A conductive composition and method of using the same

A conductive composition, conductive metal technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description is what is presently believed to be the best mode of carrying out the invention. This description is made to illustrate the general principles of the invention and is not to be considered limiting. The scope of the invention is best determined by reference to the appended claims.

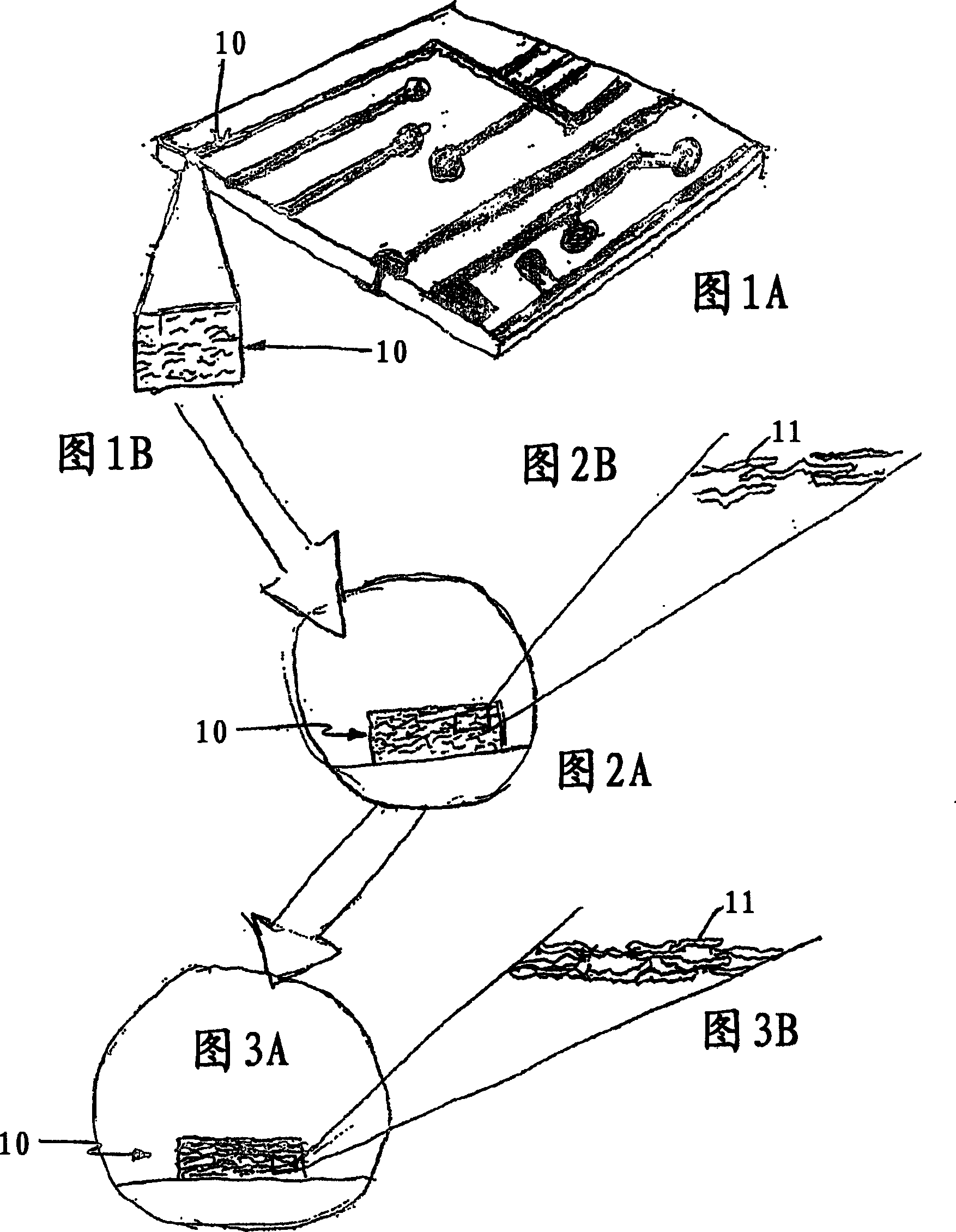

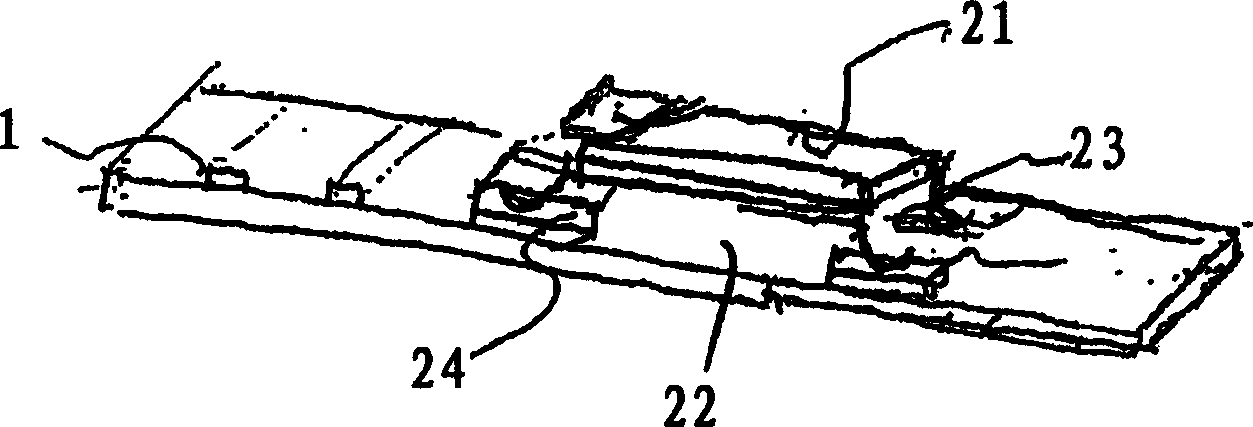

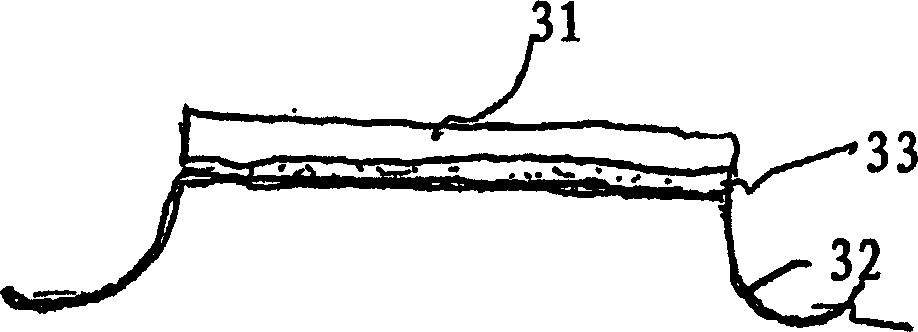

[0023] The invention discloses a conductive composition and a method for using the conductive composition. Referring particularly to FIGS. 1A and 1B , the conductive composition is typically applied to a substrate, preferably a non-conductive substrate such as a PCB, to form conductive traces 10 . PCBs can be manufactured, inter alia, from low melting temperature plastics such as polystyrene, which are not ideal for placement in conventional furnaces or ovens. It is understood that conductive traces 10 may be deposited on a wide variety of substrates. In other words, the substrate can be any type of substrate, from a PCB to even a layer of another composition such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com