Welding power output control method

A welding power supply and output control technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of increasing the inductance value of welding power supply and unable to suppress the fluctuation state, so as to improve the fluctuation state, good welding quality, and stable The effect of welding state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

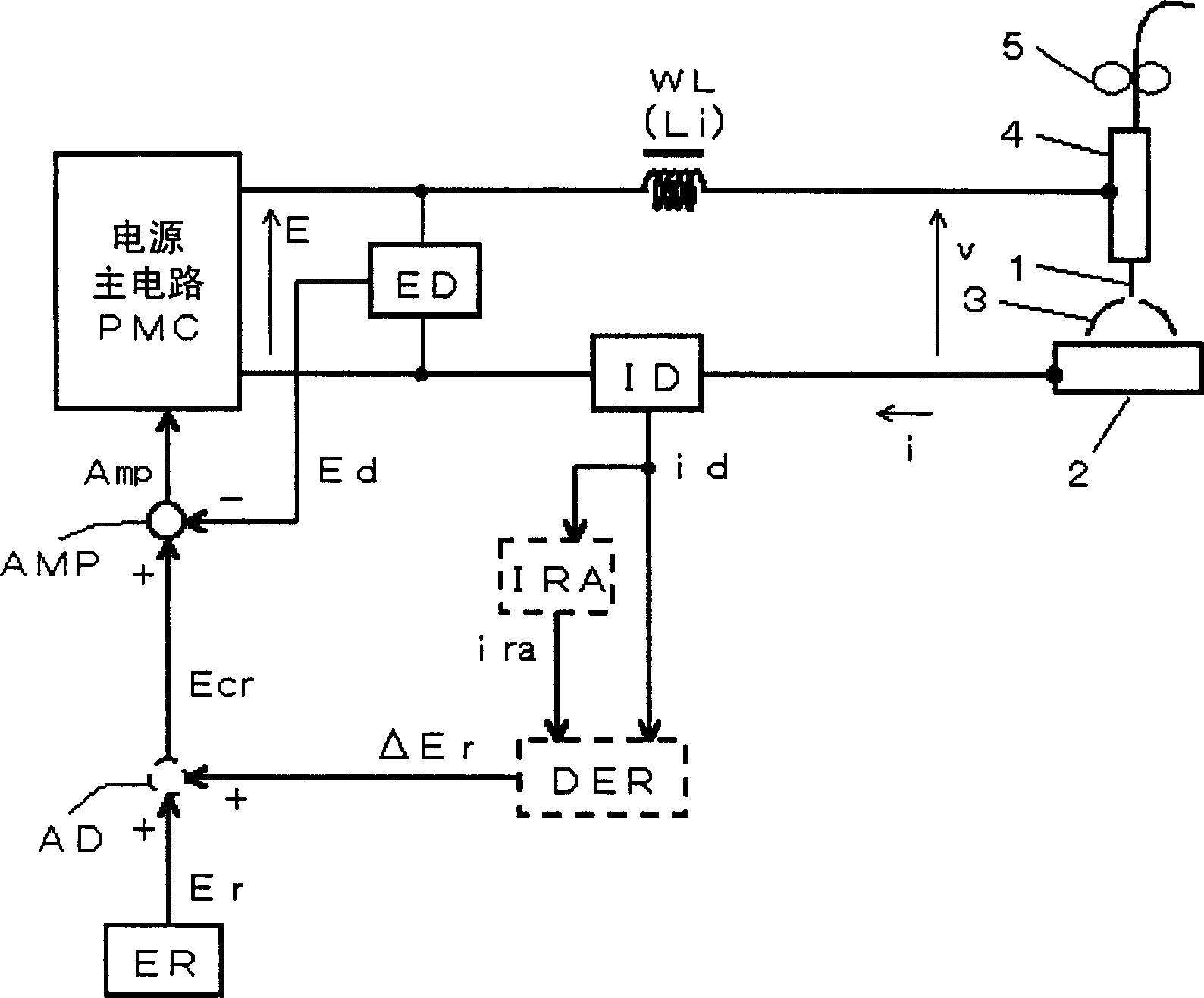

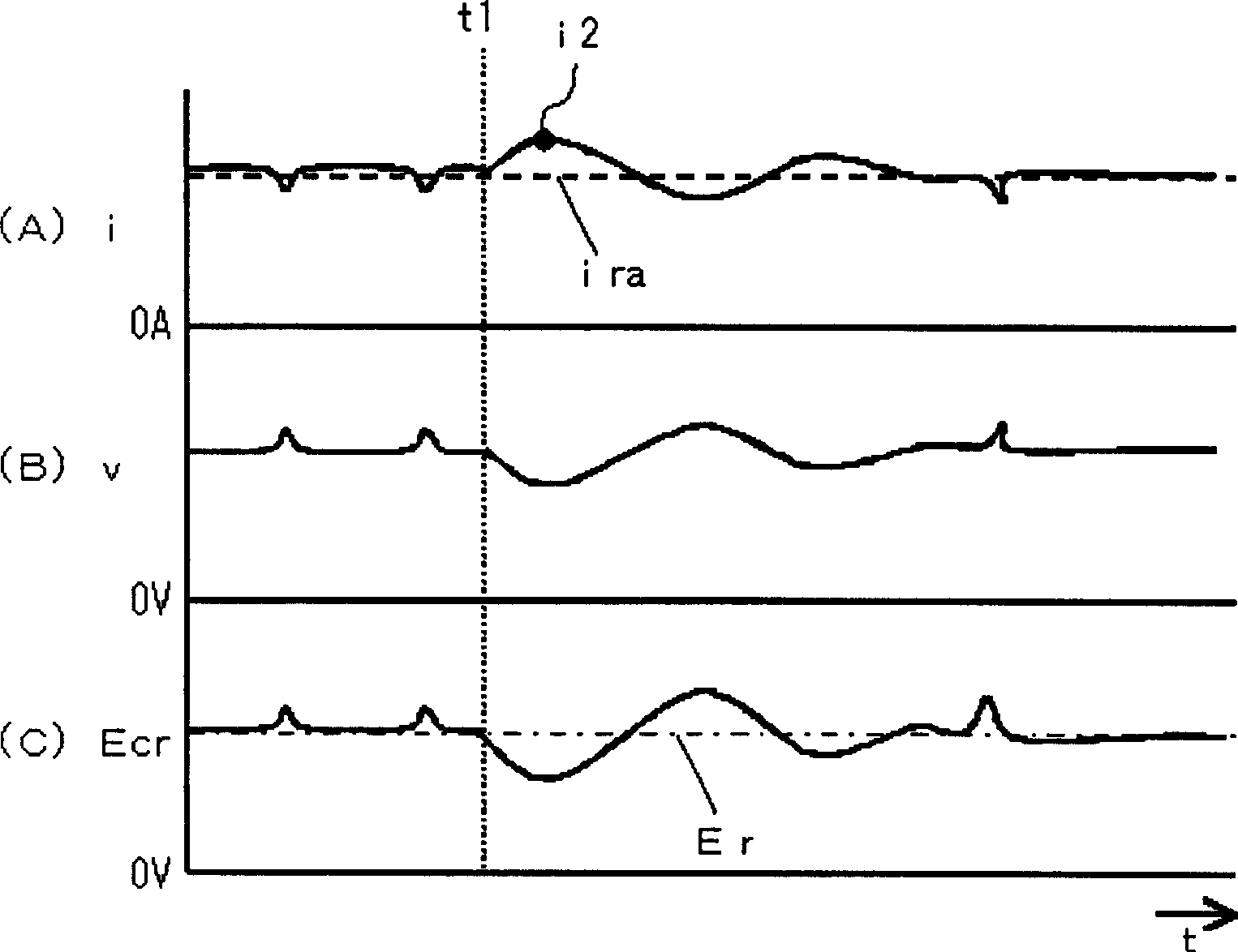

[0045] Embodiment 1 of the present invention performs a moving average on the welding current i, calculates the welding current moving average ira, and calculates the error amplification value ΔEr=Gain·(ira-i) between the welding current moving average ira and the welding current i The error amplification value ΔEr is added to the predetermined voltage setting value Er to calculate the voltage control setting value Ecr, and the output is controlled so that the voltage control setting value Ecr is approximately equal to the output voltage E of the welding power source. The above-mentioned gain (Gain) is a predetermined amplification factor. Hereinafter, it demonstrates in detail with reference to drawings.

