Lubricant gun

A sliding box and equipment technology, applied in manual lubricant supply, engine lubrication, mechanical equipment, etc., can solve the problem that the lubricant gun is easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

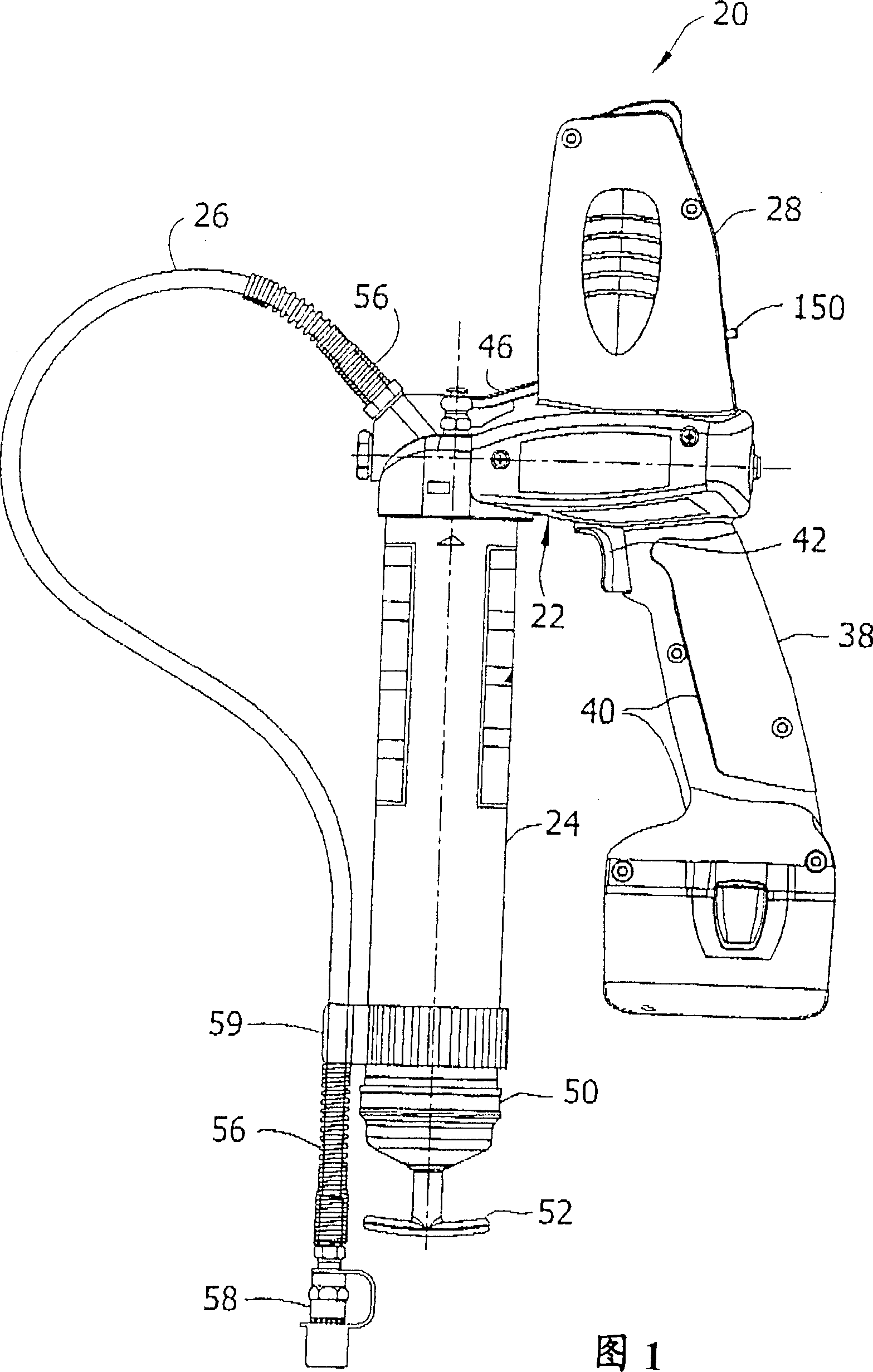

[0035] Referring now to the drawings, and in particular to FIG. 1 , an apparatus for dispensing viscous fluids according to the present invention is indicated generally at 20 . In the embodiment shown in the drawings, the device is a portable hand-held lubricant gun for dispensing lubricant, although other embodiments do not depart from the scope of the invention. Lubricant gun 20 includes a pump mechanism, generally indicated at 22, which delivers lubricant from a reservoir (tank) 24 via a discharge, such as a flexible hose 26, to the machine or vehicle requiring lubrication.

