Compositions containing polyphenylene ether and/or polystyrene having improved tribological properties and methods for improving tribological properties of polyphenylene ether and/or polystyrene compo

A technology for polystyrene, friction properties, applied in the field of compositions having improved friction properties comprising polyphenylene ether and/or polystyrene and improving the friction properties of polyphenylene ether and/or polystyrene compositions, Ability to resolve issues such as unjustifiable increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A-H

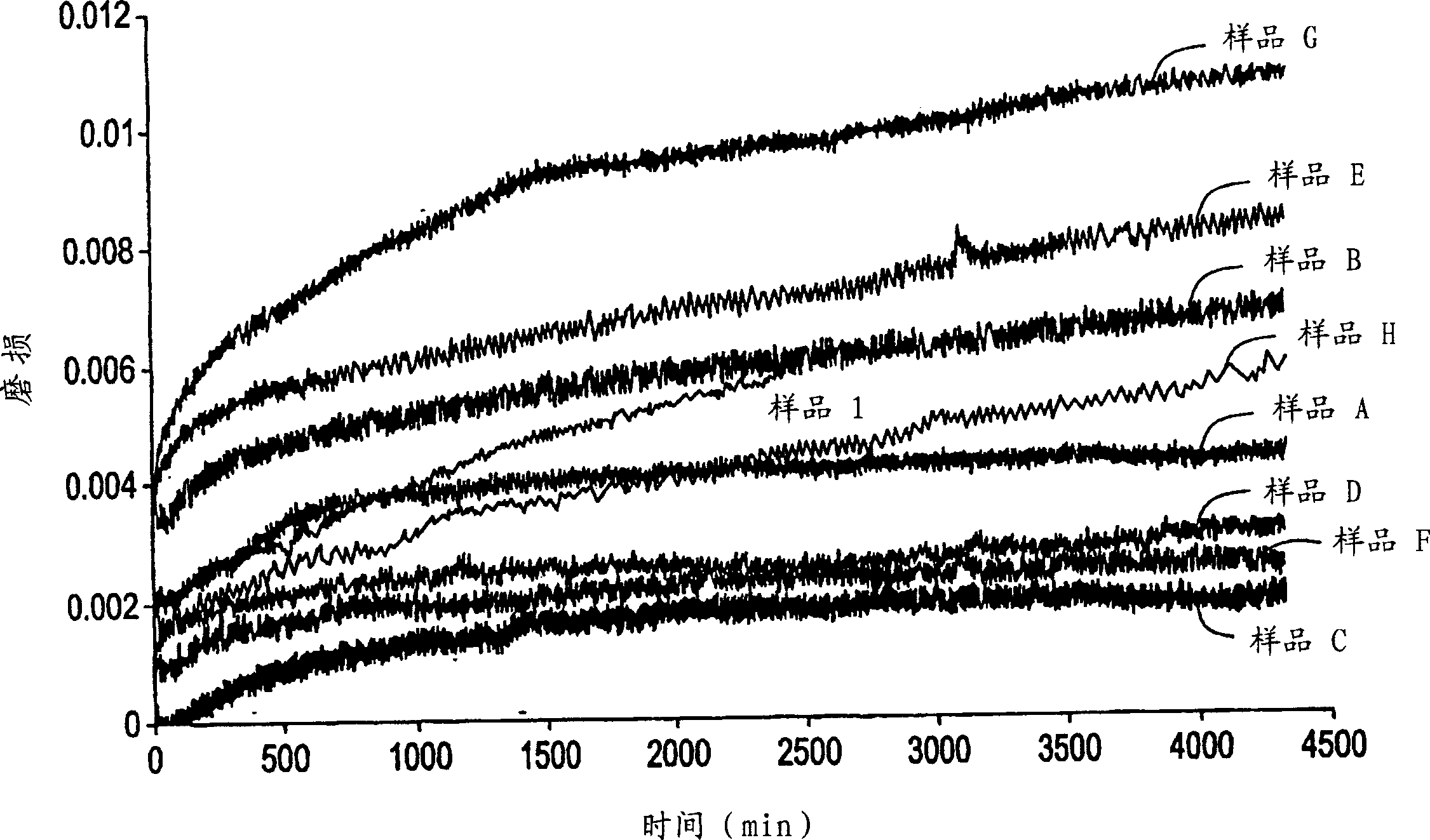

[0041] Eight compositions were prepared by blending base polymers comprising a 1:1 blend of polyphenylene ether / styrene, polyolefin, and compatibilizer. The base polymer is Noryl 731 or Noryl EN185 (sold by General Electric), where the "EN 185" blend contains a flame retardant. For compatibilizers, including polystyrene-ethylene-butadiene-styrene (SEBS) grade Kraton TM G2705 or G1651 (sold by Kraton Polymer). Finally, the polyolefin is linear low density polyethylene (LLPDE) (Petrothene GA818-07, sold by Equistar) or polyethylene / polypropylene (PE / PP) copolymer (C105-02, sold by Dow Chemical). Each composition contained 7.5 wt% or 15 wt% total polyolefin and compatibilizer in a 2:1 ratio of polyolefin to compatibilizer. The relative amounts of the components of each composition, designated A-H, are shown in Table 1.

[0042] Compositions were prepared by hand blending using Werner Pfleiderer ZSK-40 TM Extruded by twin-screw extruder, then pelletized. The extruded c...

Embodiment I

[0046] Compositions were prepared by the above method using 100% polystyrene as base polymer, 15% SEBS (Kraton G1651 ) as compatibilizer and 10% LLDPE as polyolefin. The wear data for the resulting compositions are shown in Table 1 and figure 1 . 3900 x 10 with pure polystyrene -11 mm 5 / Pa-m compared, the wear coefficient of composition I is 59×10 -11 mm 5 / Pa-m. This demonstrates that the friction properties of pure polystyrene can be improved by incorporating suitable polyolefins and compatibilizers.

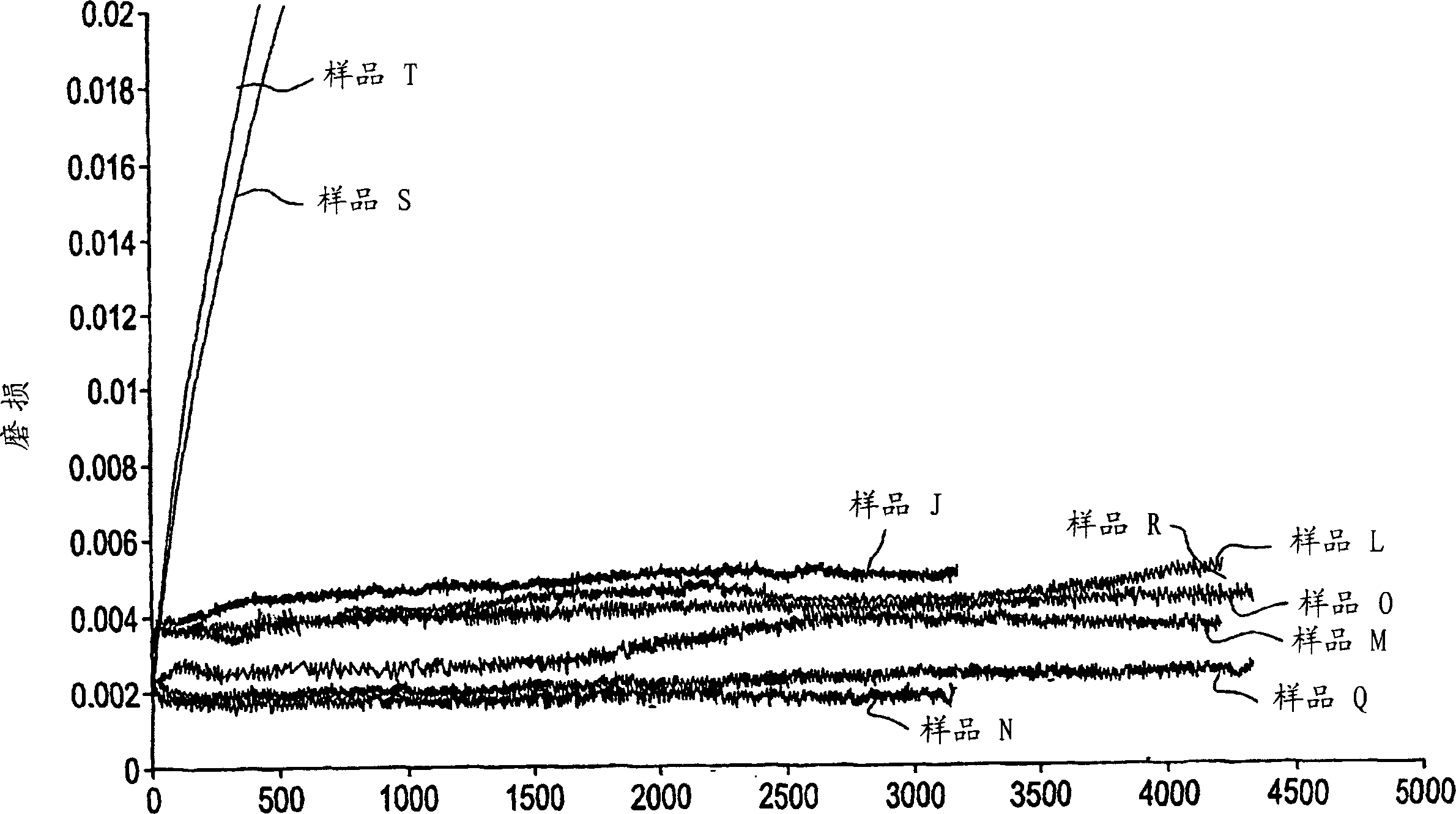

Embodiment J-Q

[0048] A 1:1 polyphenylene ether / styrene blend was used as the base polymer (Noryl 731), SEBS (Kraton TM G1651) as compatibilizer and LLDPE (Petrothene GA818-07) as polyolefin 8 further compositions were prepared by the method described above. Each composition comprises between 2 and 30 wt% polyolefin, 0-6 wt% compatibilizer, the ratio of polyolefin to compatibilizer is from 30:0 to 2:1. The relative amounts of the ingredients of each composition are shown in Table 2. Properties were evaluated as previously described and are listed in Table 2, graphically shown in figure 2 middle.

[0049] Samples J, L, M, and N all contained 10% polyolefin, and increasing the concentration of compatibilizer from 0 to 5 wt%, all exhibited -11 mm 5 Favorable wear coefficient between / Pa-m. These samples also demonstrate that increasing the concentration of compatibilizer improves impact strength, as evidenced by an increase in the notched Izod value. Specifically, Noryl The 731 ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com