Machine room-less elevator

A technology of machine room-less elevators and elevator shafts, which is applied to elevators, hoists, transportation and packaging in buildings to achieve the effect of improving space efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

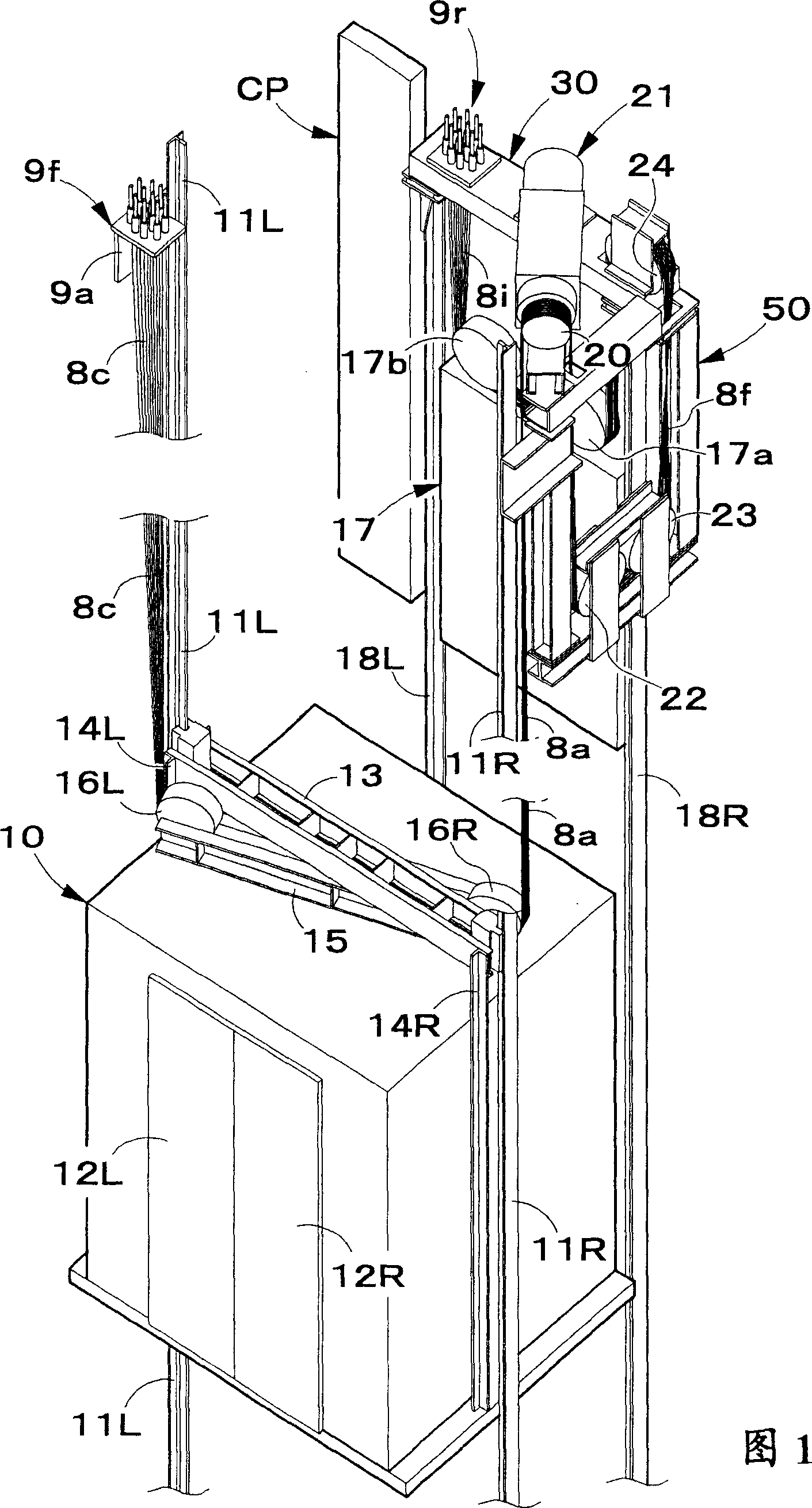

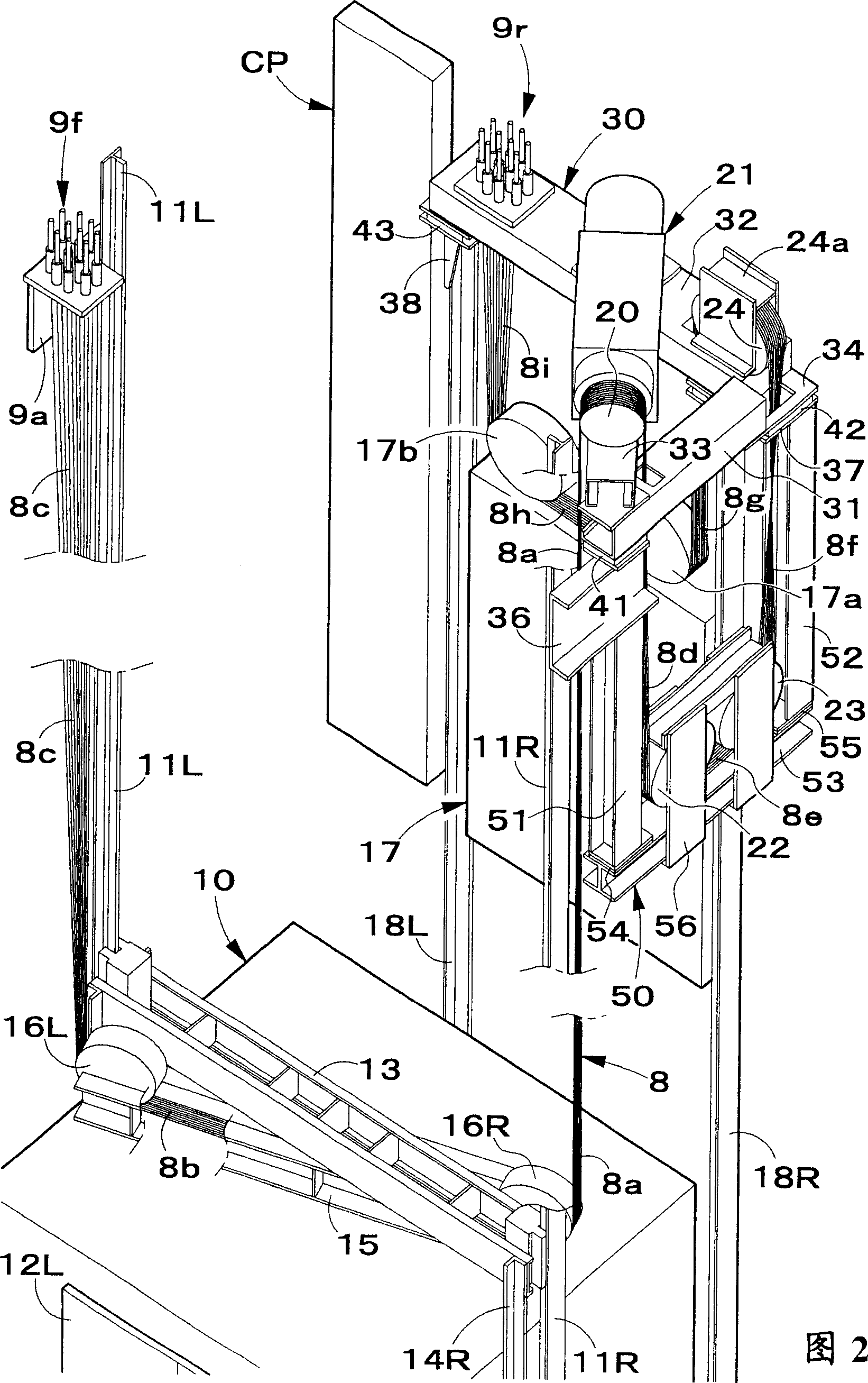

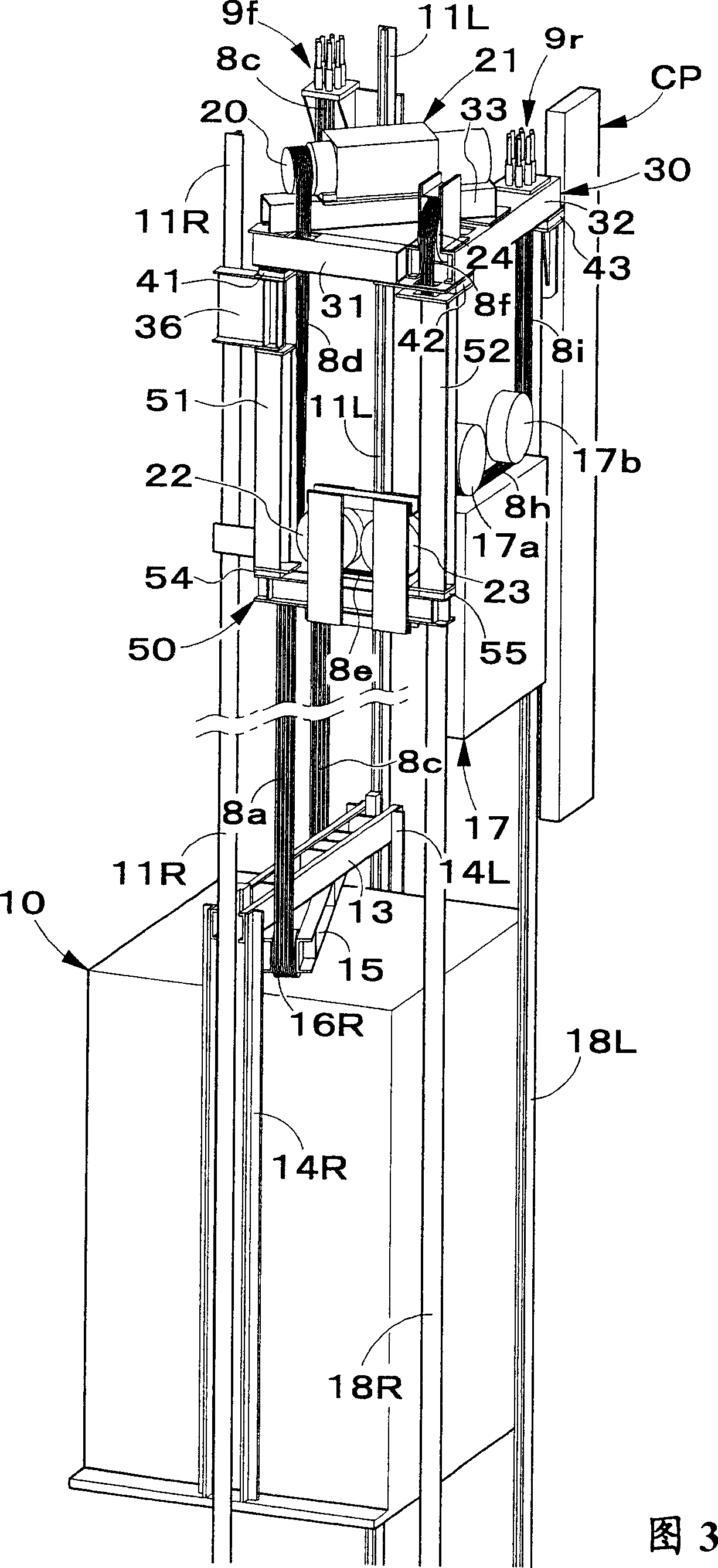

[0050] Next, a machine room-less elevator system according to a preferred embodiment of the present invention will be described with reference to FIGS. 1-5. In the following description, the direction in which the car door moves is called the horizontal direction, the direction in which passengers walk out of the car is called the forward direction, the direction in which passengers enter the car is called the backward direction, and the direction in which the elevator car moves is called the for the vertical direction. and Image 6 Corresponding parts of the hoisting member of the machine-room-less elevator system shown in FIG. 1 are indicated by the same reference numerals.

[0051] The machine room-less elevator system according to the preferred embodiment of the present invention shown in FIGS. 1-5 has a car 10 guided by a right car guide rail 11R and a left car guide rail 11L in an elevator shaft formed in a building. Move vertically in S. The right door 12R and the lef...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap