Backlight assembly and its lamp activating method

A technology for backlight components and lamps, applied in optics, discharge lamps, electrical components, etc., can solve problems such as transformer burnout, inability to light all lamps at the same time, and reduced product reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

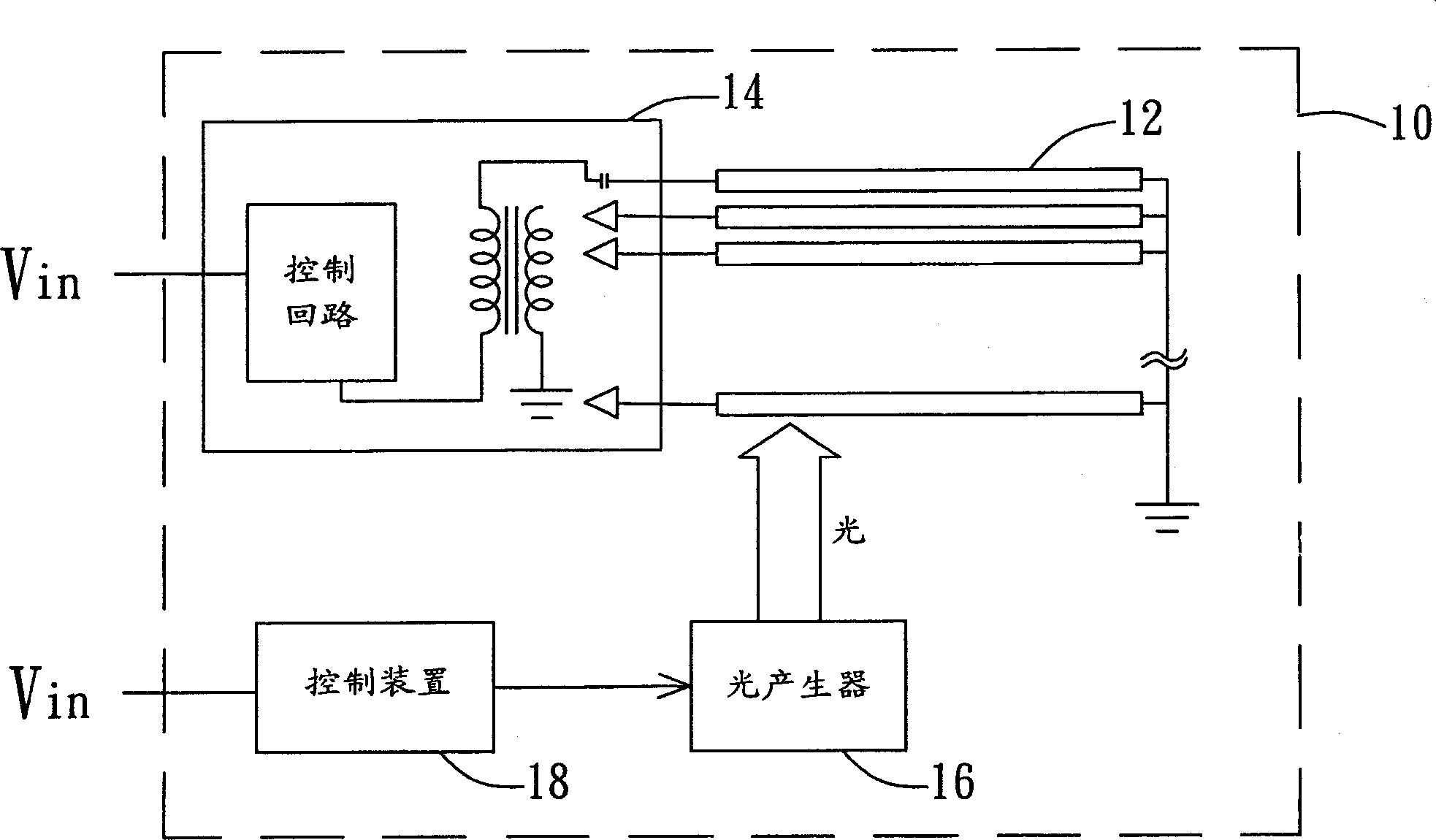

[0015] Please refer to figure 1 , which is a schematic diagram of the backlight assembly of the present invention. A backlight module 10 disclosed in a preferred embodiment of the present invention includes at least one light tube 12 , a regulating component 14 and a light generator 16 . The plurality of lamps 12 are cold cathode fluorescent lamps (Cold Cathode Fluorescent Lamp, CCFL), arranged in parallel, and electrically connected with the regulating component 14 . The regulating component 14 includes a transformer and a control circuit. The transformer can convert a voltage from an external power source and output an activation voltage to the lamp 12. The control circuit is electrically connected to the transformer to control the voltage output by the transformer. In this way, the externally input voltage, such as a commercial power (AC), can be converted by the control component 14 to output a usable voltage for the lamp tube 12 , such as a direct current (DC).

[0016]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com