Solid immersion lens and microscope

An immersion lens and microscope technology, applied in microscopes, lenses, instruments, etc., can solve the problem of electronic device inspection requiring a lot of labor and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

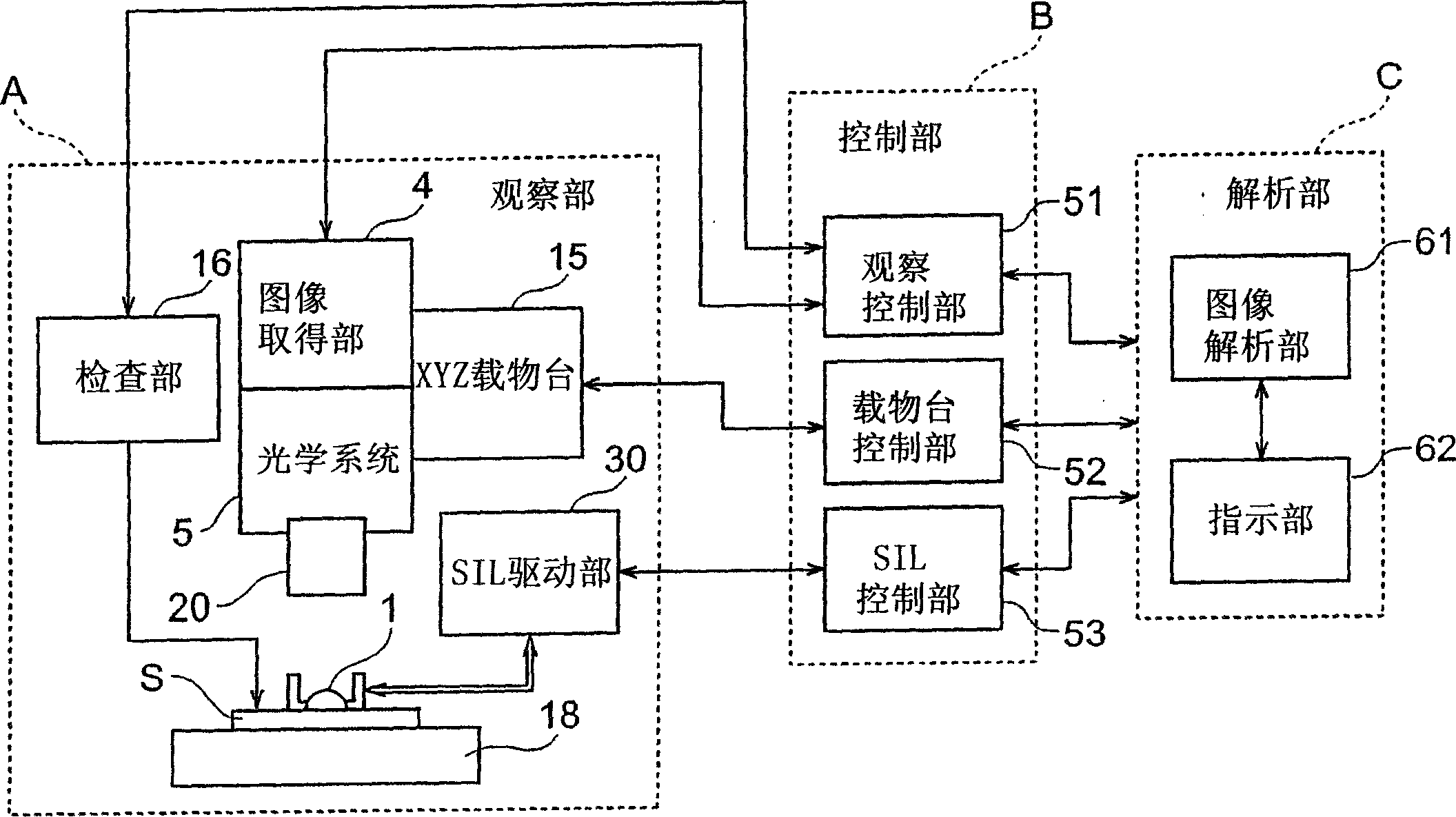

[0042] Preferred embodiments of the present invention will be described below with reference to the drawings. In addition, in each embodiment, the same code|symbol is attached|subjected to the part which has the same function, and overlapping description is abbreviate|omitted. In addition, the dimensional ratios of the drawings do not necessarily match those described.

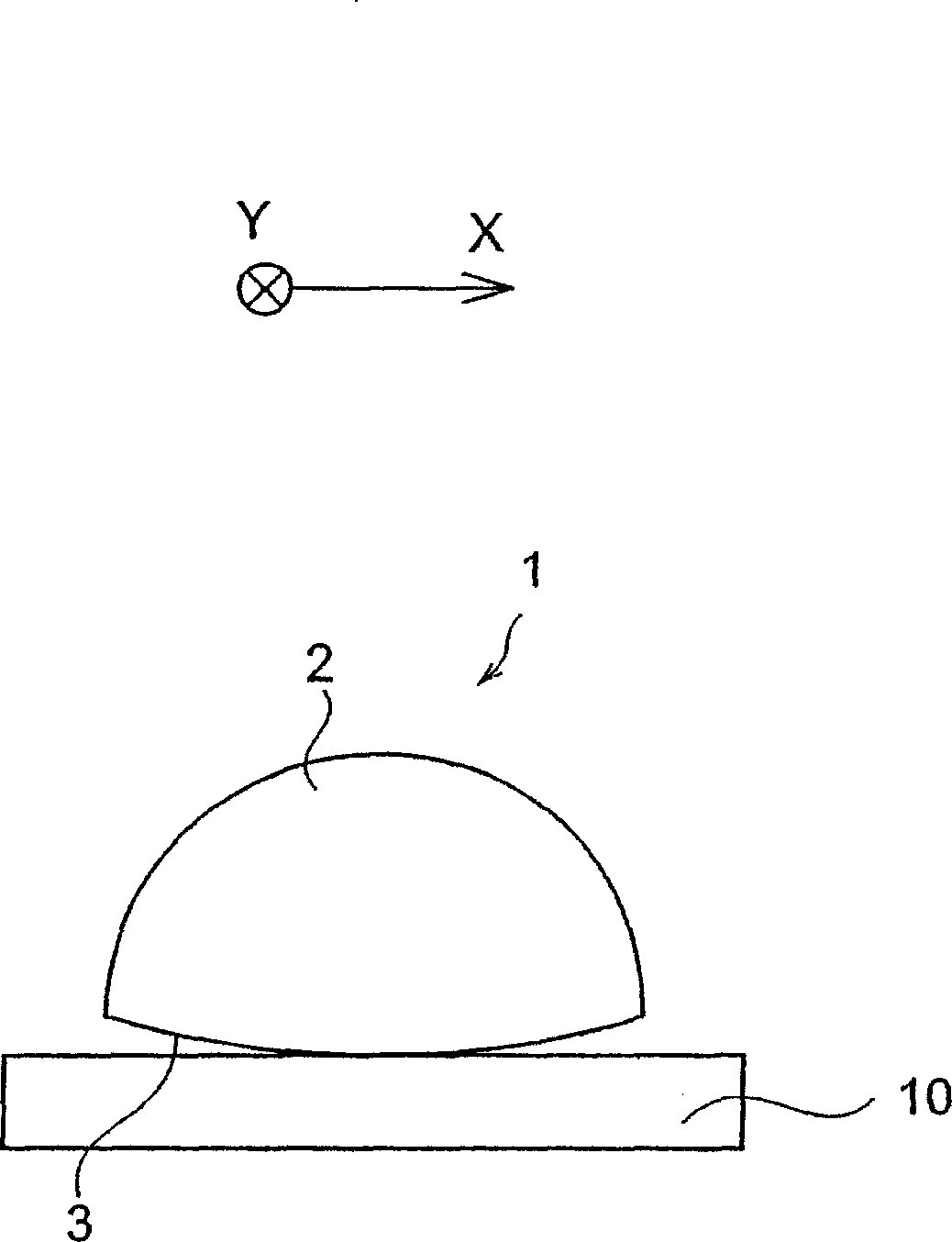

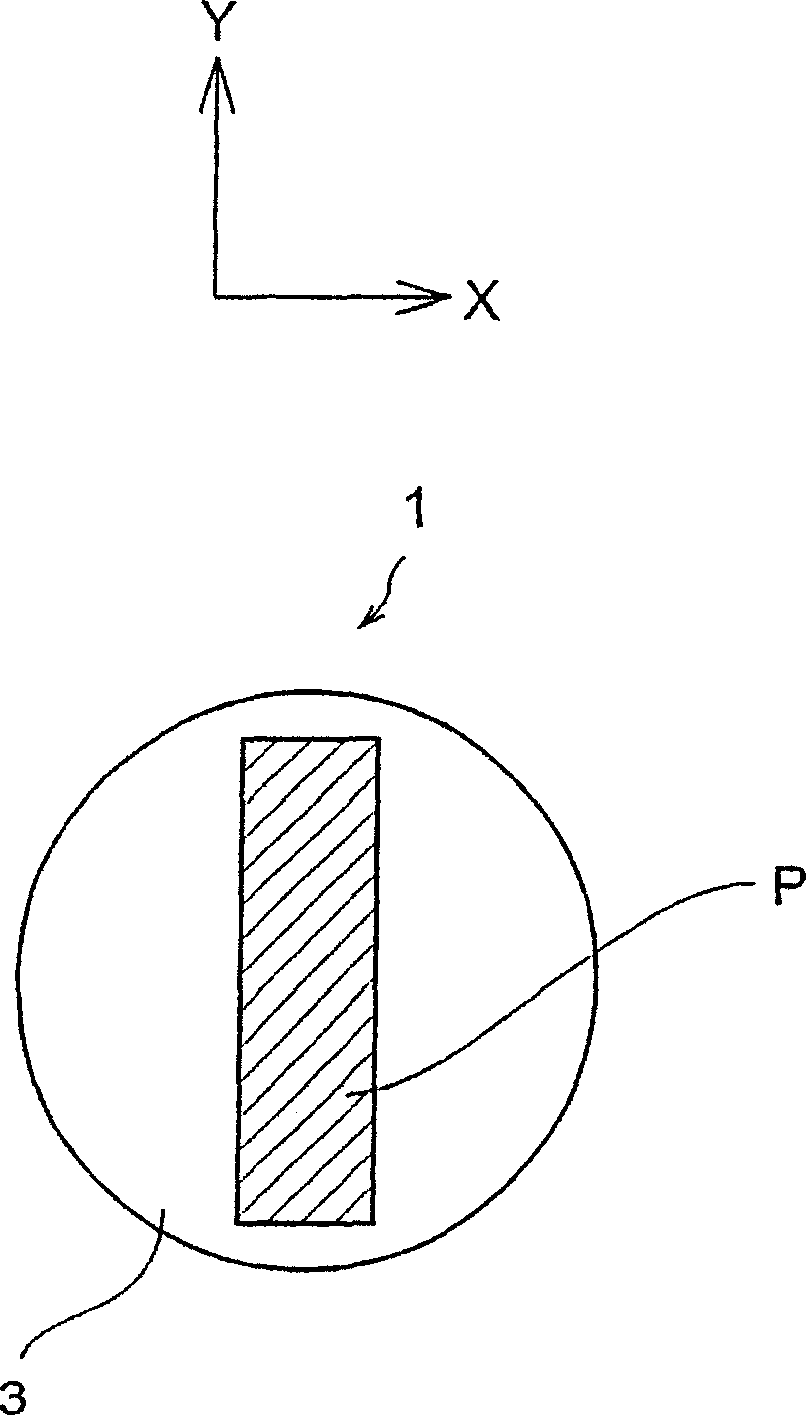

[0043] Figure 1A and Figure 1B It shows the state after mounting the immersion lens of this embodiment on a semiconductor substrate, Figure 1A is a side view, Figure 1B It is a rear view.

[0044] The immersion lens 1 of this embodiment is mounted on a substrate of a semiconductor device to be observed (inspected) during use. When analyzing the back surface of a semiconductor device using an immersion lens, the semiconductor substrate itself is utilized as a part of the immersion lens by optically coupling the immersion lens to the semiconductor substrate. In this way, when the focus of the objective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com