Contractible safety self-ruined syringe

A syringe and self-destruct technology, applied in the field of medical devices, can solve problems such as failure to use normally, low production yield, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

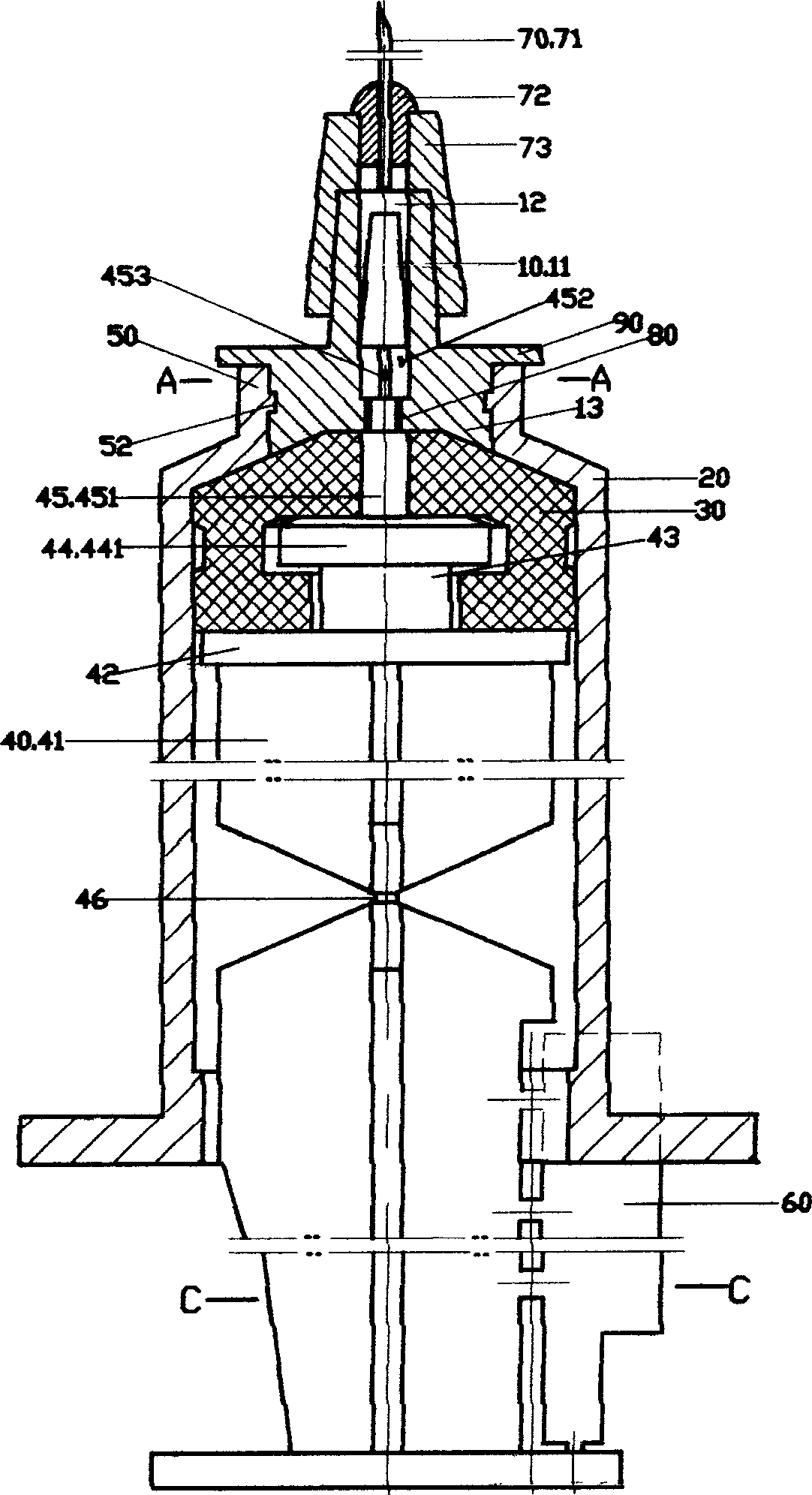

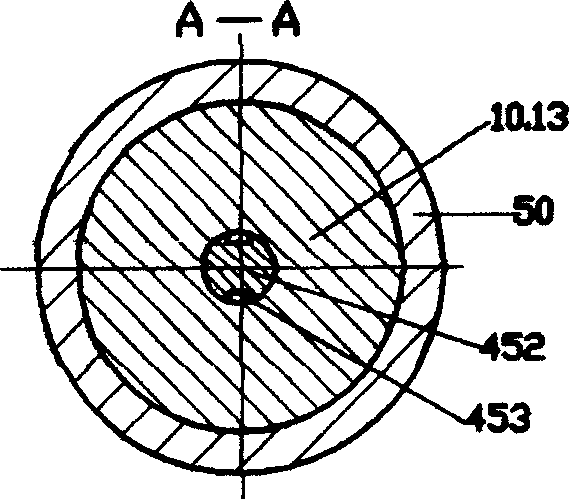

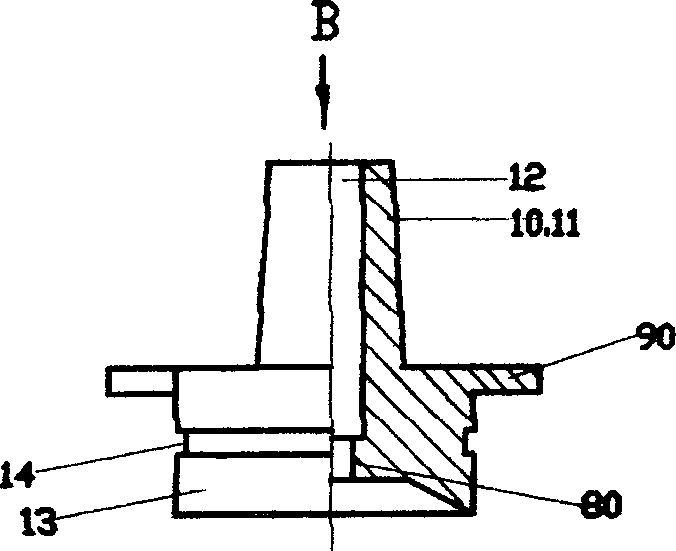

[0044] See figure 1 Referring to Fig. 8, the materials used in the syringe of this embodiment meet the national standard. The syringe of this embodiment comprises a jacket 20, a piston 30 and a core rod 40; the core rod 40 is an integral part with a shaft 41, a top 42, a neck 43 and a head 44; the piston 30 is sleeved on the head of the core rod 40 44, the syringe also has a retractable part 10, the retractable part 10 is an integral part with a cone head 11 and a positioning part 13, the positioning part 13 is arranged on the lower part of the retractable part 10, and the retractable part 10 has an axial through hole 12 The upper part of the overcoat 20 is provided with an airtight positioning part 50, the overcoat 20 and the airtight positioning part 50 are integrated, and the airtight positioning part 50 has a through hole 51; 51, the outer wall of the positioning part 13 of the retractable part 10 can be airtightly fitted with the inner wall of the through hole 51 of the ...

Embodiment 2

[0048] 9 to 12, the syringe of this embodiment is provided with a stopper 90 on the outer wall of the positioning part 13 of the retractable part 10; the stopper 90 is in the shape of a boss; the number of stoppers 90 in the shape of a boss It is one; in this embodiment, the size of