Clutches

A clutch and clutch plate technology, applied in the field of clutches, can solve the problems of expensive progressive hydraulic control valves and imperfect systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

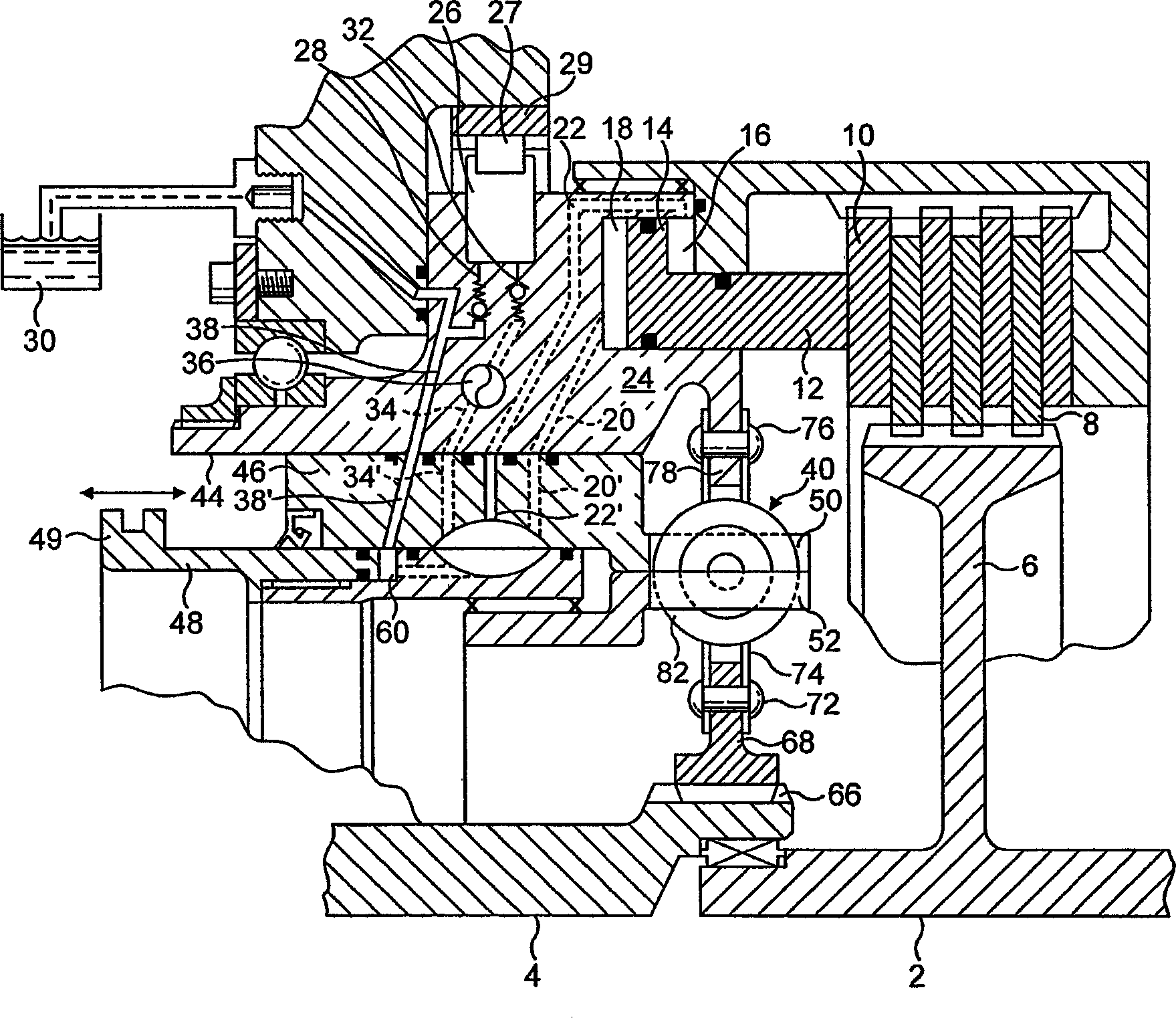

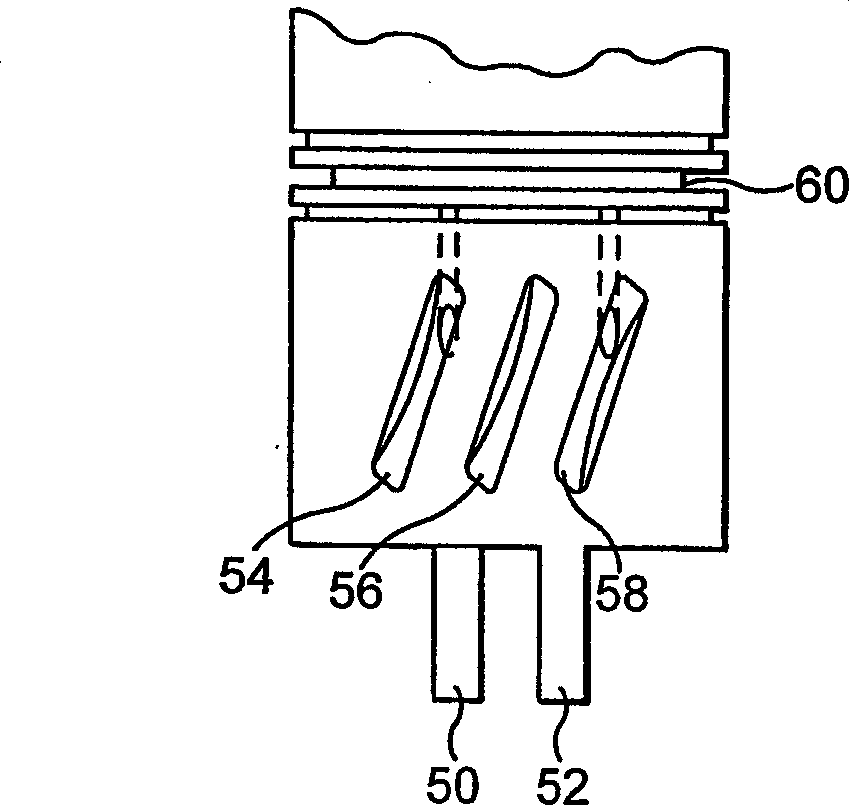

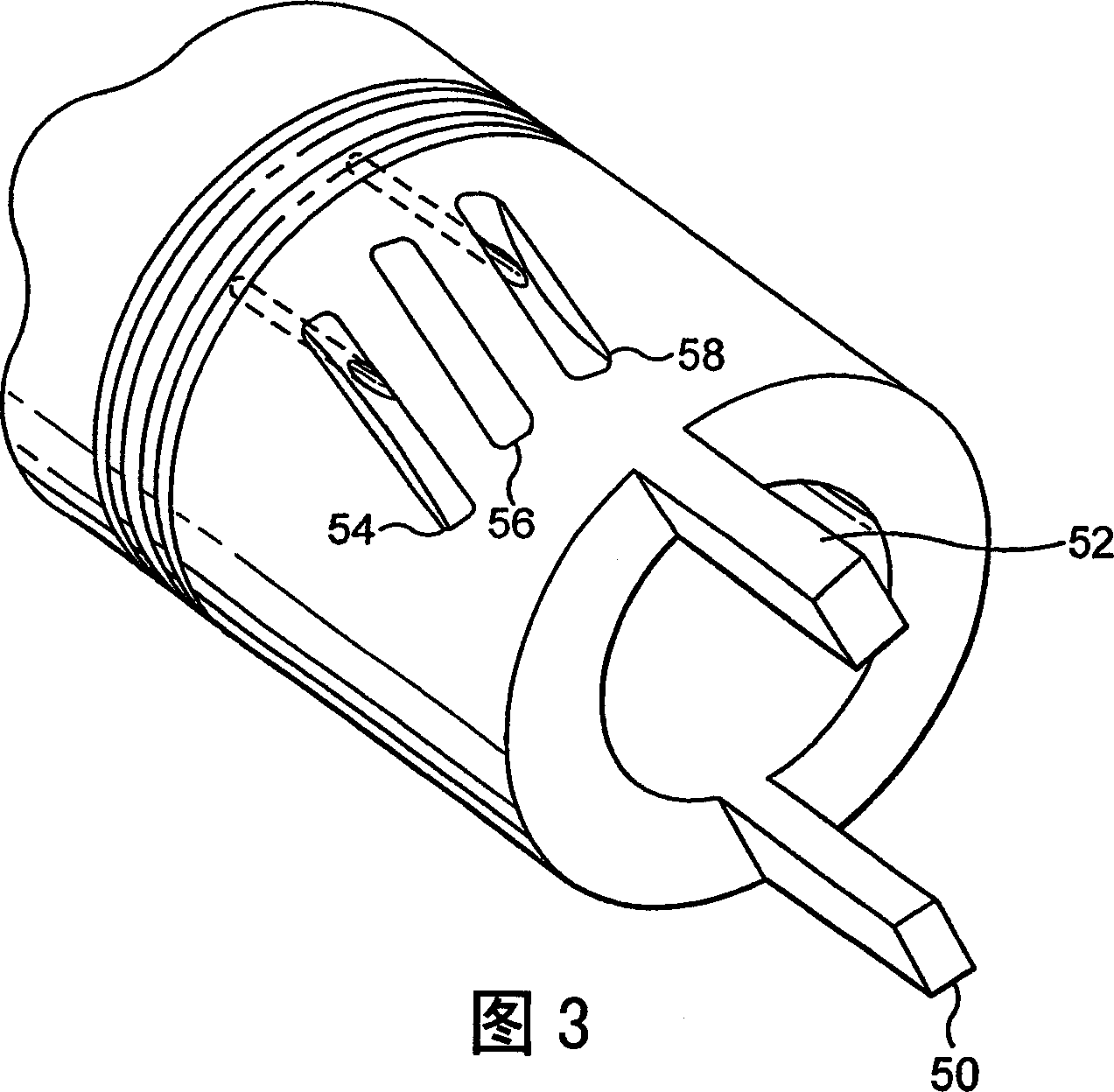

[0021] first reference figure 1 , the clutch includes an input shaft 2 and a coaxial output shaft 4 . A first set of annular clutch plates 8 meshes with a splined hub 6 carried by the input shaft 2, said first set of annular clutch plates cooperating with a second set of annular clutch plates 10 which are connected in Rotate together with the clutch body 24. Cooperating with the outermost clutch plate 10 is a clutch piston 12 , a part 14 of which is housed in a clutch cylinder whose interior is divided by the piston part 14 into two chambers 16 and 18 . Cavities 16 and 18 communicate with respective hydraulic fluid supply passages 20 and 22 extending within clutch body 24 . The clutch body 24 also accommodates a high-pressure hydraulic fluid pump 26, its inlet 28 communicates with an unpressurized hydraulic fluid tank or hydraulic fluid tank 30 via a check valve, and its outlet 32 communicates with another hydraulic fluid supply line 34 , the hydraulic fluid supply line 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com