Measuring method of on line key paramotor based on new type generalized predictive control

A generalized predictive control and key parameter technology, which is applied in the direction of measuring devices, instruments, special recording/indicating devices, etc., can solve problems such as zirconia measurement lag, failure to meet the requirements of time domain adaptation between measurement and control, and measurement lag. Achieve the effect of reducing computational complexity, realizing real-time online soft measurement, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

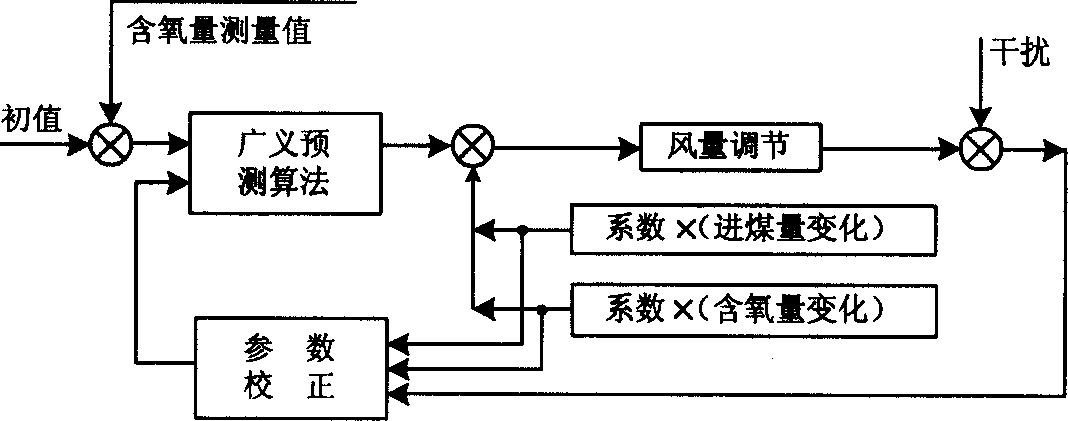

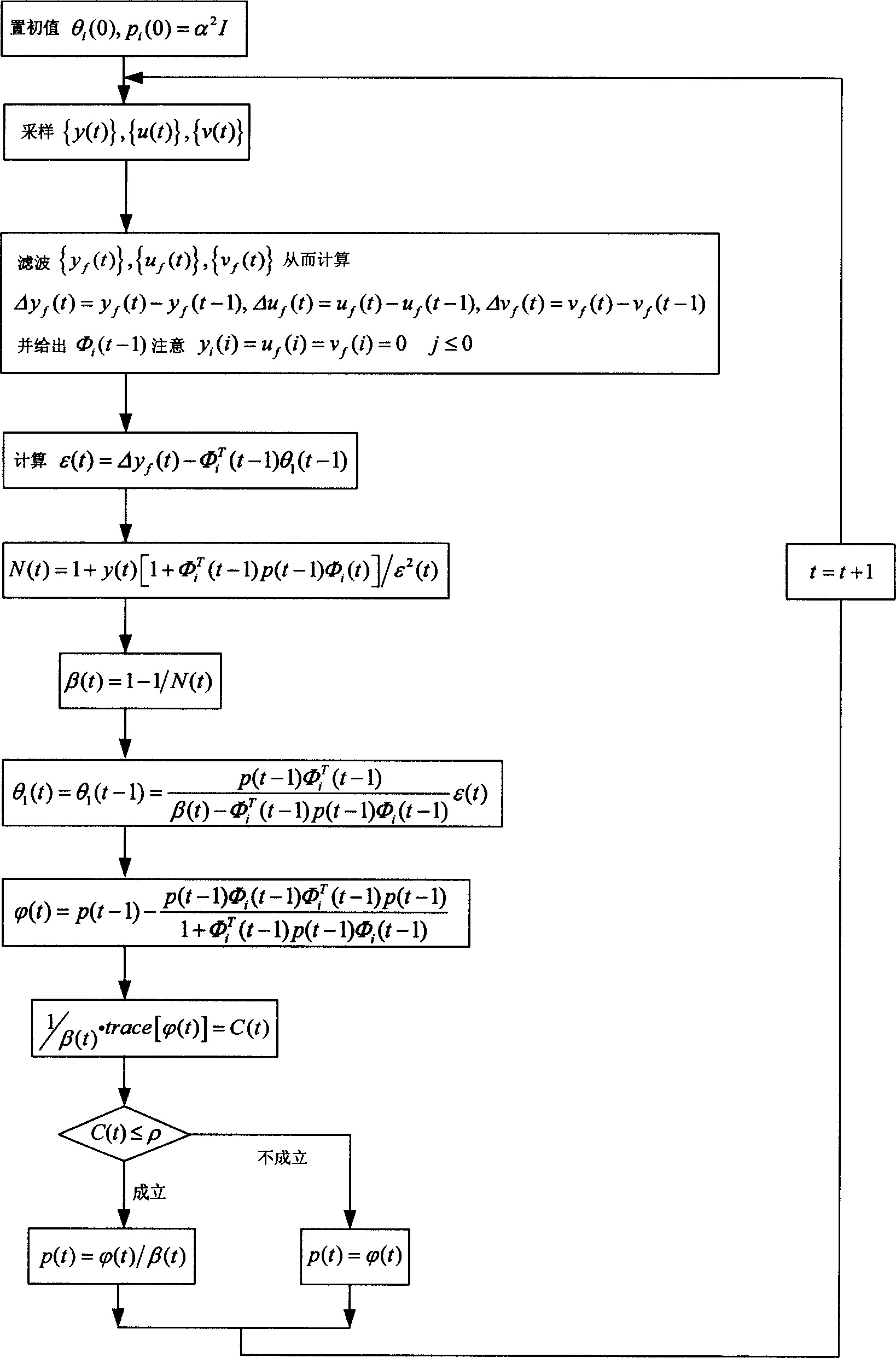

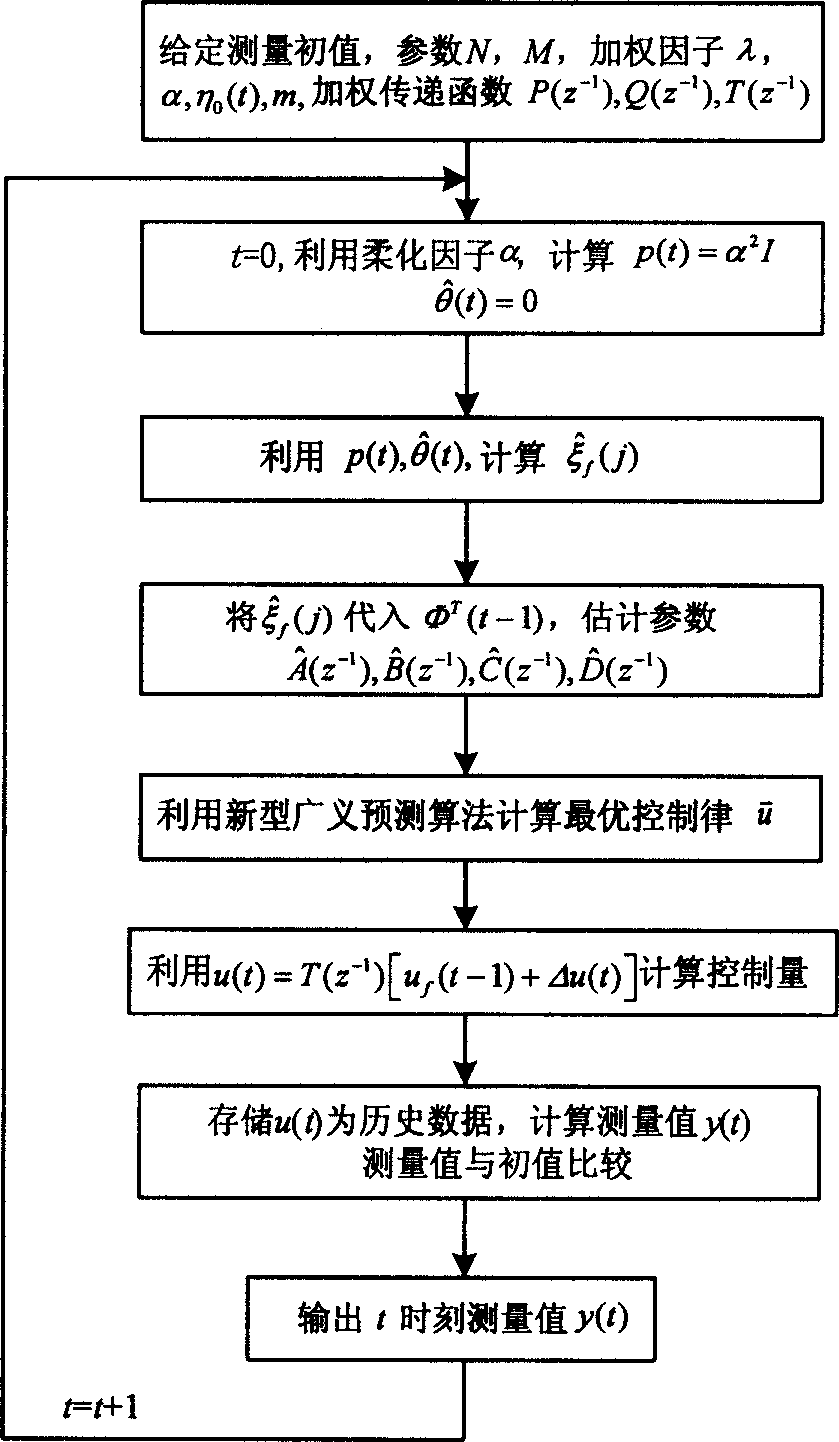

[0113] Embodiment: On-line measurement method of key parameters in boiler combustion process based on novel generalized predictive control.

[0114] 1. Establishment of the flue gas oxygen content measurement and control model

[0115]Keeping the best state and economy of boiler combustion process is an important task of automatic control of boiler combustion process. During boiler operation, the ratio between the amount of air entering the boiler and the amount of fuel must be well controlled. If the ratio of the amount of air to the amount of fuel is relatively small, the chemical incomplete combustion loss will be large, otherwise, the exhaust heat loss will increase. In order to keep the boiler in the best combustion condition, the ratio of the air volume to the combustion volume must be appropriate. This ratio is called the excess air coefficient, and the value should be between 1.20 and 1.30. There is a definite (single value) functional relationship between the oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com