the force that causes the retractable component 10 to disengage and shrink can be designed to be 35 Newtons, and the size of the outer diameter of the boss-shaped stopper 90 can be designed to be 35 Newtons. When the pulling force occurs, it will be disengaged and shrink; it can ensure the normal assembly of the syringe, and it can absorb and inject the liquid medicine normally during use; a sealing groove 53 is provided on the inner wall of the through hole 51 of the airtight positioning part 50 of the overcoat 20, so that The outer wall of the positioning portion 13 of the shrinkable component 10 is provided with a sealing boss 15, and the inner diameter of the sealing groove 53 on the inner wall ...

Embodiment 3

[0050] See Figure 13 to Figure 15 , the syringe of this embodiment is provided with an O-ring seal 131 on the outer wall of the positioning portion 13 of the retractable component 10; 131 is sleeved and fixed in the sealing groove 14 on the outer wall of the positioning portion 13 of the shrinkable part 10; a sealing groove 53 is provided on the inner wall of the through hole 51 of the airtight positioning portion 50 of the outer casing 20, and the O-ring seal The outer diameter of 131 is 0.25mm larger than the inner diameter of the sealing groove 53 on the inner wall of the through hole 51 of the airtight positioning part 50 of the outer casing 20, so as to achieve the purpose of strengthening the sealing effect and ensuring that the syringe can absorb and inject the liquid medicine normally. This embodiment is suitable for syringes with specifications below 20 milliliters. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com