Drilling string torsional energy control assembly and method

A technology for controlling components and drill strings, which is applied in the automatic control system of drilling, earth-moving drilling, drilling equipment, etc., can solve problems such as the inability to provide reliable sliding adhesion devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

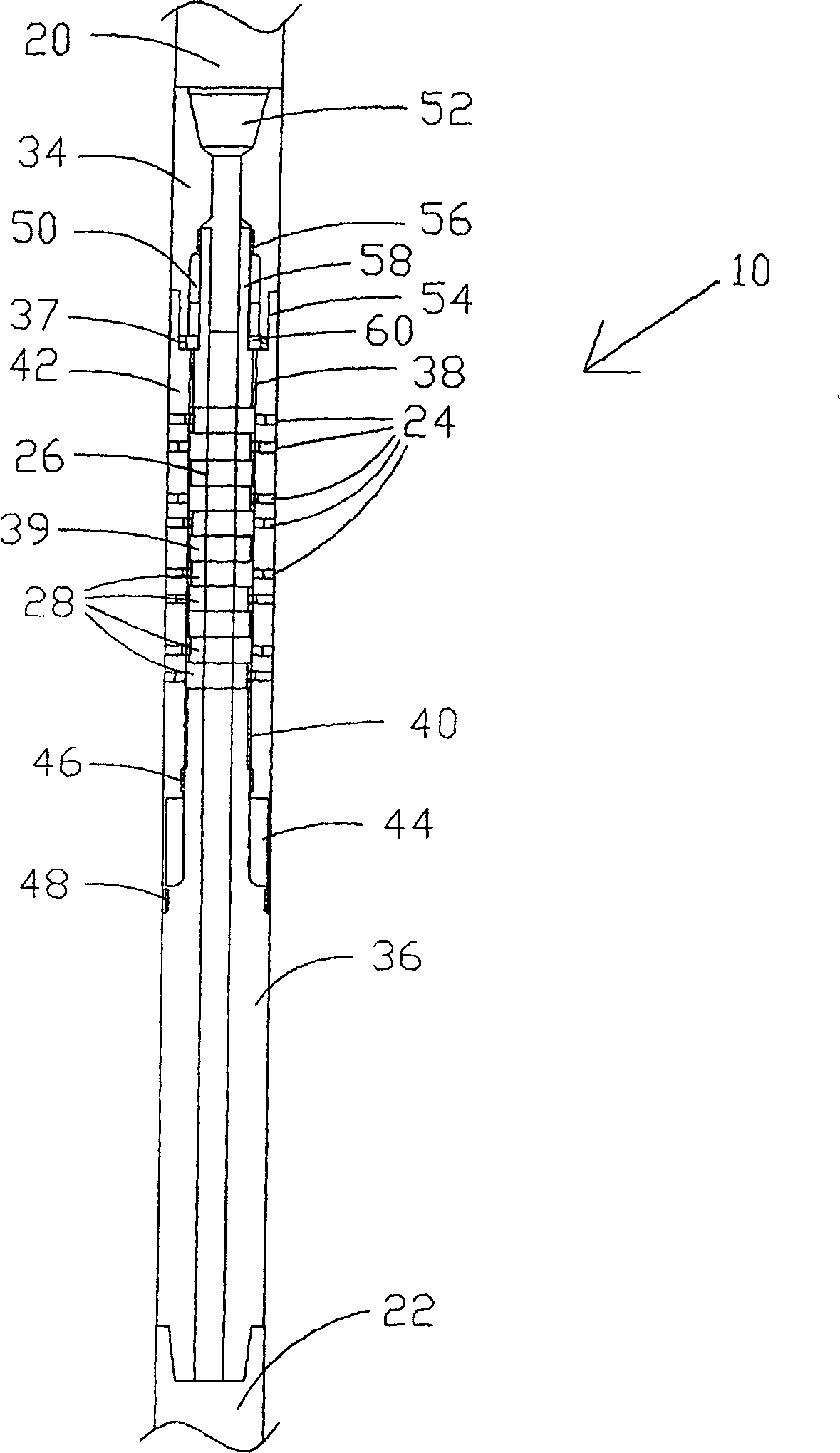

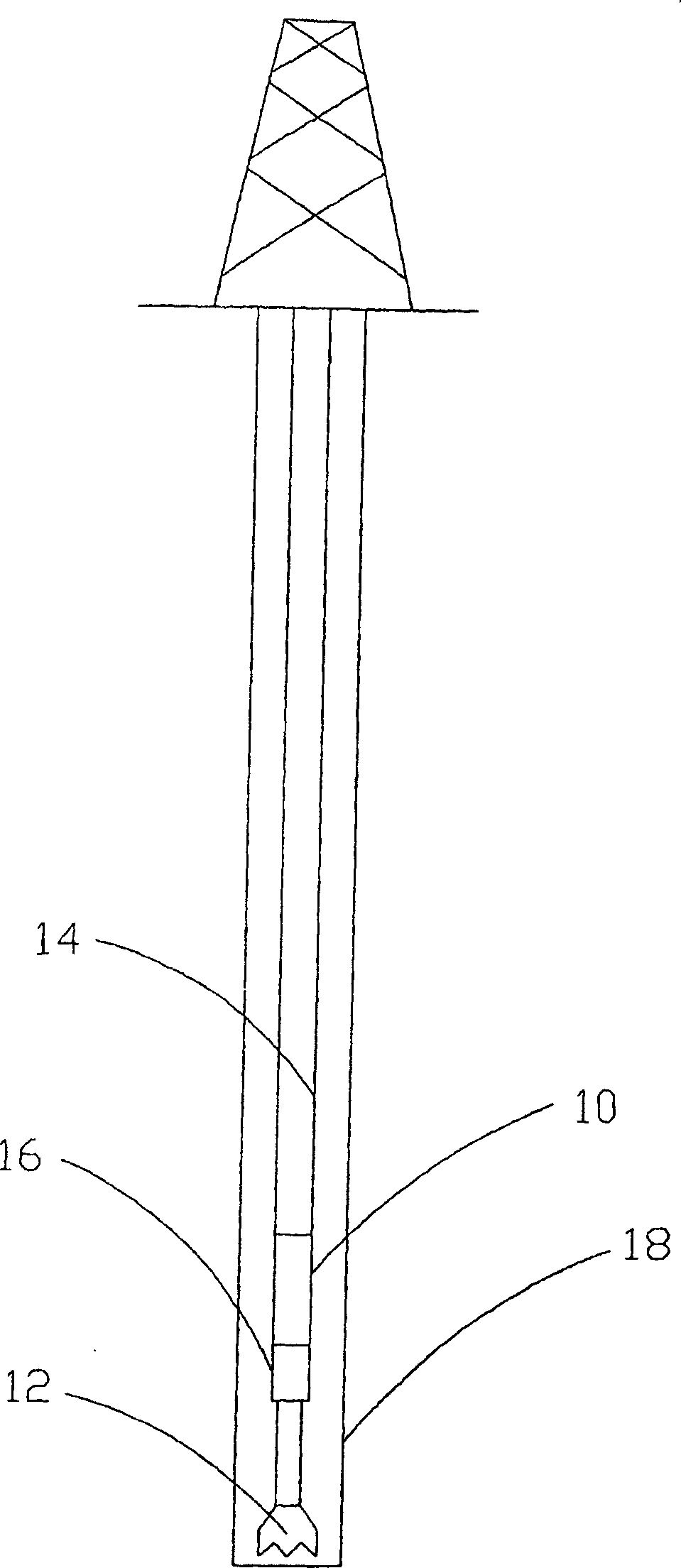

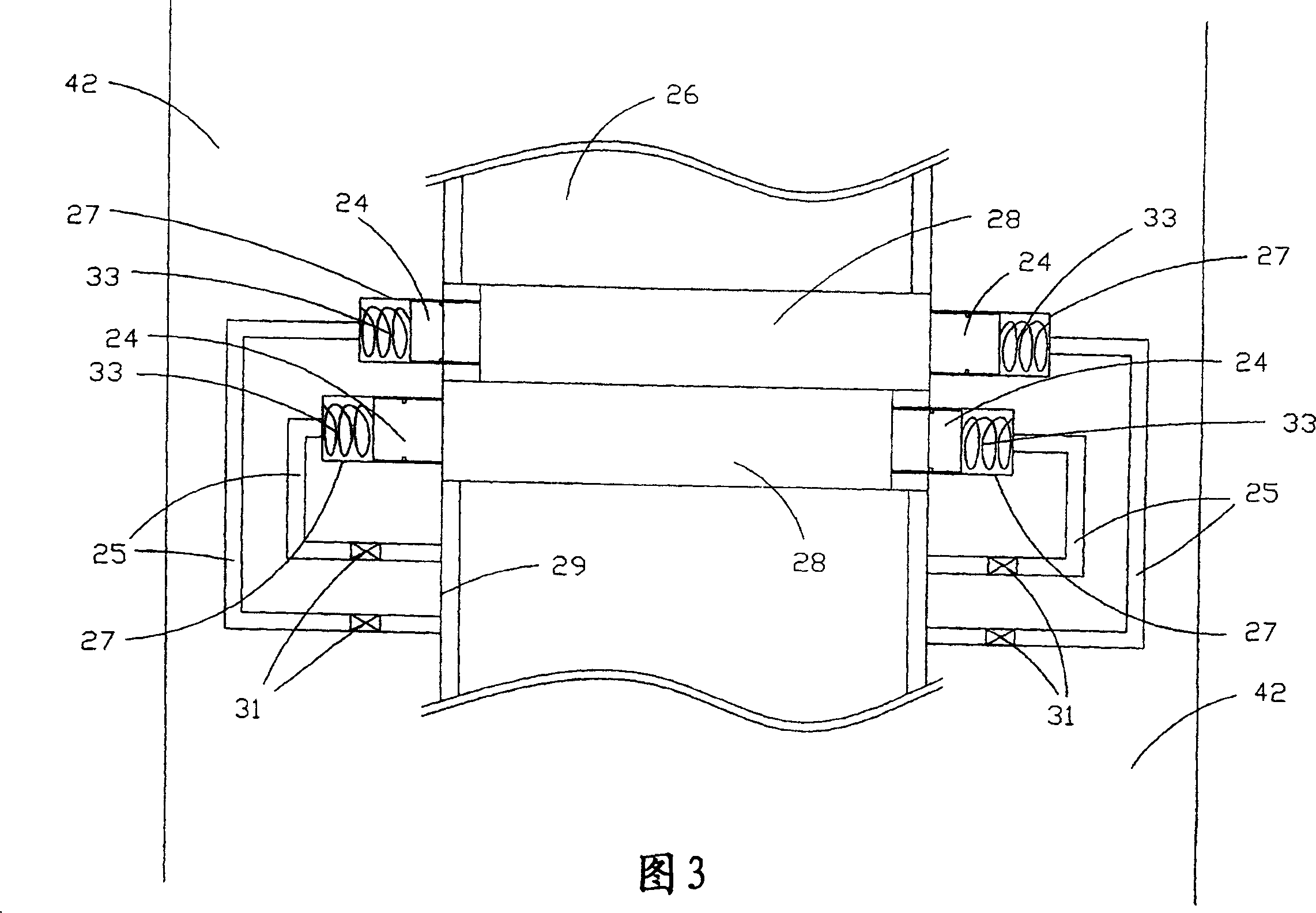

[0044] Referring now to the drawings, and more particularly to the figure 1 and figure 2 , these figures show a downhole rotation control assembly 10 that may be used in drilling, drilling and / or in other applications that require the drill string to transmit torque, typically to the bottom hole assembly and drill bit. Although a specific embodiment of the rotary control system 10 is provided herein, the rotary control assembly 10 may also include any mechanism operable to connect and disconnect torque between the shaft or drilling tubular section to eliminate torsional oscillations, And thereby control the torsional energy in the drill string. Accordingly, the rotary control assembly 10 may include an on-off clutch that substantially or completely connects (engages) two rotary shafts and / or two drilling tubular sections and / or a drilling tubular section and drill bit for torque transmission , but can also be substantially or completely disconnected (disengaged) for little ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com