Engine exhaust pipe residual heat generating method and its device

A waste heat power generation and power generation device technology, which is applied to exhaust devices, engine components, combustion engines, etc., can solve problems such as waste and energy waste, and achieve the effects of energy saving, no cost, and energy stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

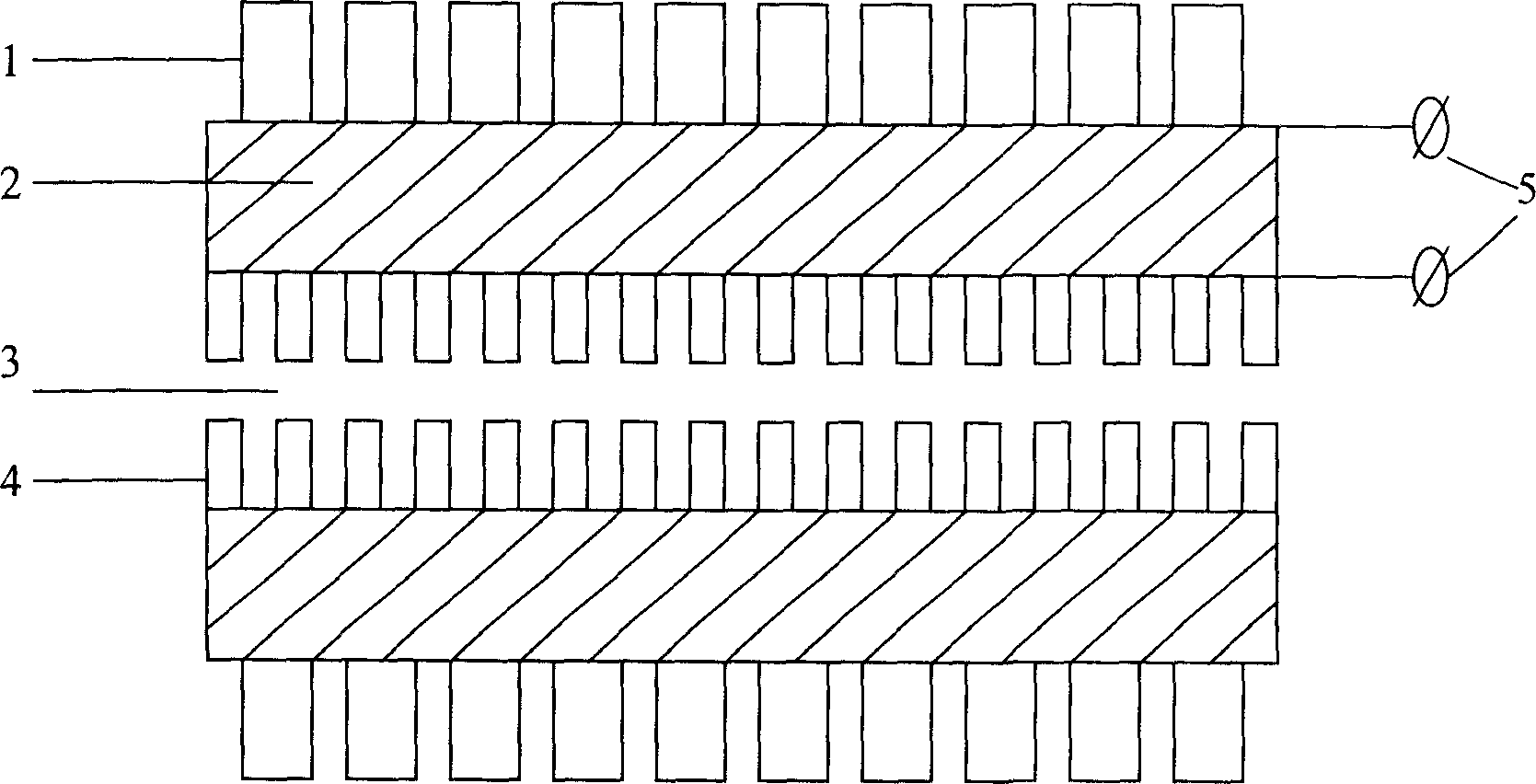

[0017] according to figure 1 As shown, the main body 2 of the power generation device is a tubular structure, the wall of which is the main body 2 of the thermoelectric converter, the middle part is the exhaust pipeline channel 3, the outer layer is provided with a low-temperature cooling end 1, and the inner wall is provided with a high-temperature heat-absorbing end 4. The cooling end 1 and the high-temperature heat-absorbing end 4 are both designed as fin-shaped structures, and the low-temperature cooling end 1 of the thermoelectric converter is cooled by the vehicle body and air, and the current output terminal 5 is respectively connected to the low-temperature cooling end 1 and the high-temperature heat-absorbing end 4 .

