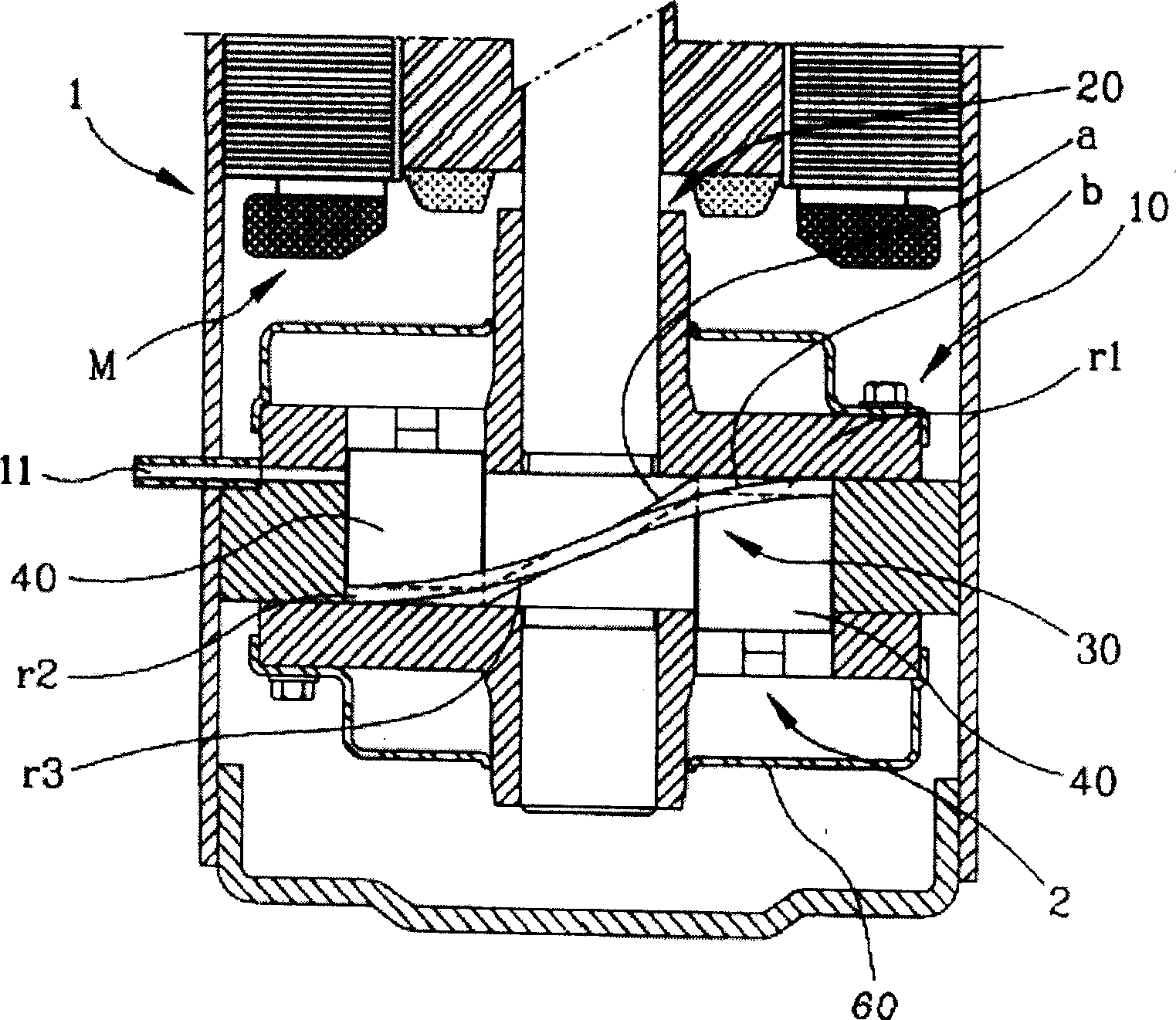

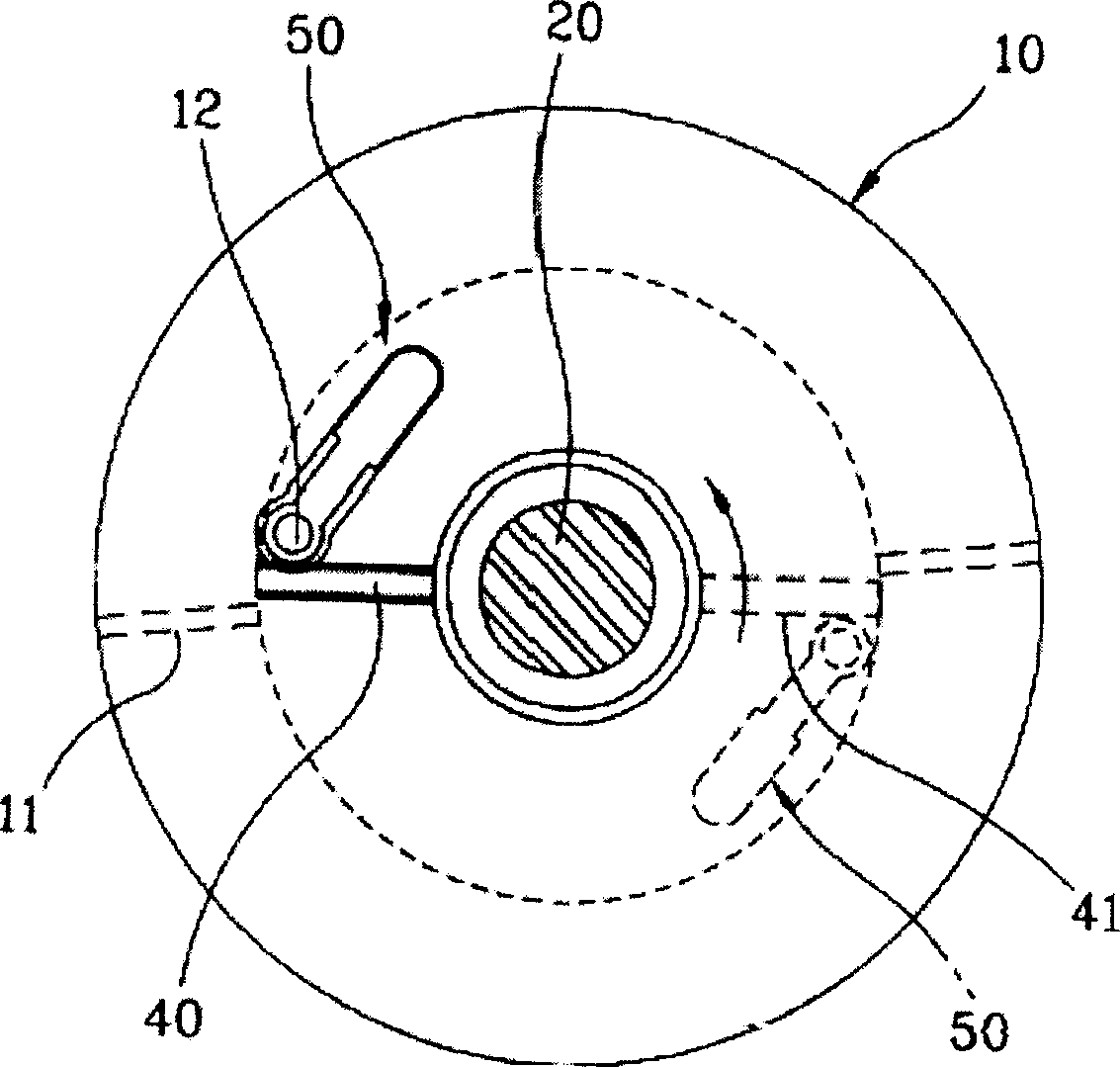

[0028] Figure 5 , 6 is an illustration of a compression mechanism part of a compressor showing the compressor blade structure of the present invention. It includes a cylinder assembly 10 with an internal space V and a suction flow path 11 communicating with the internal space V and a discharge flow path (not shown); The rotating shaft 20; the internal space V of the cylinder assembly 10 is rotatably connected with the rotating shaft 20 and isolates the internal space V into the first and second space 13, 14 isolation plate 30; Spaces 13 and 14 are inserted into the above-mentioned cylinder assembly 10 in contact with the isolation plate 30 and perform linear reciprocating motion in the axial direction with the rotation of the rotating shaft 20. The above-mentioned first space 13 and second space 14 are respectively converted into su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com