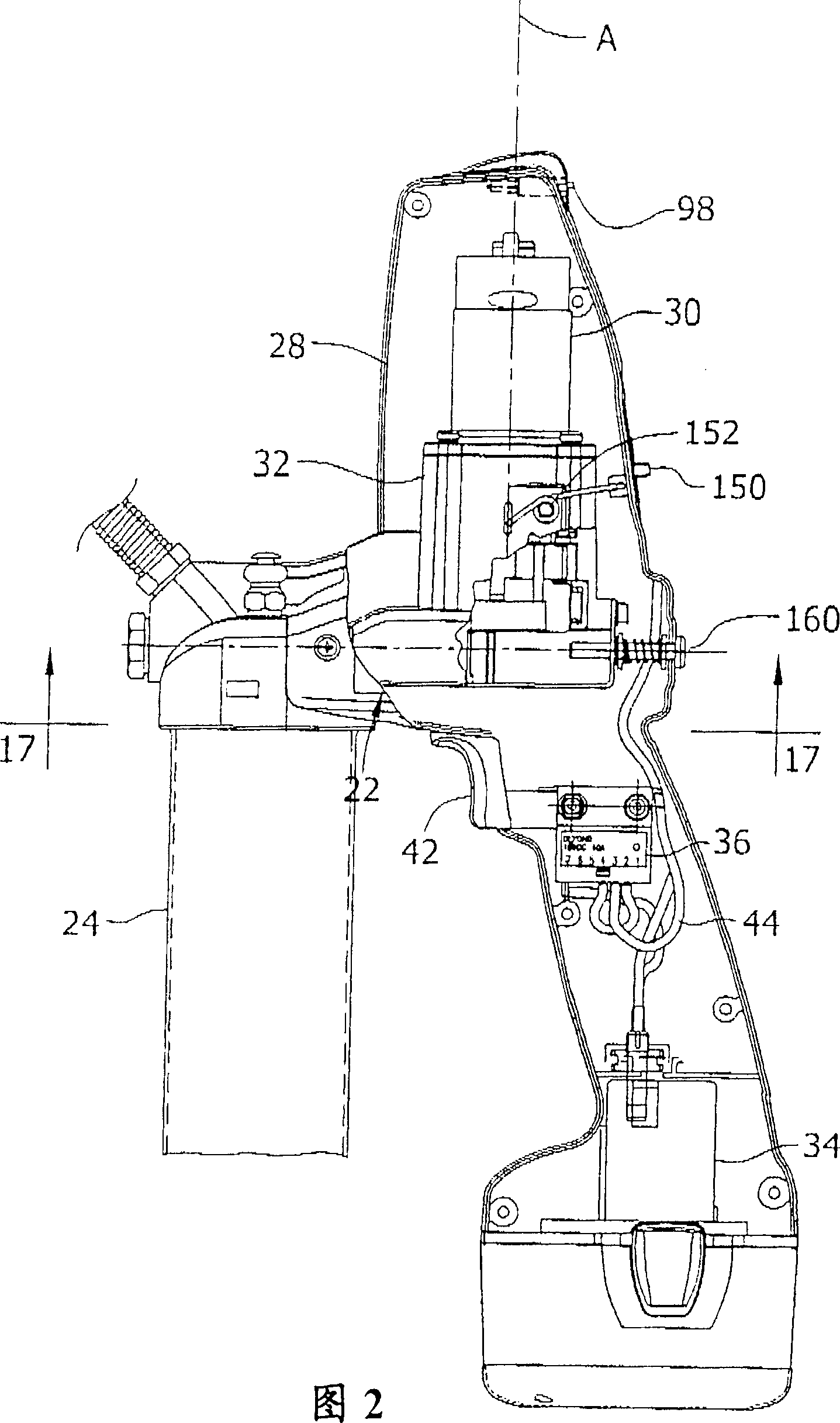

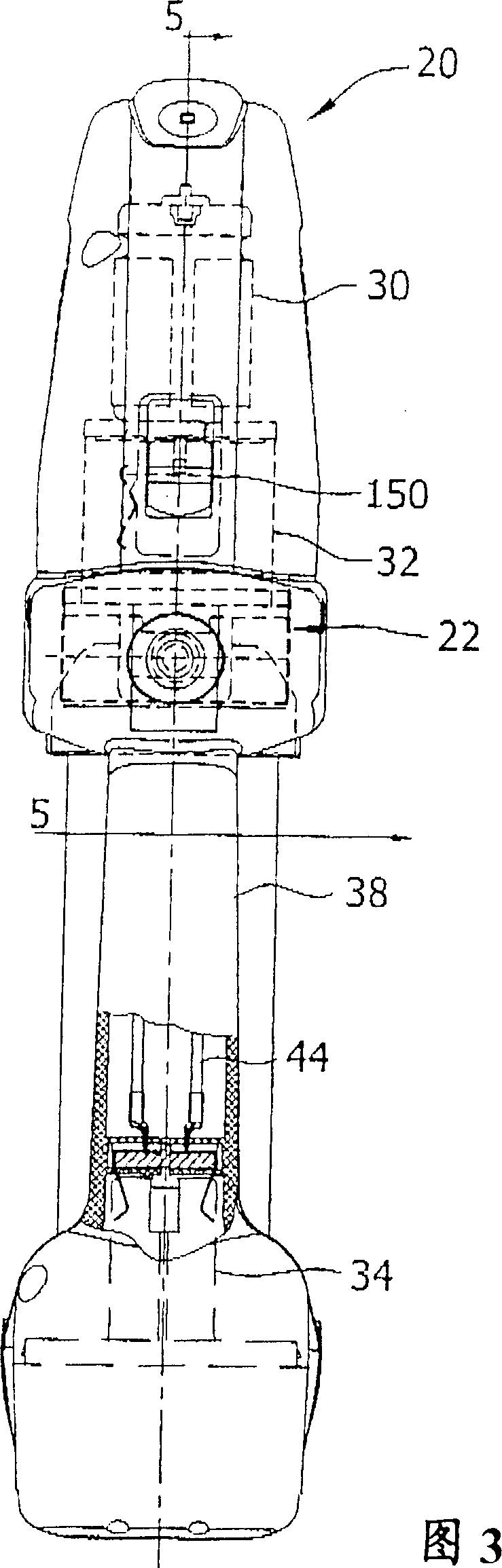

[0036]As shown in FIG. 2, the lubricant gun 20 has a housing 28 that accommodates the pump. Motor 30 and transmission assembly 32 are disposed within housing 28, generally above pump 22, while battery 34 and electrical switch 36 are disposed within housing, generally below the pump. In one embodiment, housing 28 has a clamshell construction made of molded plastic with two side halves held together by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com