Angular velocity detector having inertial mass oscillating in rotational direction

A technology of inertial mass and mass block, applied in gyro effect for speed measurement, speed/acceleration/shock measurement, steering sensing equipment, etc., can solve the problem that it is difficult to make the drive beam 40 with precise dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

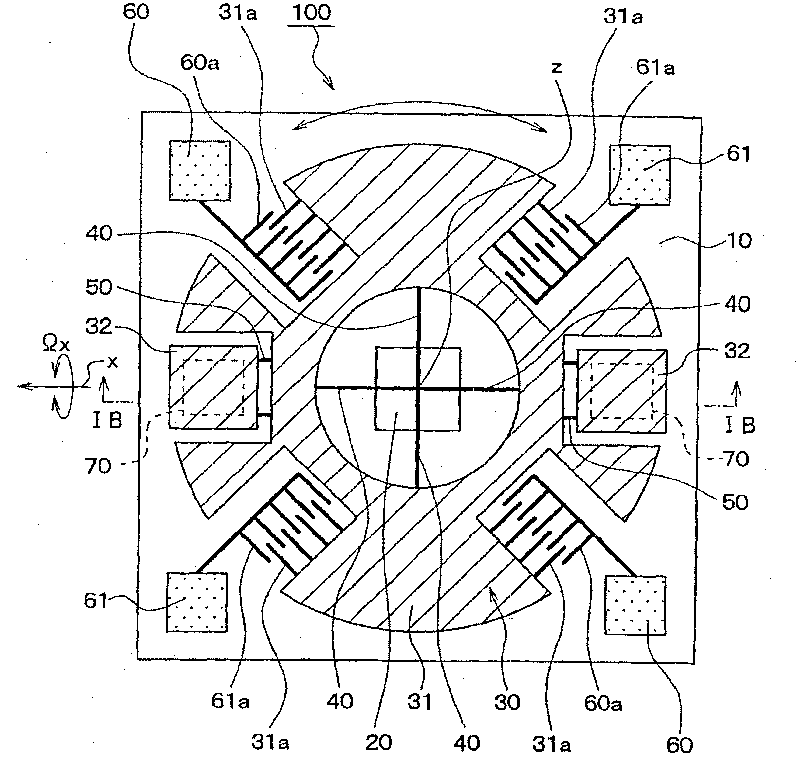

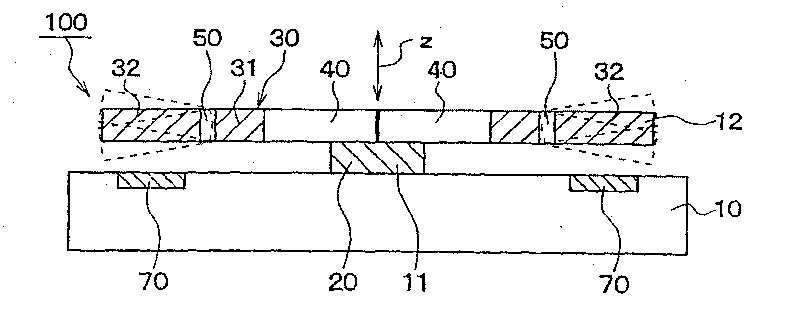

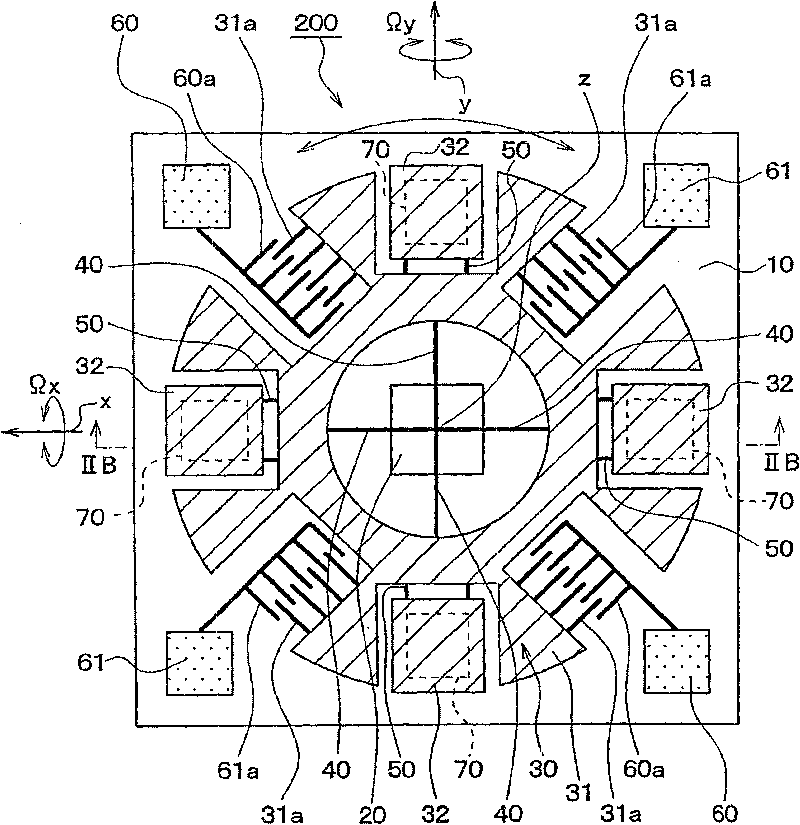

[0021] The first embodiment of the present invention is as Figure 1A with 1B As shown, the top view and cross-sectional view of the angular velocity detector 100 of the present invention are respectively shown. Figure 1A The crosshatching lines in do not refer to the cross section but represent the top surface of each component. In order to clearly distinguish the inertial mass 30 from the drive electrodes 60 , 61 , the former is marked with hatching, and the latter is represented with dots.

[0022] The angular velocity detector 100 is made of a three-layer board, which consists of a substrate 10, a sacrificial layer 11 (such as a silicon dioxide layer) and a semiconductor layer 12 (such as an epitaxial polysilicon layer (epitaxial poly-silicon layer)). The above layers are stacked in this order. Detector 100 is fabricated by known semiconductor processing techniques. Part of the sacrificial layer 11 is removed by etching to separate the inertial mass 30 from the base bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com