High temperature steam centralized and safe processing method for medical refuse, and the device thereof

A technology of high-temperature steam and medical waste, which is applied in the direction of waste disinfection or sterilization, and can solve the problems of undeveloped technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

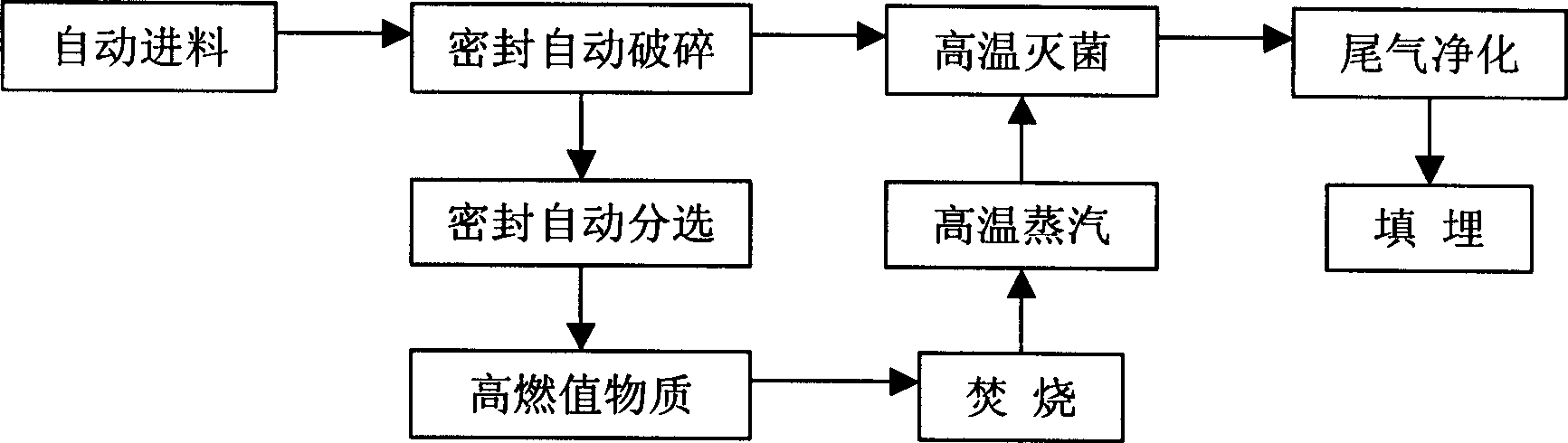

[0041] Such as figure 1 As shown, the infectious medical waste containing substances with high combustion value enters through the automatic feeding device, and is automatically sealed and crushed. Through automatic closed sorting, high combustion value substances in waste are separated. The incineration of high-combustion value substances can generate part of the heat for use by high-temperature steam. After automatic airtight sorting, the separated medical waste is sterilized under high-temperature steam. The treated waste is then treated with tail gas purification and finally landfilled.

[0042] When high-temperature steam treatment is performed, the sterilization temperature is 134°C. Before the high-temperature steam treatment, vacuumize by means of pre-vacuum, and the vacuum degree is 0.095MPa.

[0043] Sorting and crushing are strictly carried out under airtight conditions to prevent highly dangerous bacteria-carrying dust from overflowing.

[0044] Using thermoph...

Embodiment 2

[0046] Such as figure 1 As shown, the infectious medical waste containing substances with high combustion value enters through the automatic feeding device, and is automatically sealed and crushed. Through automatic closed sorting, high combustion value substances in waste are separated. The incineration of high-combustion value substances can generate part of the heat for use by high-temperature steam. After automatic airtight sorting, the separated medical waste is sterilized under high-temperature steam. The treated waste is then treated with tail gas purification and finally landfilled.

[0047] When high-temperature steam treatment is performed, the sterilization temperature is 134°C. Different from Embodiment 1, this embodiment is vacuumed in a pulsating vacuum manner, and the air extraction rate is higher than 93%.

[0048] Using thermophilic stearobacillus spores with strong heat resistance as the indicator species, the sterilization rate can reach the requirement ...

Embodiment 3

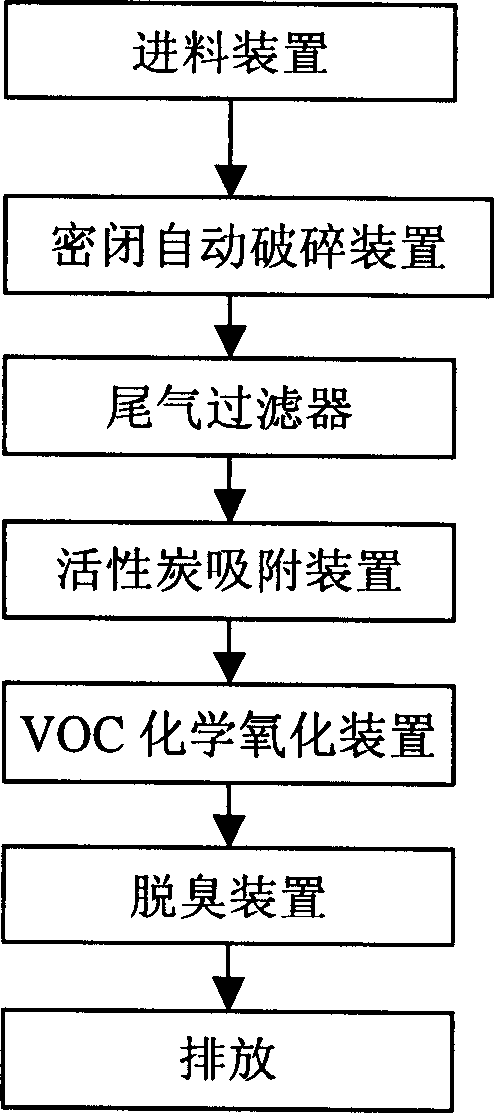

[0050] Such as figure 2 As shown, the high-temperature steam centralized safe disposal equipment for medical waste includes: a feeding device, a closed automatic crushing device, a high-temperature sterilization chamber, and an exhaust gas purification device, which are connected in sequence by pipelines.

[0051] The waste passes through the feeding device, is crushed in the closed automatic crushing device, and then enters the high-mix sterilization chamber for high-temperature steam treatment. In order to prevent secondary pollution, the equipment of the present invention is equipped with an exhaust filter. Since medical waste will cause a large amount of VOC to be produced, a VOC chemical oxidation device is also installed after the exhaust gas filter; finally, a deodorization device is also installed to improve the operating environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com