Inkjet printer

A printer and inkjet technology, applied in the direction of winding strips, sending objects, thin material processing, etc., to achieve the effect of shortening the time required for the process, shortening the time of the process, and shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Hereinafter, embodiments of the present invention will be described based on the drawings.

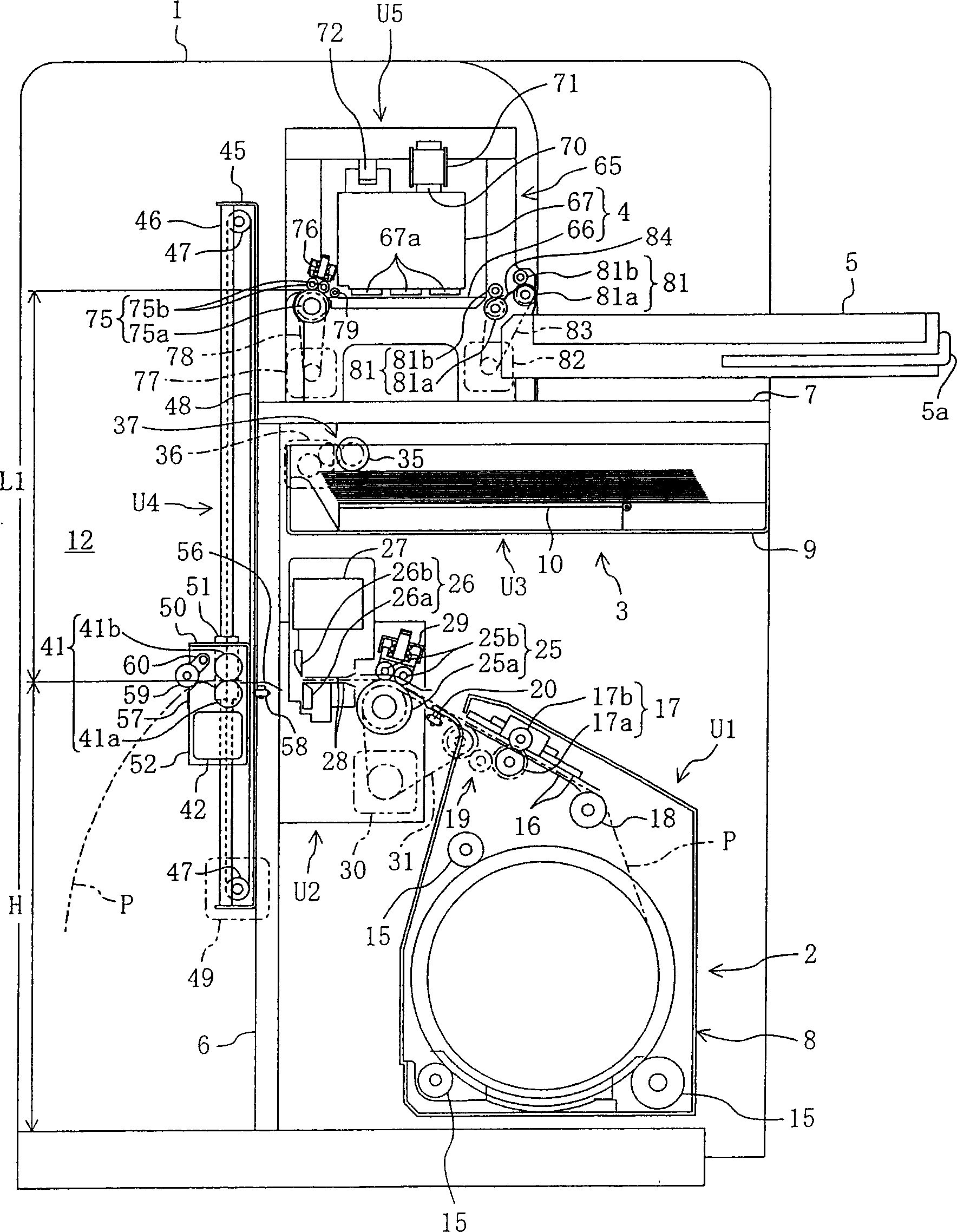

[0073] figure 1 An inkjet printer according to an embodiment of the present invention is shown. This inkjet printer is used in a photo printing system, and is connected to a receiving block 100 (refer to Figure 8 ) connection, the image data transmitted from the receiving block 100 through the communication cable is printed on the printing paper P based on the command information.

