Changable type carbon brush case for disc electric motor

A disc motor and carbon brush box technology, applied in the direction of rotating current collectors, circuits, current collectors, etc., can solve the problems of inability to take out or put in, inconvenient inspection or replacement of carbon brushes, etc., to achieve easy take out or put in Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

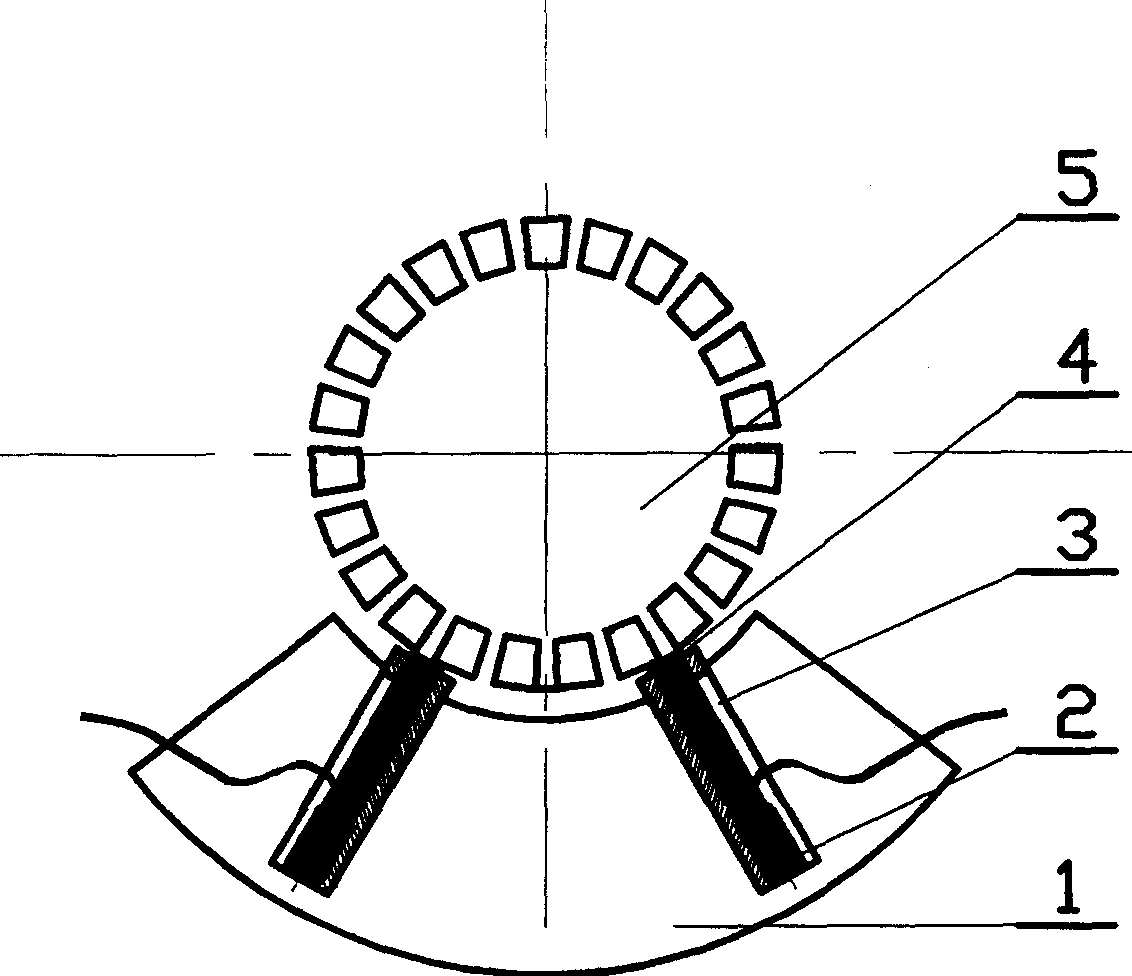

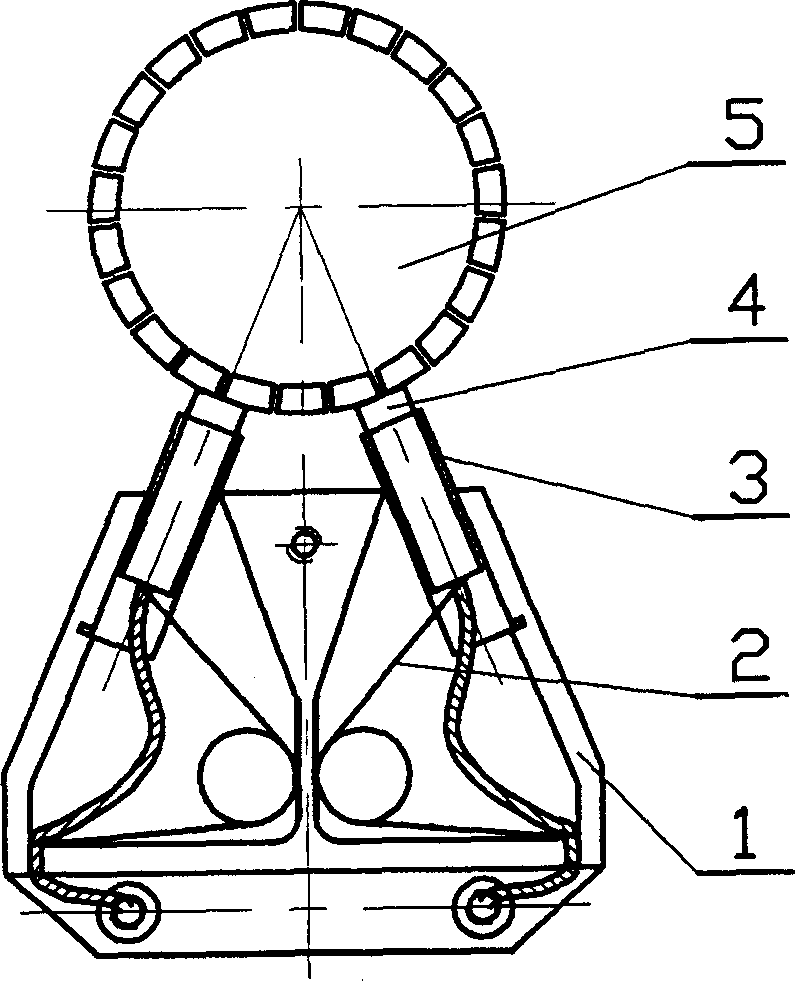

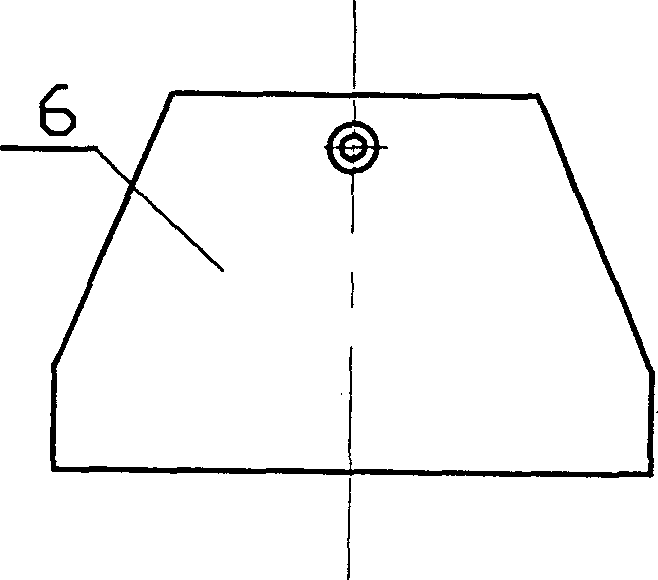

[0020] In a typical embodiment of the present invention, as figure 2 As shown, the replaceable carbon brush box for a disc motor includes a carbon brush box body 1, two copper sleeves 3 placed in the carbon brush box body at a set angle (such as 45° or 60°), respectively Two carbon brushes 4 that are movably installed in the two copper sleeves, and a support spring 2 that is arranged at the bottom of the carbon brush box body. The carbon brush box body is flat in this embodiment, and the cross-sectional shape of the carbon brush box body is trapezoidal in this embodiment. The carbon brush box body is detachably installed in the narrow housing of the disc motor (see Figure 5 ), in this embodiment, screwed on the narrow shell of the disc motor.

[0021] The end of one rotating arm of the support spring 2 is supported on the bottom of the carbon brush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com