Valve tappet of internal-combustion engine, and process technology

A processing technology and internal combustion engine technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of non-wear-resistant internal combustion engine valve lifters, and achieve the effect of enhancing wear resistance and improving stability

Inactive Publication Date: 2006-07-05

许沂蒙

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to solve the problem that the valve tappet of the current internal combustion engine is not wear-resistant, and to design a wear-resistant valve tappet

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

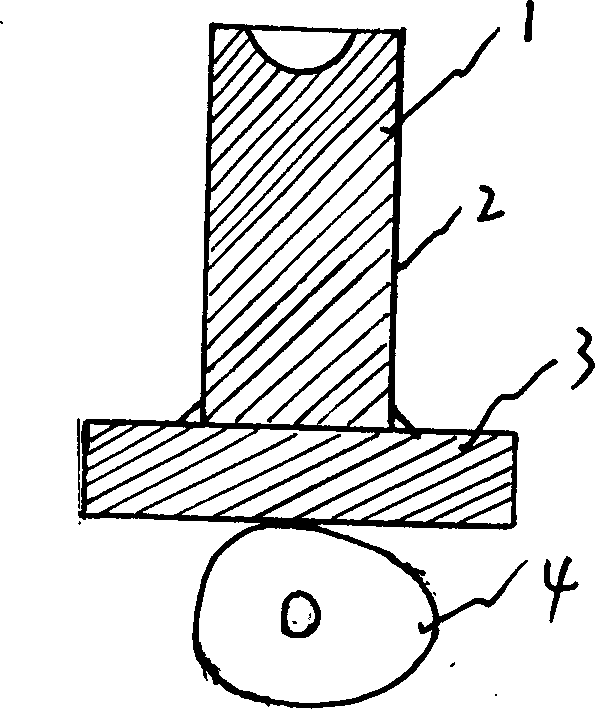

[0012] Such as figure 1 As shown, the valve tappet 1 is welded by a column body 2 made of carburized steel and a chassis 3 made of chrome steel. Since the chassis 3 is made of chrome steel with strong wear resistance, the Enhanced wear resistance when rubbing with cam 4.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A method for preparing valve lifter of air door on combustion engine includes applying carbonized steel or iron ball being chill ¿C treated as valve lifter body material and applying Man steel or Cr steel with high antifriction property as chassis material, welding two said components prepared by different materials together to form an integral body.

Description

[0001] Technical collar: [0002] The invention relates to a valve mechanism of an internal combustion engine, in particular to a valve tappet of an internal combustion engine and its processing technology. Background technique: [0003] The valve mechanism of the internal combustion engine is an important part of the entire gas distribution system. According to the different types of engines, one is that the valve is driven by a cam to drive the tappet, and then the tappet pushes the valve; the other is that the cam drives the tappet, push rod and The rocker arm pushes the valve. Regardless of the driving method, the cam directly rubs against the tappet. The current tappet body and the chassis are processed into one piece of metal material. Over time, with the wear of the tappet, the valve clearance gradually increases. , affecting the efficiency of the engine. Invention content: [0004] The purpose of the present invention is to solve the problem that the valve lifter o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F01L1/14

Inventor 许沂蒙

Owner 许沂蒙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com