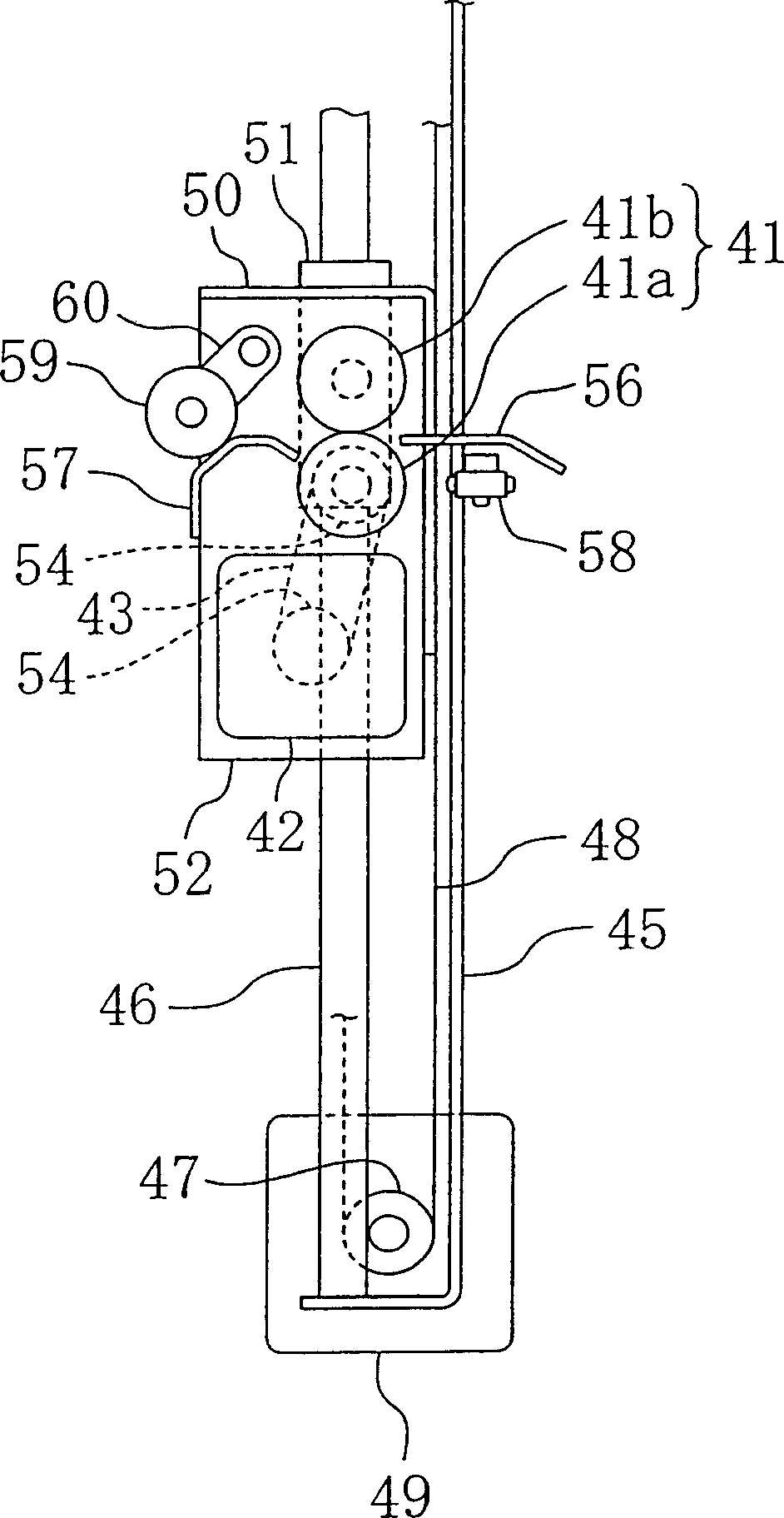

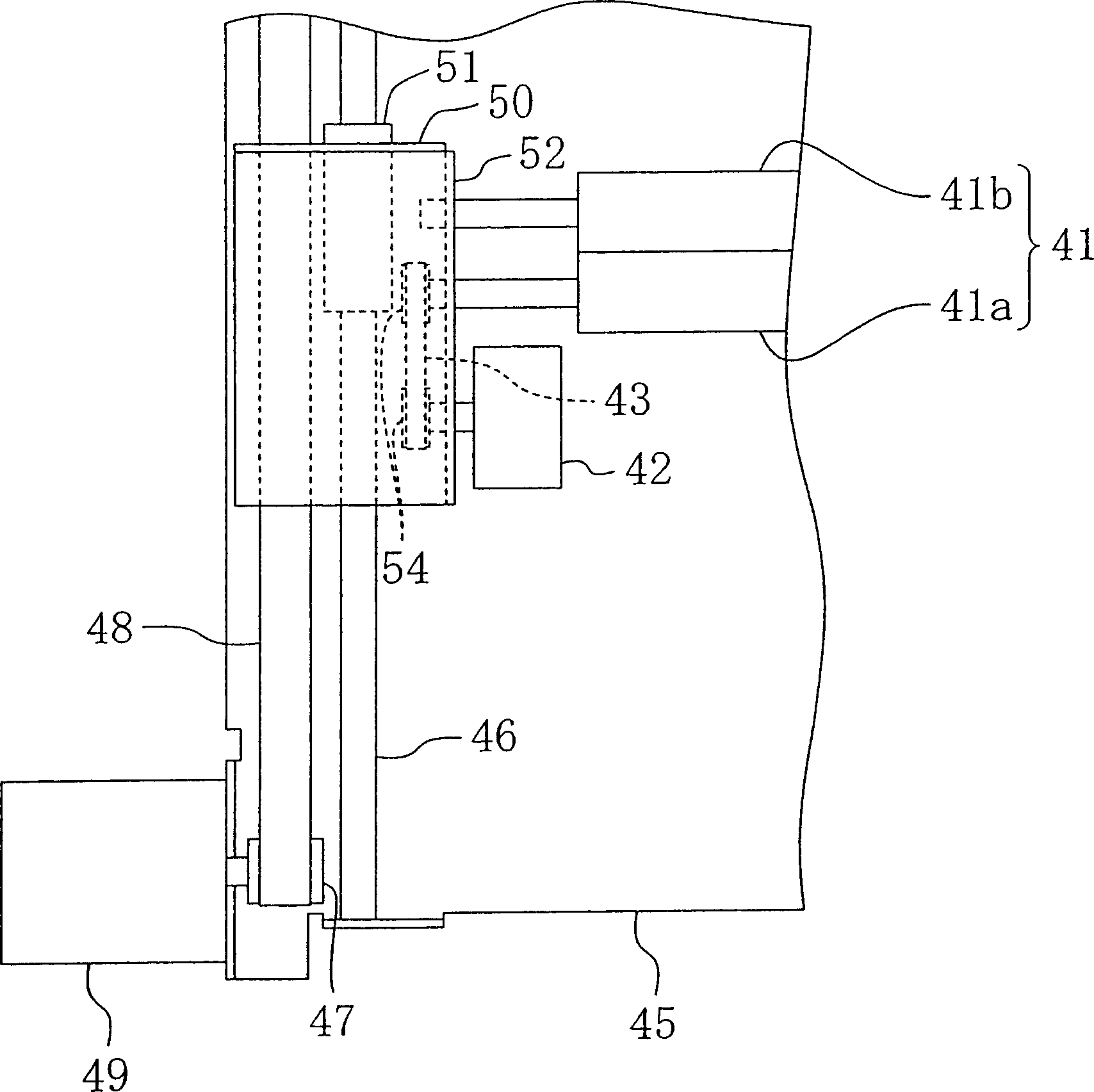

[0074]The above-mentioned inkjet printer has: a frame body 1; a carton accommodating portion 2 disposed at the lower portion of the frame body 1; a box accommodating portion 3 disposed approximately in the vertical direction inside the frame body 1; 1, and the printing section 4 that prints the image data on the printing paper P; the first transport path for transporting the printing paper P from the carton storage section 2 to the printing section 4; The second conveying path for conveying the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com