Exhaust gas recirculation device for engine

一种引擎、排气阀的技术,应用在装料系统、废气再循环、燃料中加入非燃料物质等方向,能够解决成本高、EGR机构复杂构造等问题,达到减低NOX、抑制燃烧温度的上升、降低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

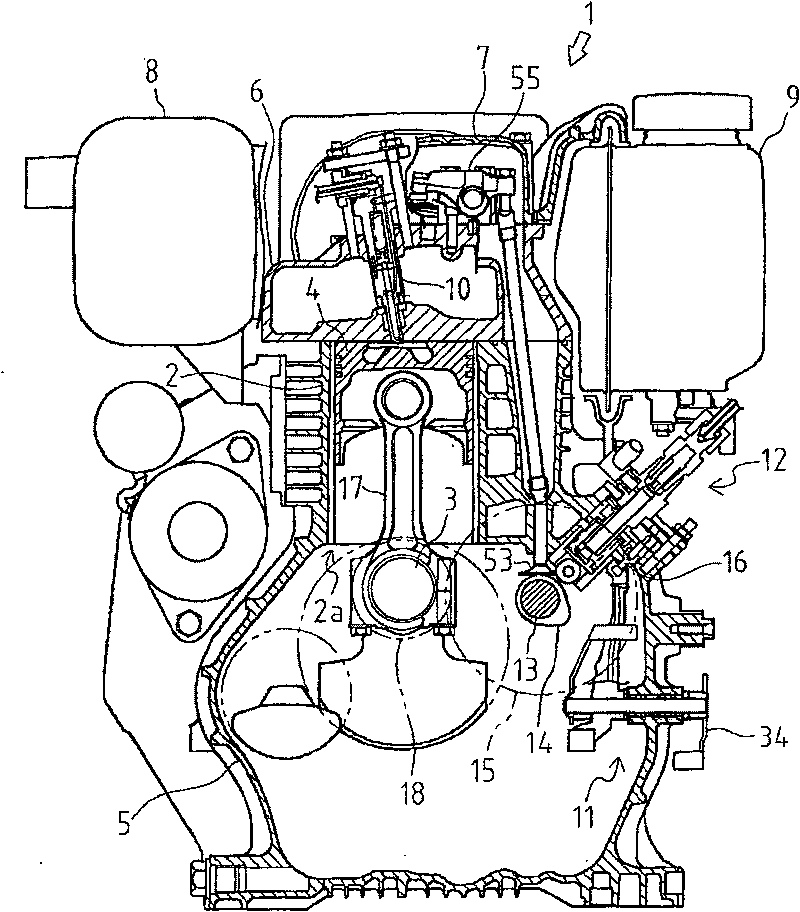

[0034] First, the overall structure of the engine of the present invention will be described.

[0035] As shown in Figure 1, the main body of the engine 1 is composed of an upper cylinder block 2 and a lower crankcase 5, and a cylinder block 2a is formed at the center of the cylinder block 2 facing up and down. Piston 4 is accommodated in 2a. A crankshaft 3 is pivotally supported in the front-rear direction on the crankcase 5 , and the crankshaft 3 and the piston 4 are connected via a connecting rod 17 .

[0036] A cylinder head 6 is arranged on the above-mentioned cylinder block 2, and an organic cover shell 7 is arranged on the cylinder head 6 to form a valve wrist chamber. A muffler 8 is disposed on one side of the cylinder head 6 at the top of the engine (the left side in the first figure), and a fuel tank 9 is disposed on the other side (the right side in the first figure).

