Special-shaped seal ring of injector

A special-shaped sealing ring and syringe technology, applied in the field of medical devices, can solve the problems of difficult to meet the standard, low production yield, high cost, etc., and achieve the effects of good effect, reduced resistance and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

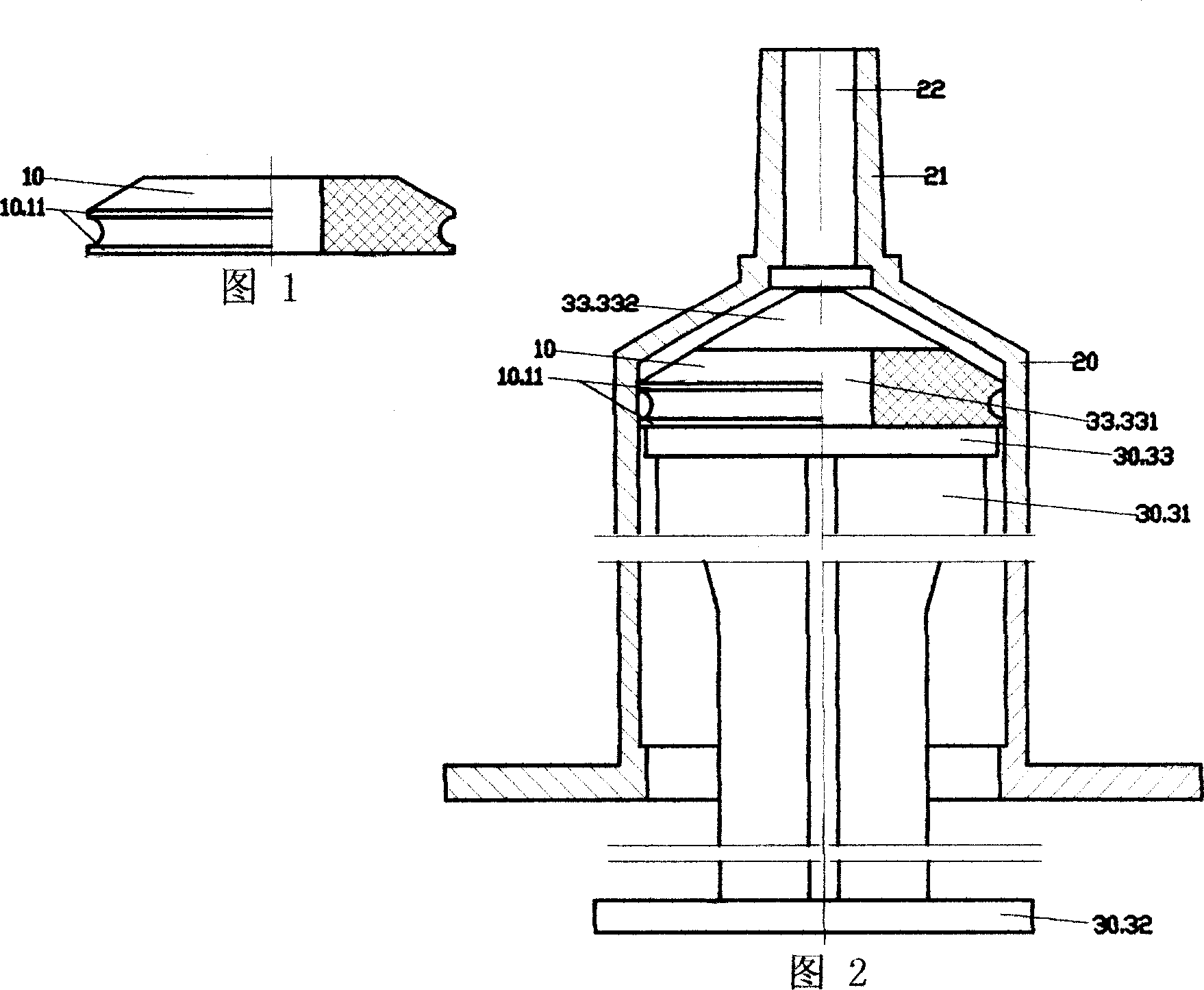

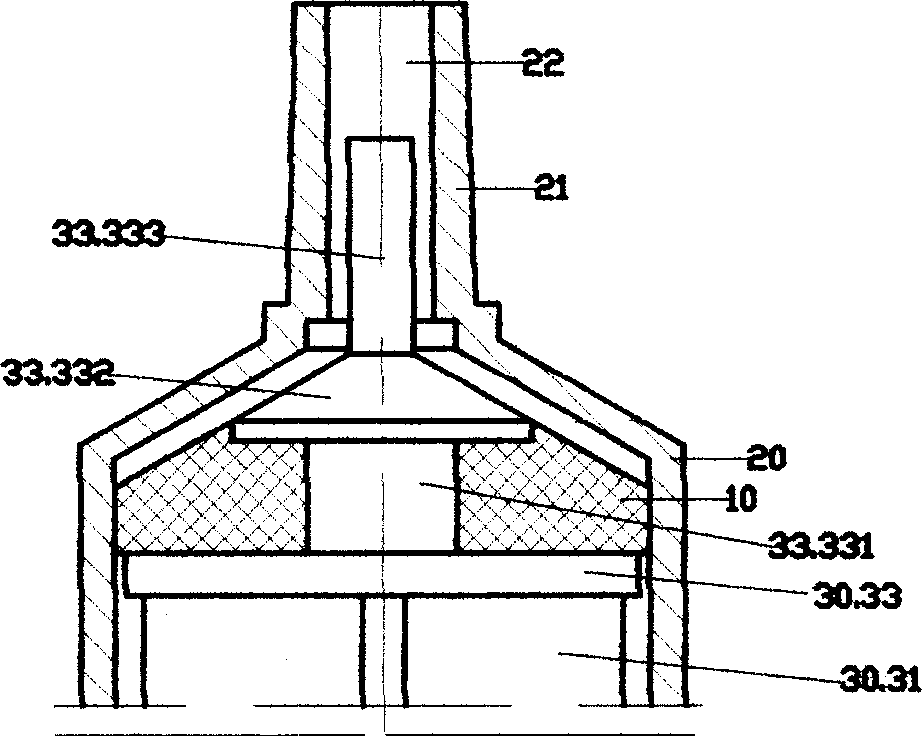

[0037] Referring to Fig. 1 to Fig. 2, the material used for the special-shaped sealing ring of the syringe in this embodiment complies with the national standard. See Fig. 1, the shape of the cross section of this special-shaped sealing ring 10 of the present embodiment is bow-knot shape; The outer wall of this special-shaped sealing ring 10 having the cross-sectional shape is bow-knot-shaped is provided with elastic skirt 11; Elastic skirt 11 The number is two; the material used in the special-shaped sealing ring 10 is medical rubber that meets the national standard, which can achieve a remarkable sealing effect. In other embodiments, the materials that can be used in the special-shaped sealing ring 10 are natural rubber, medical soft polymer Vinyl chloride, low-pressure polyethylene, polytetrafluoroethylene; at the same time, because the contact surface between the special-shaped sealing ring 10 and the liquid medicine is very small, the pH value required by the national stan...

Embodiment 2

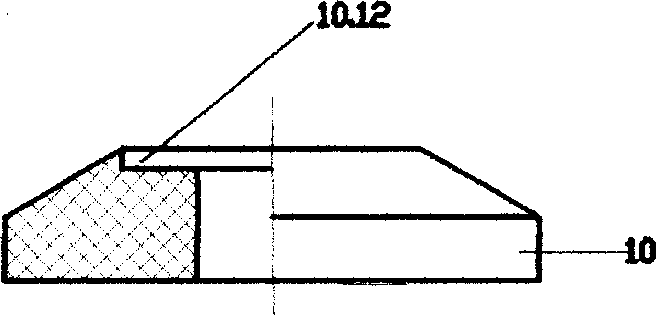

[0039] See Figure 3 to Figure 4 The shape of the cross section of the special-shaped sealing ring 10 of the syringe of the present embodiment is a bow-tie shape; the upper end of the special-shaped sealing ring 10 whose cross-sectional shape is a bow-tie shape is provided with a