Embodiment 2

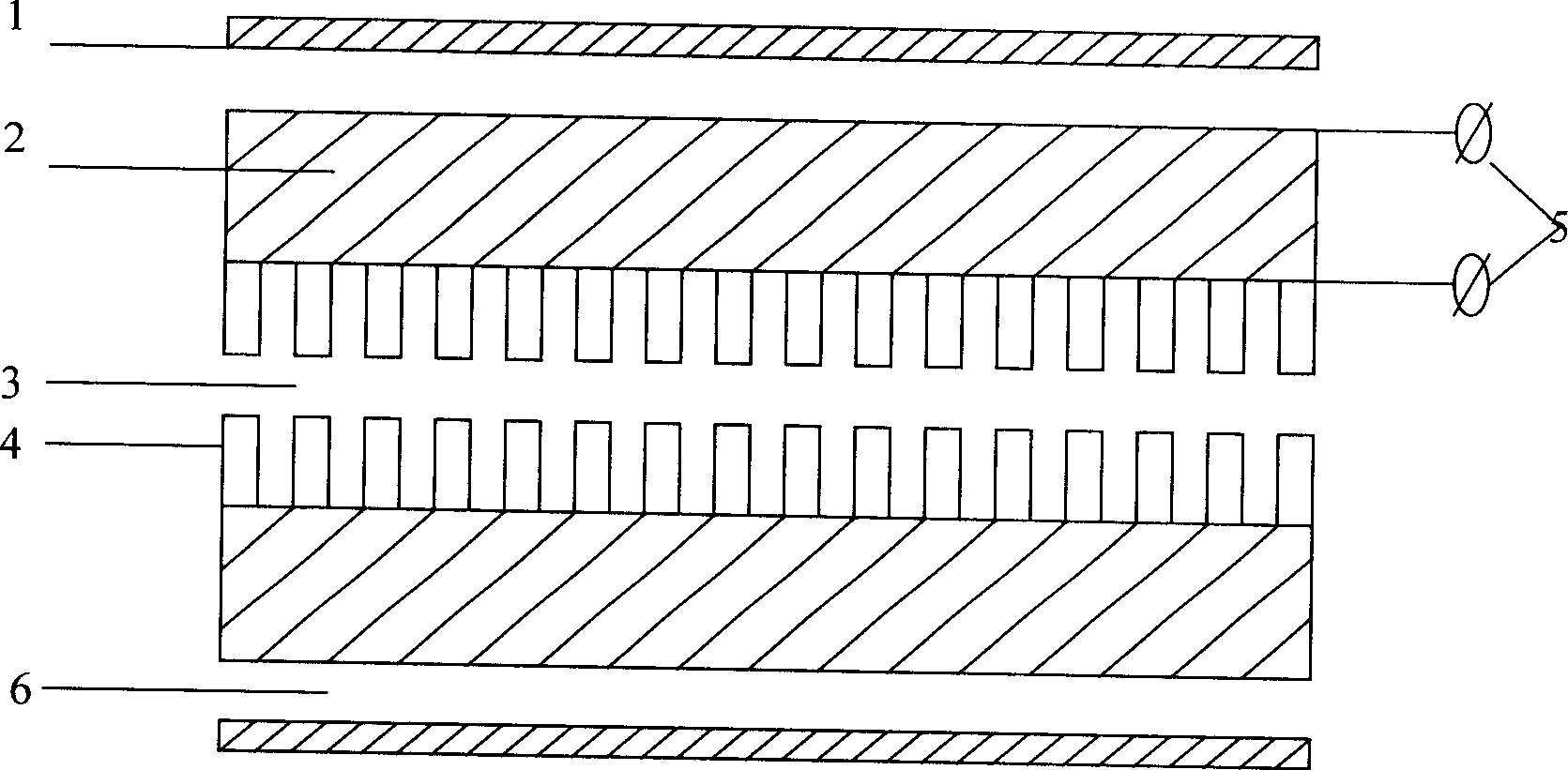

[0019] refer to image 3 , the low-temperature cooling end 1 of the utility model can also be designed as a water-cooled structure, and a cooling water channel 6 is provided between the thermoelectric converter main body 2 and the low-temperature cooling end 1, which can be connected with the water circulation cooling system of the engine, and the low-temperature The end can be directly cooled with water, which is more convenient and practical.

Embodiment 3

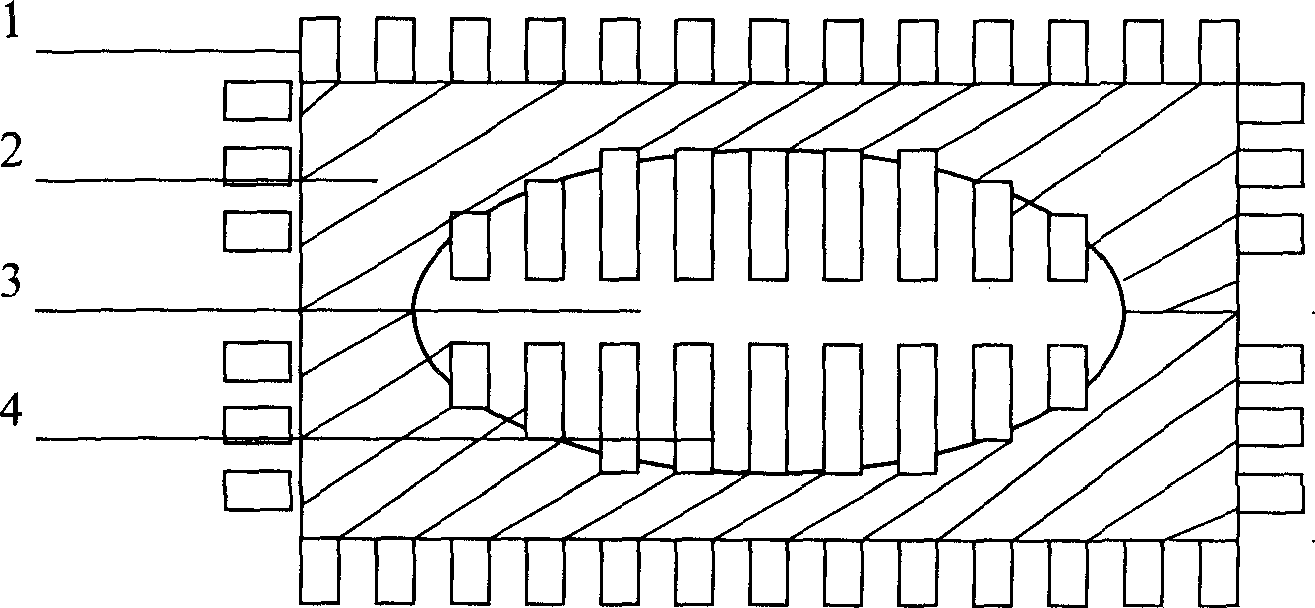

[0021] The above materials are made into thermoelectric conversion devices of different shapes such as circular or elliptical according to the shape of the vehicle and ship exhaust pipe (see figure 2 ), installed on the vehicle and ship can be used. The output power can be directly charged into the battery or used by other electrical appliances.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com