[0046] figure 1 It is a block diagram of the welding power supply for implementing the output control method of the welding power supply according to the first embodiment. In this figure, with the above Figure 5 The same symbols are attached to the same blocks, and desc...

no. 2 Embodiment approach

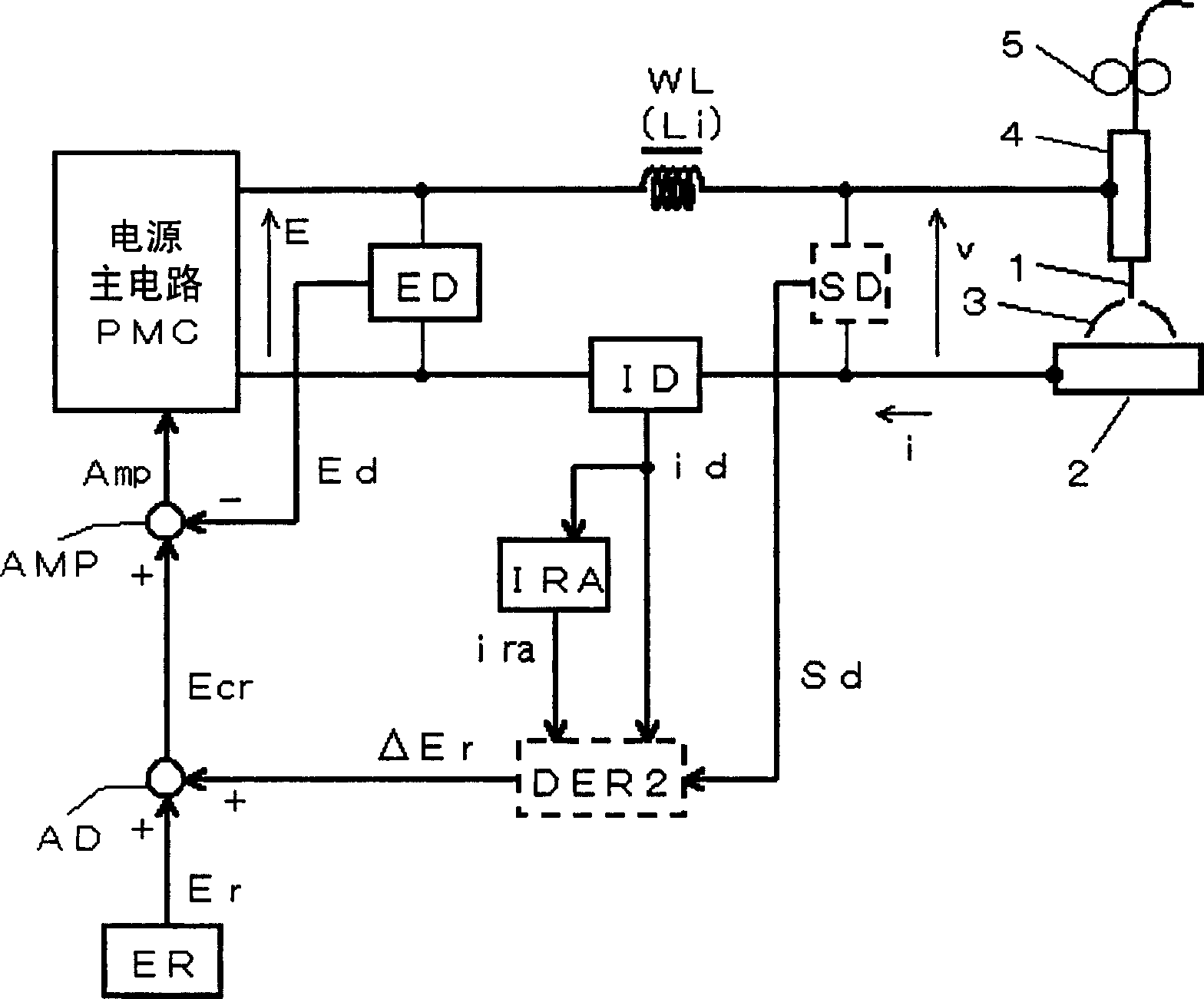

[0051] In Embodiment 2 of the present invention, in Embodiment 1, the voltage control setting value Ecr during the short-circuit period is set to a value equal to the voltage setting value Er, or to a value limited within a predetermined range by the voltage setting value Er. . As mentioned above, short circuits exceeding several ms rarely occur in globular transfer or spray transfer welding. During this short-circuit period, since the arc load changes to a short-circuit load, the welding current increases. At this time, if the present invention functions, an increase in welding current can be suppressed. However, during the welding period, increase the welding current, release the short circuit early, and stabilize the welding state on the arc regenerating side. Therefore, in Embodiment 2, the current change suppression control of the present invention is substantially prohibited during the short-circuit period. Hereinafter, it demonstrates in detail with reference to draw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap