Hydrodynamic bearing device and inspection method of amount of working fluid

A fluid bearing and working fluid technology, applied in bearings, electromechanical devices, bearing components, etc., can solve problems such as unstable rotation, decreased bearing rigidity, and reduced delivery volume, and achieve the effects of improving reliability and preventing fluid bearing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

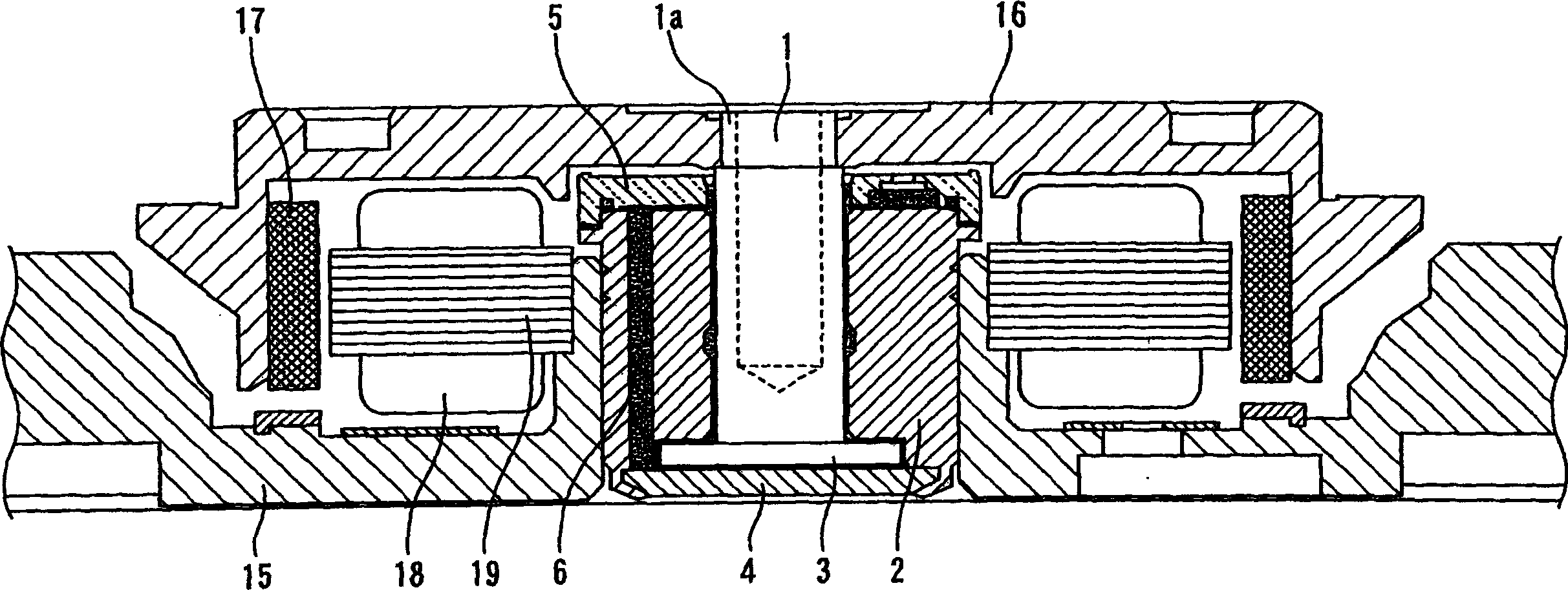

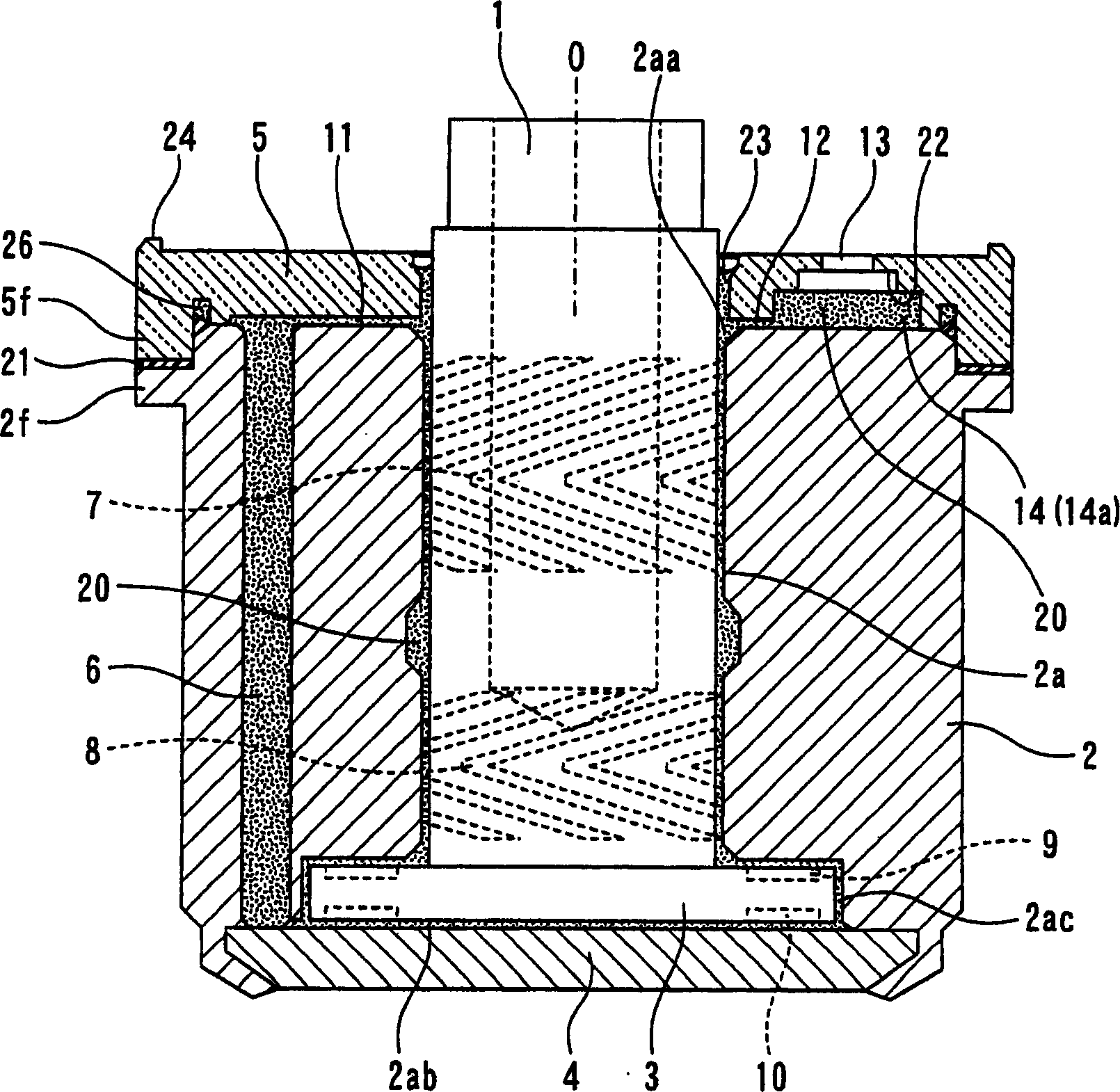

[0041] Hereinafter, a fluid bearing device and a method for inspecting the amount of working fluid thereof according to an embodiment of the present invention will be described with reference to the drawings. In this embodiment, a case where the fluid bearing device is used in a spindle motor of a hard disk drive will be described.