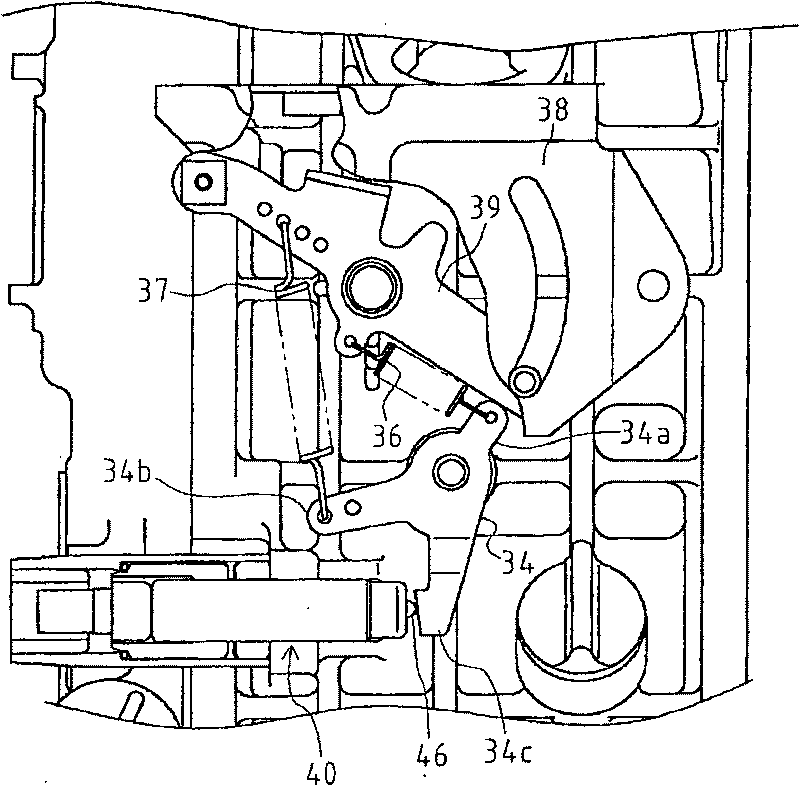

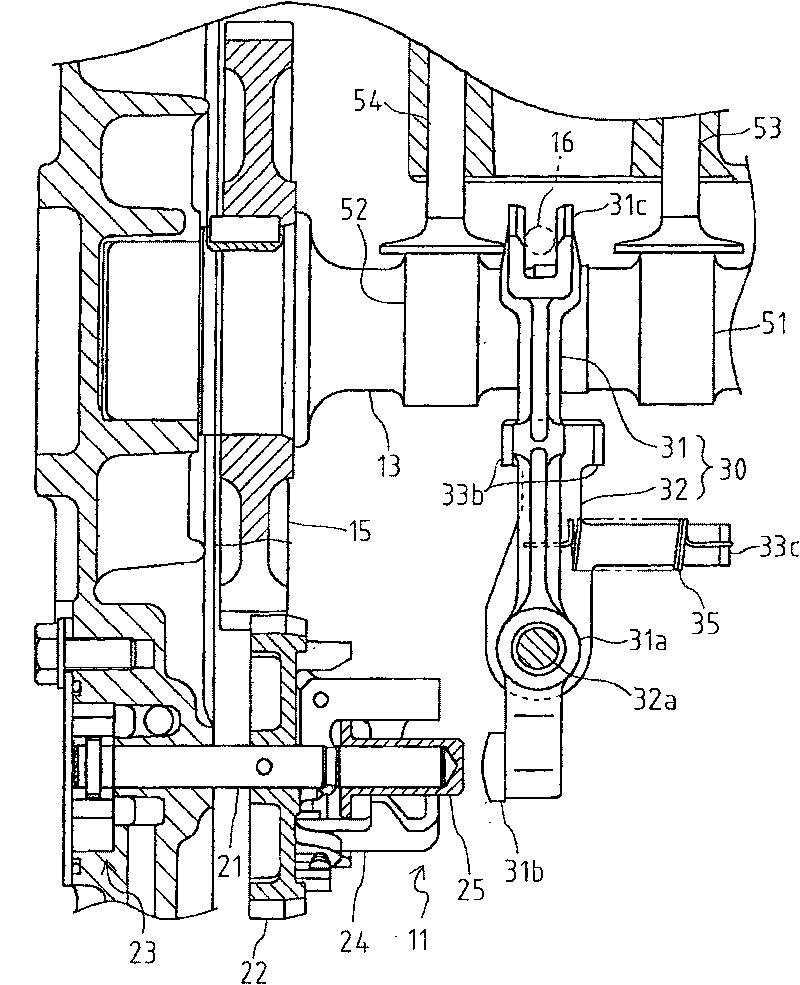

[0037] A balance weight, a governor device 11 and the like are arranged in the crankcase 5 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com