closed step 12, and the closed step of the special-shaped sealing ring 10 The inner diameter of the inner wall of 12 is less than 0.35 mm of the outer diameter of the head 332 of the top 33 of the core rod 30 to ensure that the syringe can normally absorb and inject the liquid medicine; the outer wall of the special-shaped sealing ring 10 in this embodiment does not have an elastic skirt 11. A protruding rod 333 is also provided on the head 332 of the top 33 of the core rod 30. The outer diameter of the protruding rod 333 is smaller than the inner diameter of the taper hole 22 of the syringe, so as to reduce the residual flow of the liquid medicine. All the other are identical with embodiment 1.

Embodiment 3

[0041] See Fig. 5 to Fig. 6, the shape of the cross section of this special-shaped sealing ring 10 of the present embodiment syringe is oval; See Fig. 5, this syringe also has injection needle 50, and injection needle 50 has needle tube 51, connecting portion 52 and needle Seat 53, the needle seat 53 of the injection needle 50 is hot-melted or bonded and fixed on the cone head 10; a breakable structure 40 is provided on the shaft 31 of the core rod 30; as shown in Figure 5, when the core rod 30 is pushed to the end, the medicine After the liquid injection is completed, after pulling the core rod 30 back about halfway, the breakable structure 40 on the shaft 31 of the core rod 30 can be exposed to the outside of the jacket 20, and the rod of the core rod 30 can be easily broken by using the principle of leverage. body 31, so that the syringe cannot be reused; a neck 331 and a head 332 are also provided on the top 33 of the core rod 30; When injecting, push the special-shaped se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com