Improved parallel all colour organic electroluminescence display apparatus and mfg. method thereof

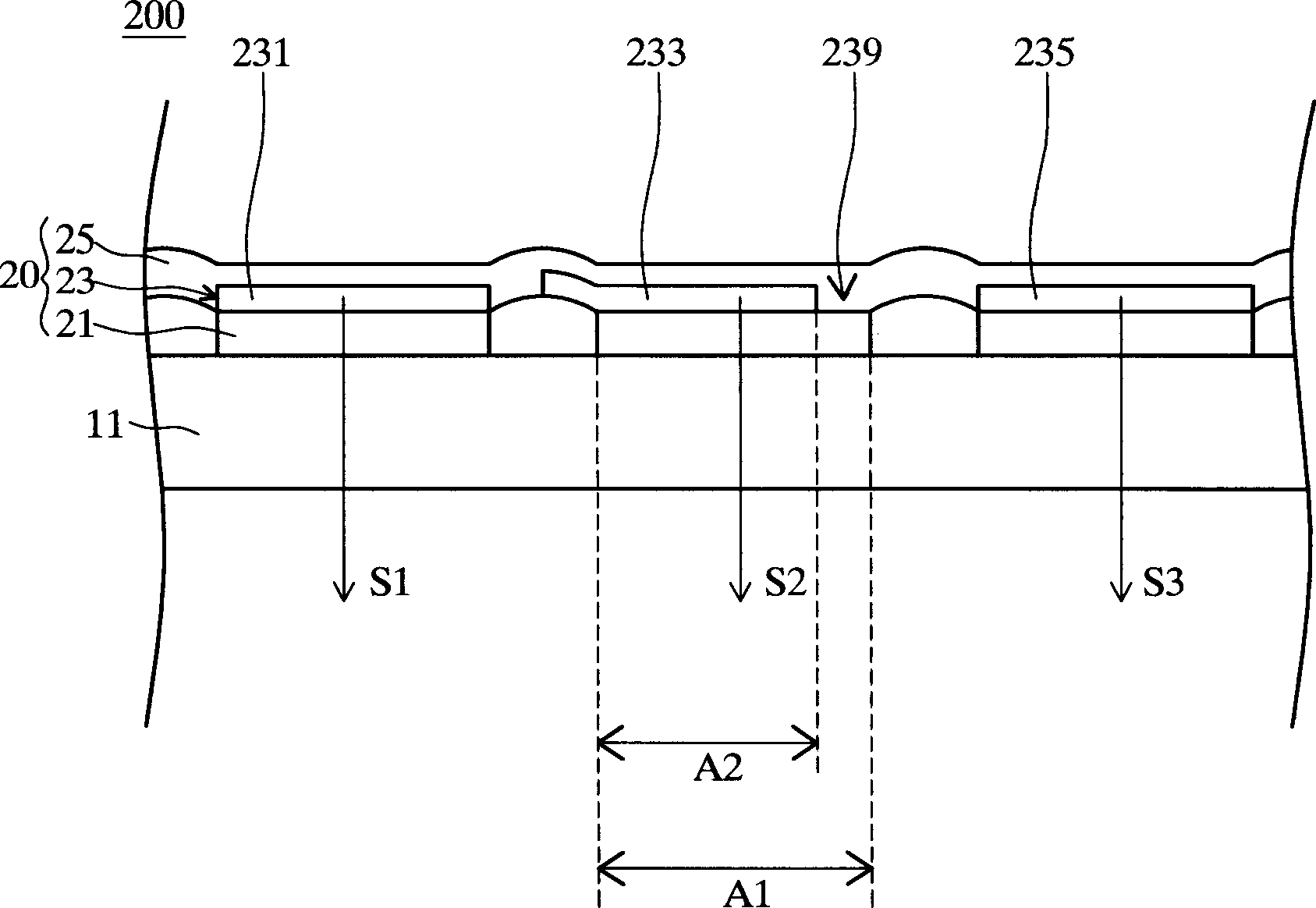

A display device and electroluminescence technology, applied in electroluminescence light sources, electric light sources, lighting devices, etc., can solve the problem of inaccurate shielding and alignment procedures, deviation of the setting position of the second organic light-emitting unit 233, and affecting the second light source S2. Problems such as the display quality of luminous brightness display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

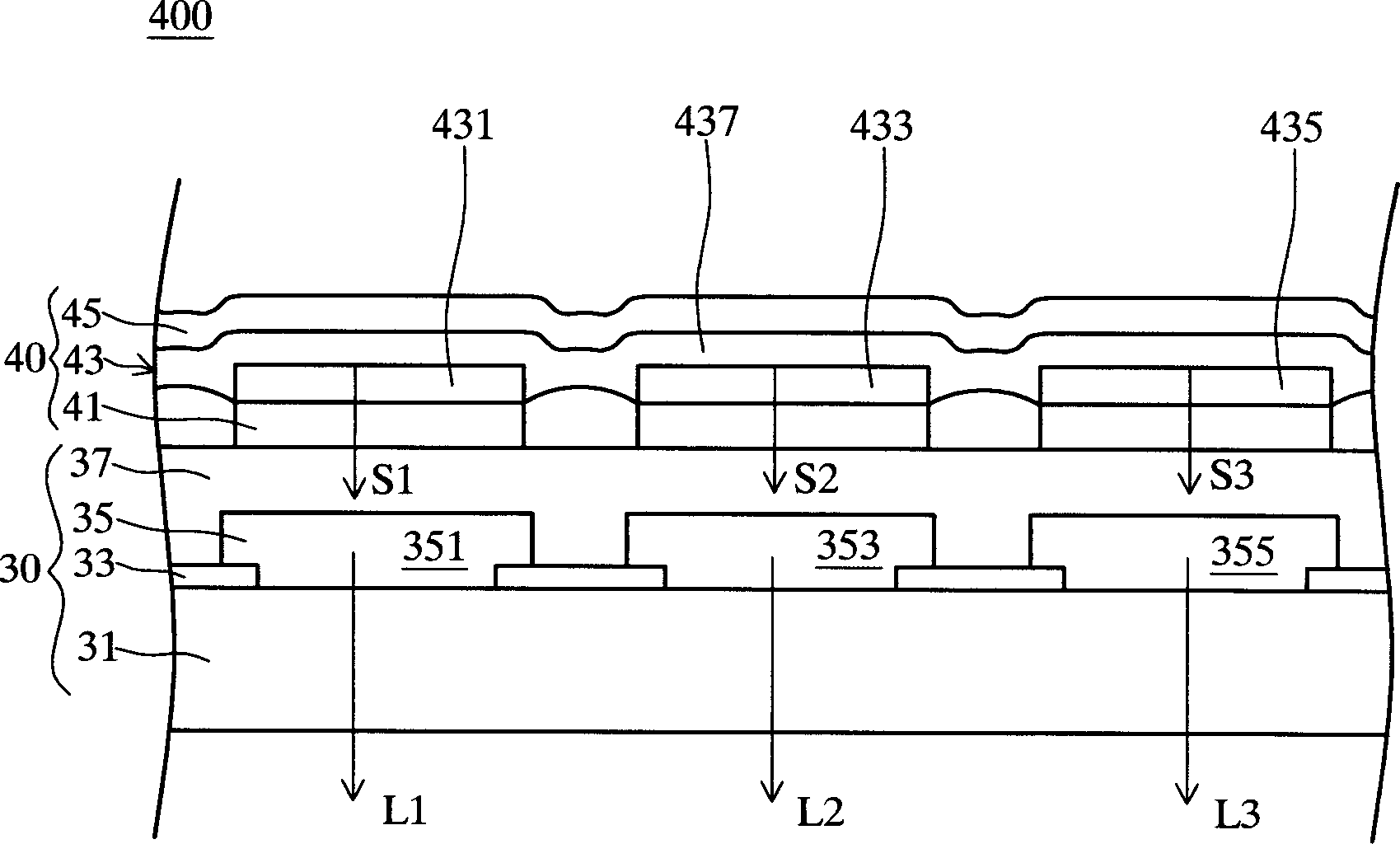

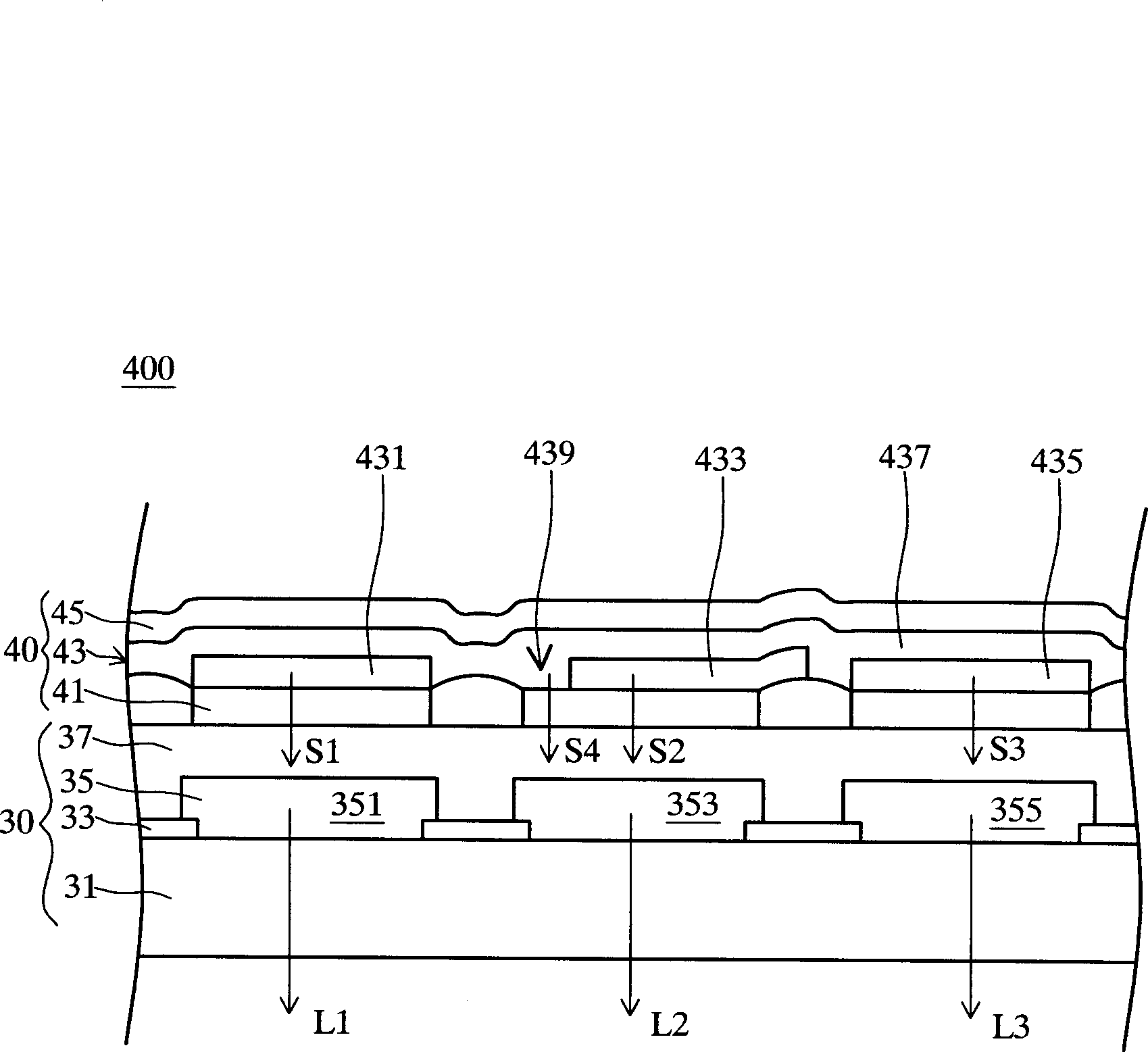

[0065] First, please refer to figure 2 and Figure 2A , are respectively a schematic cross-sectional view of a preferred embodiment of the improved side-by-side full-color organic electroluminescent display device of the present invention; as shown in the figure, the organic electroluminescent display device 400 of the present invention is mainly formed on a color filter 30 At least one organic electroluminescent component 40 is provided, wherein, the color filter 30 is mainly provided with a black matrix 33 (BlackMatrix) on a transparent substrate 31, and on part of the surface of the black matrix 33 and the transparent substrate 31 Where there is no black matrix 33, a color filter layer 35 (or color photoresist) with light color filtering function is added. The color filter layer 35 includes a first color photoresist 351 (such as R), a first color photoresist 351 The second color photoresist 353 (such as G) and the third color photoresist 355 (such as B). Furthermore, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com