[0042] Implementation form 1:

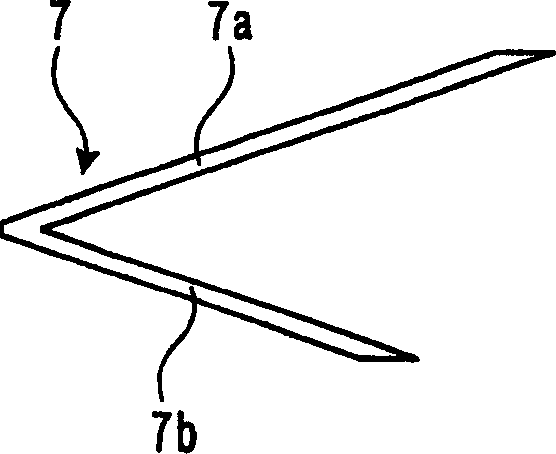

[0043] figure 1 is a cross-sectional view of a spindle motor having a fluid bearing device according to an embodiment of the present invention, Figure 2A is a sectional view of the fluid bearing device, image 3 is a top view of the fluid bearing device, Figure 2A yes image 3 The II-II line sectional view. In the following description, for easy understanding, such as figure 1 As shown in FIG. 2 , the case where the open end of the bearing hole of the bushing is arranged above and the closed end is arranged below is described, but it is of course not limited to such an arrangement in actual use.

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com