Linear motion device

A straight-forward, straight-line moving technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of insufficient thickener strength, unsatisfactory service life, lack of heat resistance and oil film retention, etc. Achieves the effects of inhibiting the formation of abnormal structures, relieving impact loads, and high surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

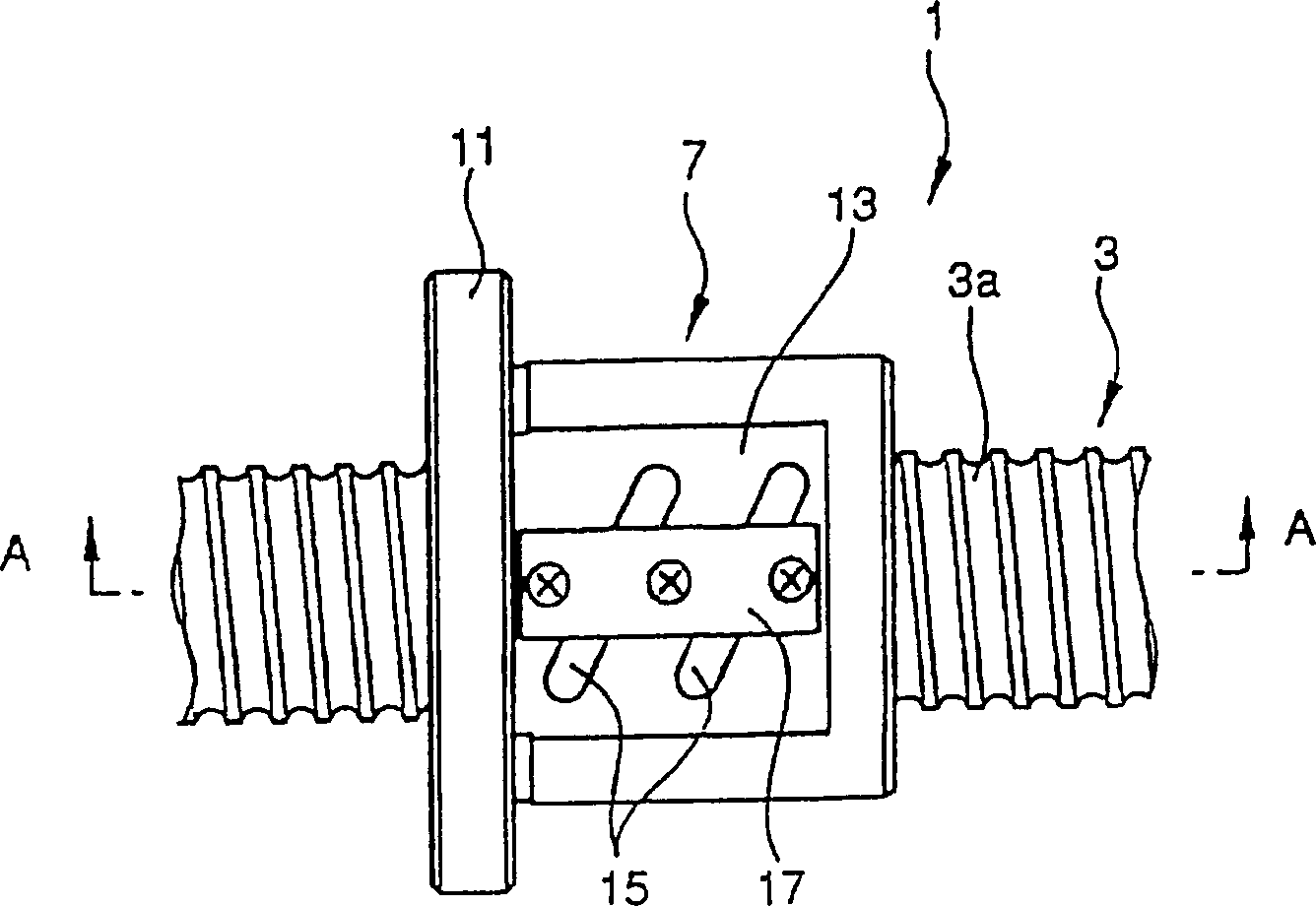

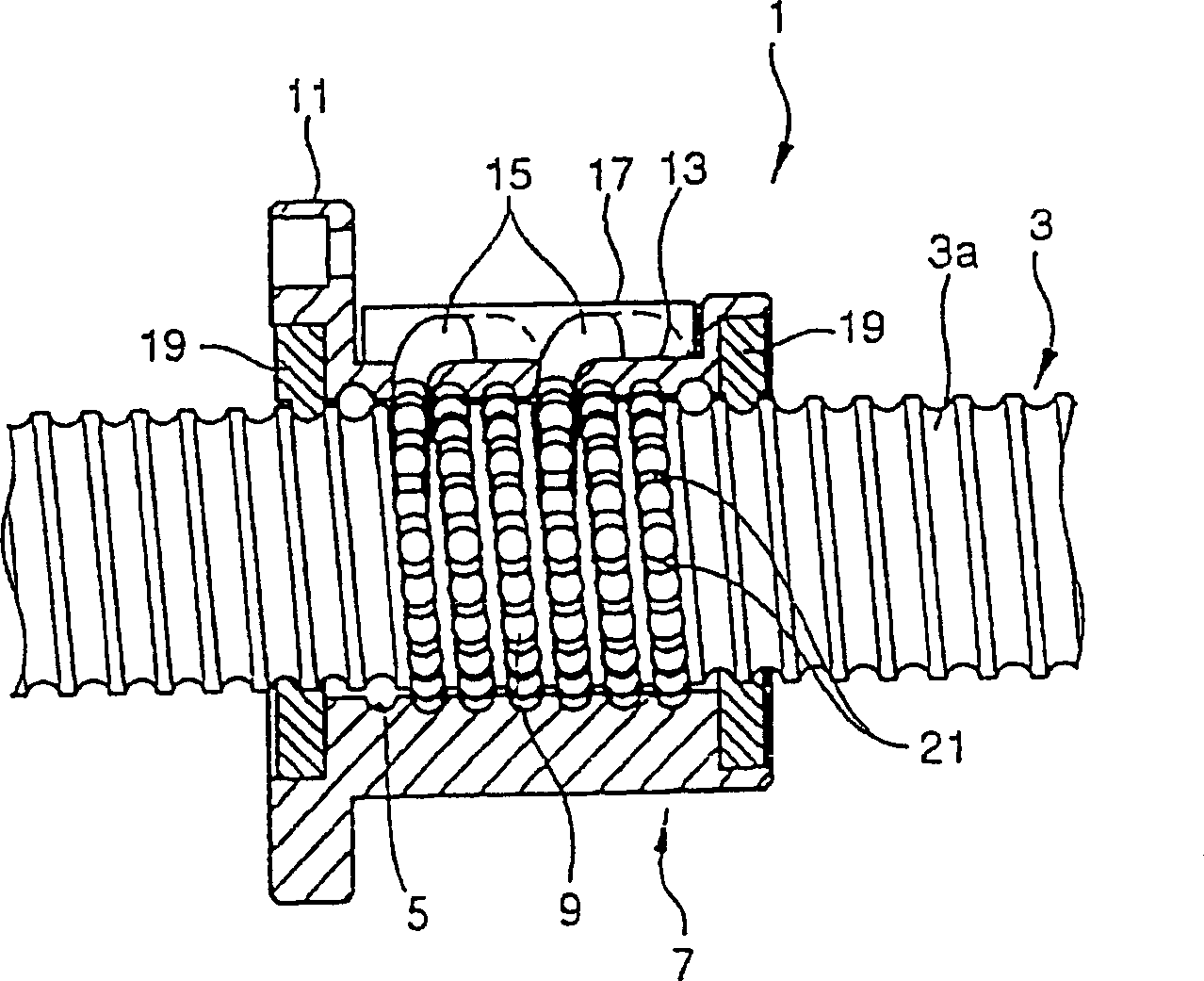

Image

Examples

Embodiment

[0175] Examples related to the straight-feeding device of the present invention and comparative examples compared with the examples will be described. That is, the tests of Examples 1 to 7 for confirming the effects of the straight-line device of the present invention and Comparative Examples 1 to 11 for comparison with the examples will be described.

[0176] In the test, a ball screw with a nominal number of 25×10×500-C5 according to JIS1192 was used, and a ball screw durability tester manufactured by NSK was used under the following test conditions to record the time when damage such as abrasion or peeling occurred.

[0177] Using the Weibull function distribution, within 10 samples, the time to reach 10% of the life of the ball screw from the side with the shortest life was obtained, and this was used as the test life.

[0178] Calculate the theoretical life time under each test condition, and express the test result as the ratio of the test time to the theoretical life ti...

Embodiment 23 and Embodiment 24

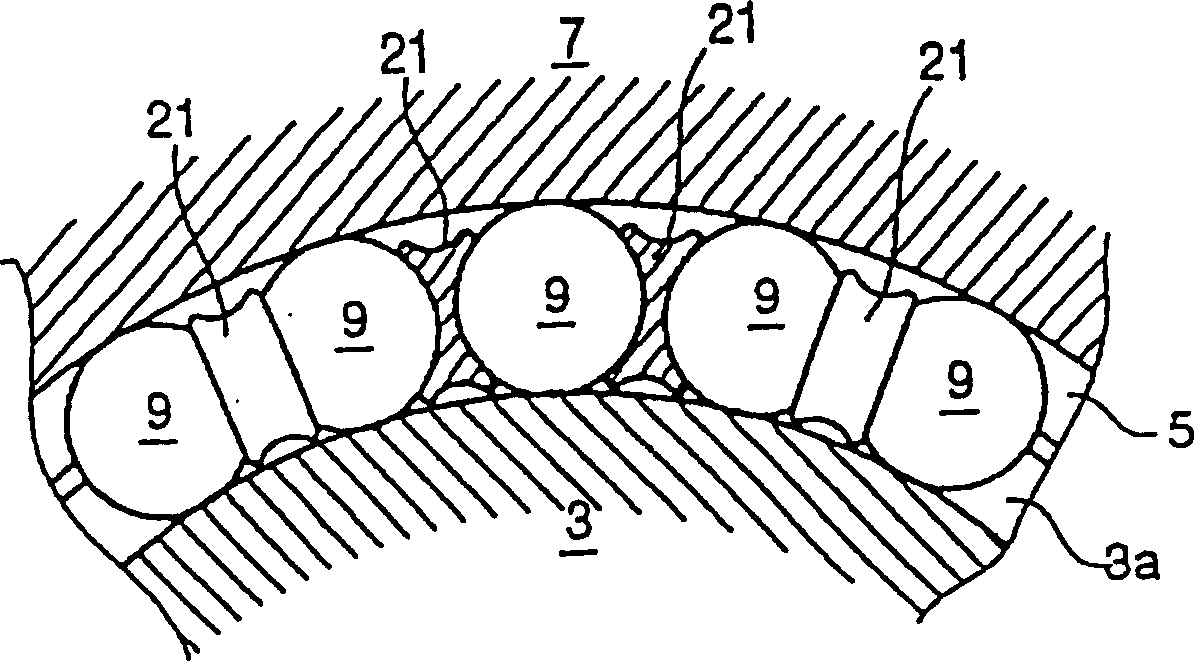

[0309] In Example 23 and Example 24, the male thread groove of the threaded shaft has a radius of curvature within the range specified in this embodiment, but the radius of curvature of the female thread groove of the nut is smaller than the radius of curvature within the range specified in this embodiment.

[0310] Radius of curvature of threaded shaft / ball diameter (%)

[0311] The holder is made of nylon, the concave surface facing the ball is conical, and the outer diameter is 0.8 times the diameter of the ball. In addition, when it is assumed that the total clearance S1 is greater than 0 (S1>0) and one retainer at the rear end is removed, the clearance (S2) between the ball at the beginning and the ball at the rear end is set to be smaller than the outer diameter (ds) of the retainer 0.8 times (S2<0.8×ds).

Embodiment 26

[0434]In the test ball screw of Example 26, a grease composition containing zinc naphthenate in an amount ranging from 0.05 to 12% by mass was enclosed, and in the test ball screw of Example 27, the content of succinic acid half ester was enclosed in a range of 0.05 to 12% by mass. Grease compositions varied in the range of 12% by mass, the test ball screw of Example 28, and grease compositions in which the content of nickel dithiocarbamate was varied in the range of 0.05 to 12% by mass.

[0435] exist Figure 12 shows the measurement results of the peeling life of the test ball screw used in Example 26 and Example 27, and the peeling life ratio of the test ball screw used in Comparative Example 26 as 1.0. Depend on Figure 12 It can be seen that the peeling life of the ball screw can be greatly improved by enclosing a grease composition containing 0.1 to 10 mass of zinc naphthenate or succinic acid half ester.

[0436] In addition, in Figure 13 shows the results of the pe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap