Electric permanent-magnet following clamp for delivery and its uses

A technology of accompanying fixtures and electric permanent magnets, applied in the direction of circuits, magnetic materials, electrical components, etc., can solve the problems that the position of the workpiece punching is prone to deviation, cannot ensure the accurate positioning of the workpiece laterally, and affects the quality of the punching of the workpiece, etc., to achieve Light weight, high resistance to lateral shearing, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

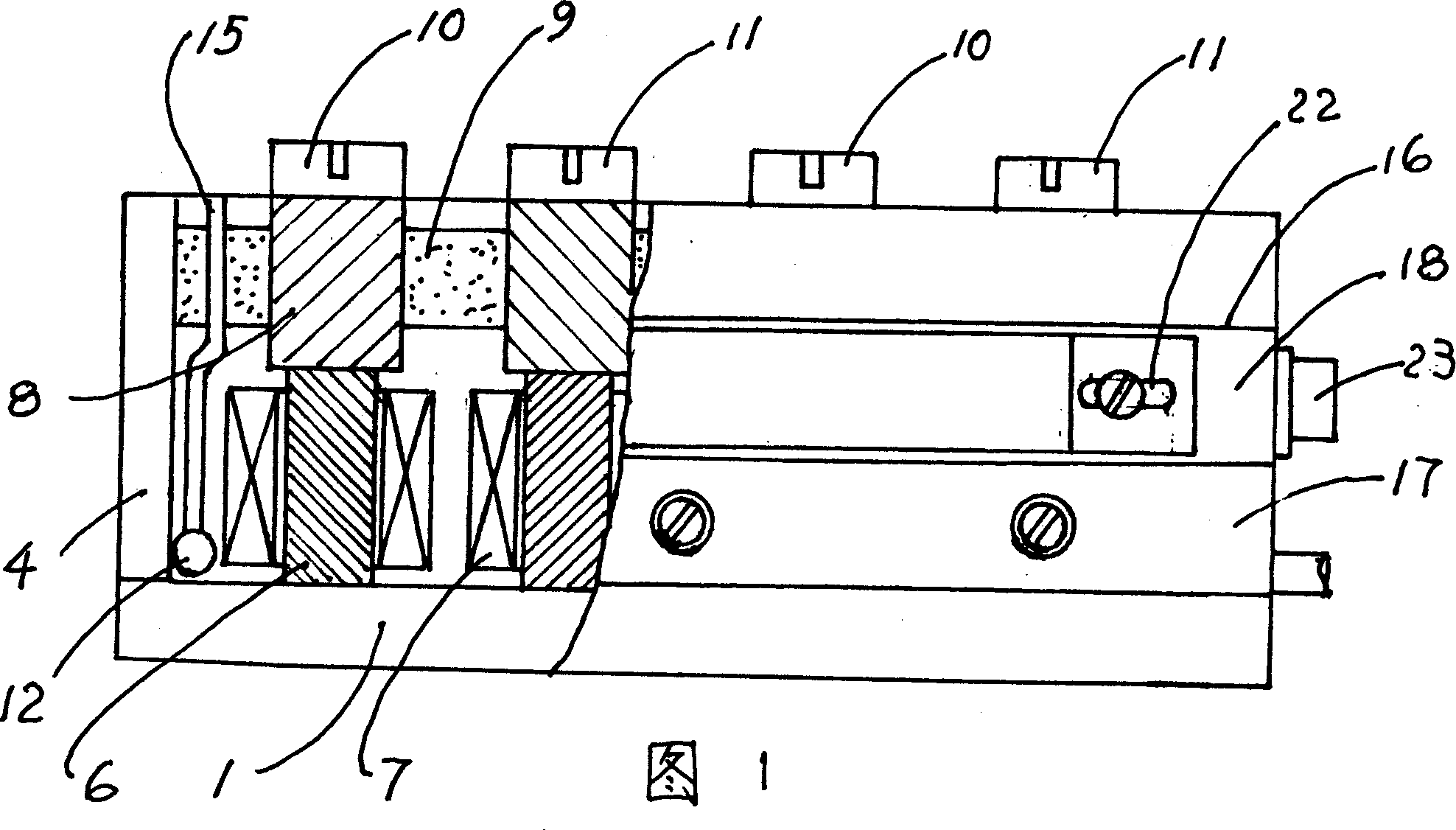

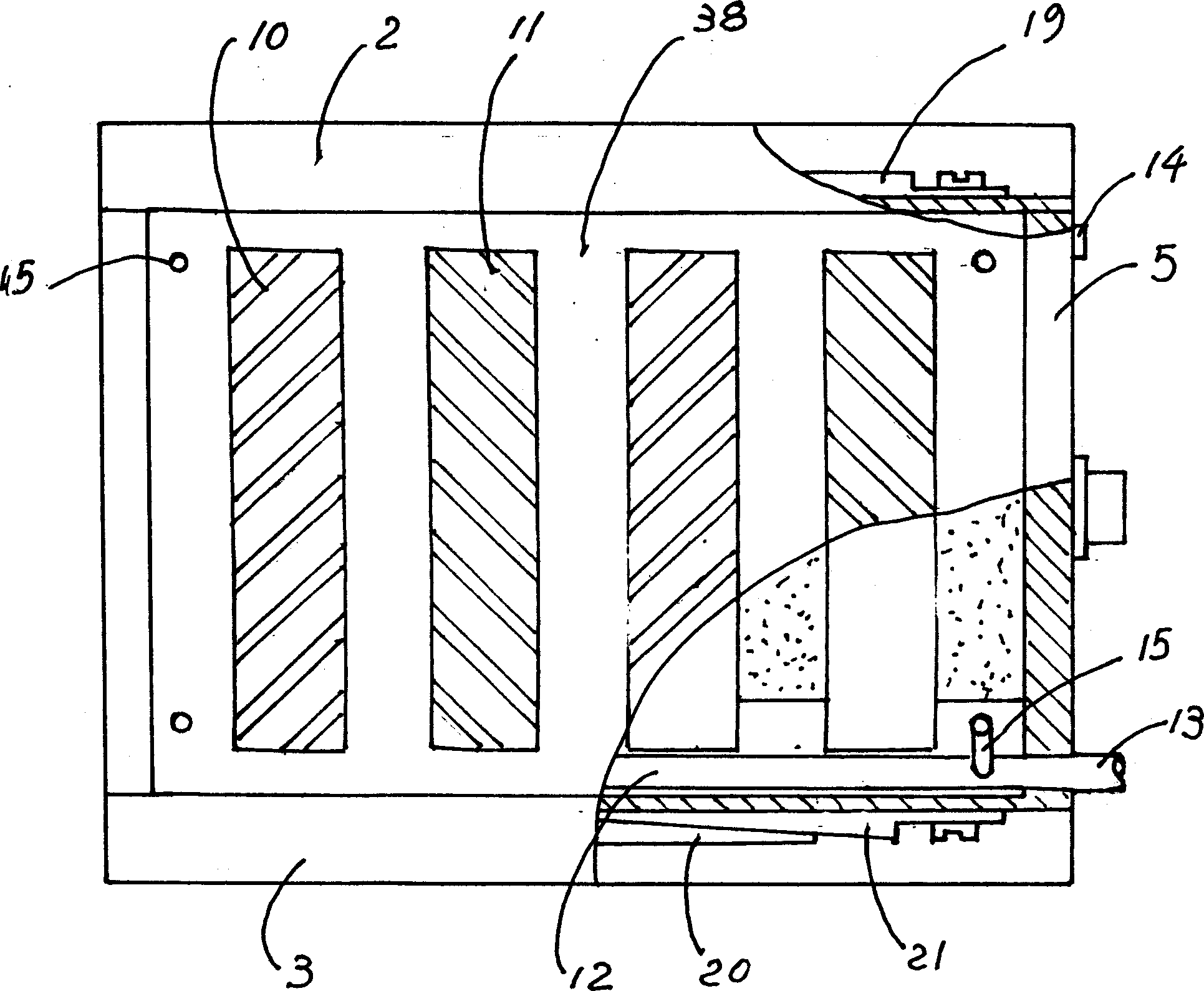

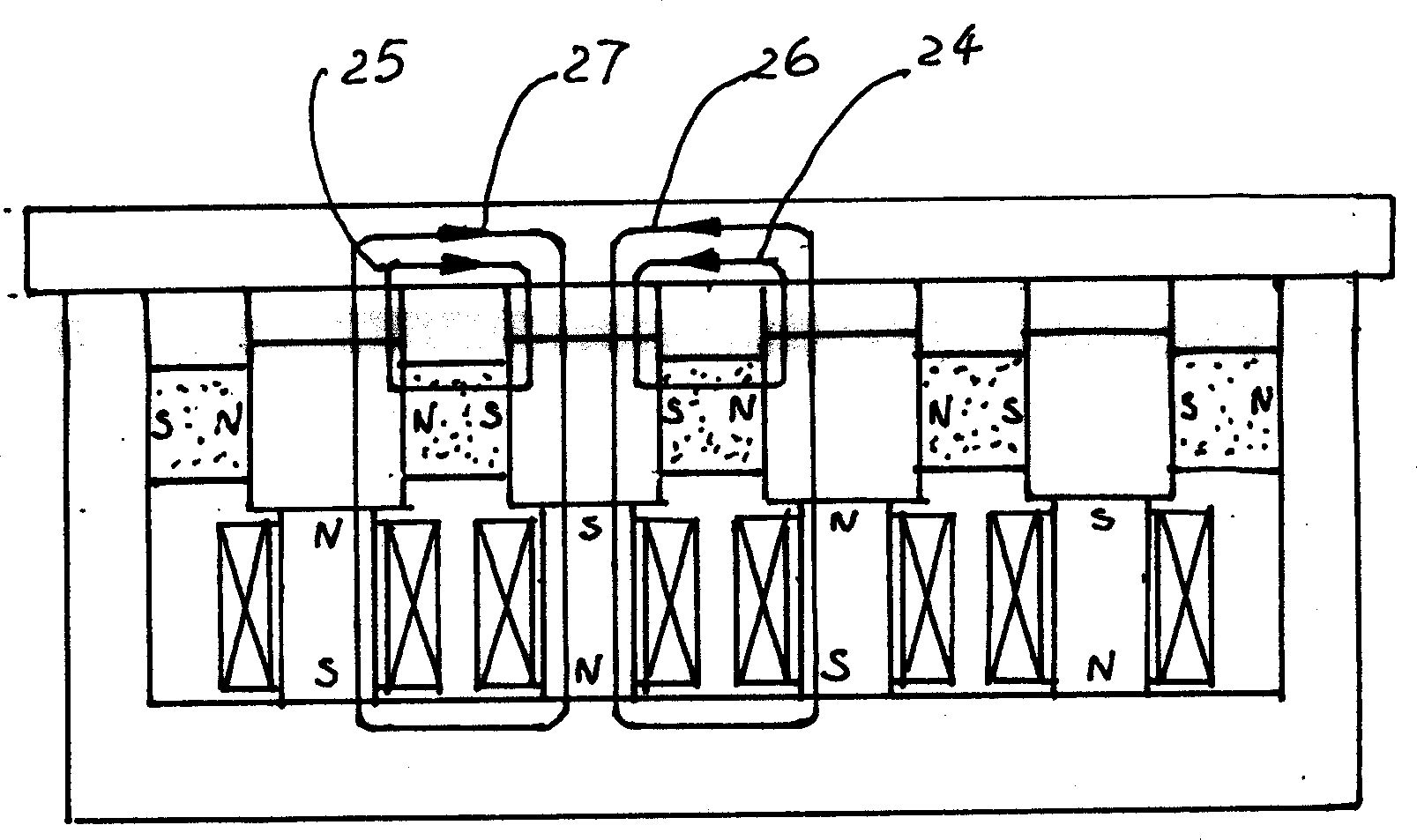

[0022] See Figure 1 and figure 2 , transfer electric permanent magnet accompanying fixture, including the accompanying fixture box surrounded by low-carbon steel bottom plate 1, side plates 2, 3 and end plates 4, 5, and 2-16 groups of AlNiCo are installed on the bottom plate 1 Combined reversible magnets 6 made of materials, each set of reversible magnets 6 is covered with excitation coils 7, each set of reversible magnets 6 is equipped with bar-shaped pole pieces 8, and between the bar-shaped pole pieces 8, N poles and S poles are alternated. The main magnet 9 inlaid with NdFeB material, and the strip-shaped pole pieces 8 are alternately fixed with heat-treated skimming pole caps 10 and stamping pole caps 11, so that the aforementioned pole caps have greater lateral shear resistance and better wear resistance. Considering that the pallet is clamped under the workpiece, when it is impacted and vibrated, dust or oxides are easy to fall on it, which will affect the magnetic for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com