Sparkle ball holding structure of connector

A connector and solder ball technology, applied in the direction of welding/welding connection, contact parts, etc., can solve the problems of warping and deformation of the circuit board, incomplete flatness, and the circuit board cannot be fully contacted, and achieve the effect of the best welding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

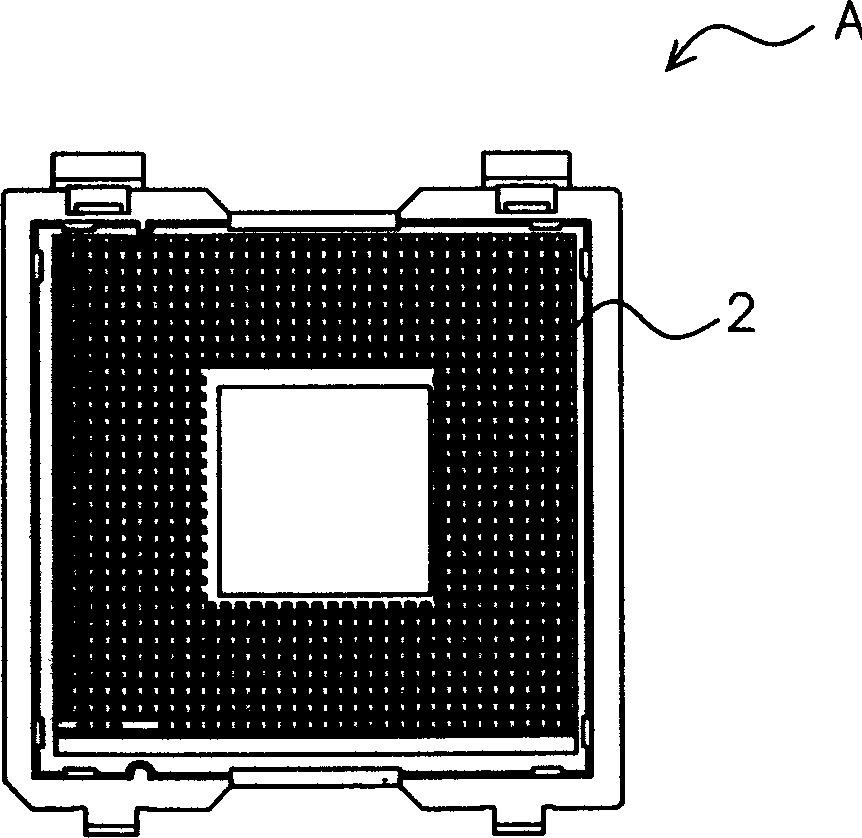

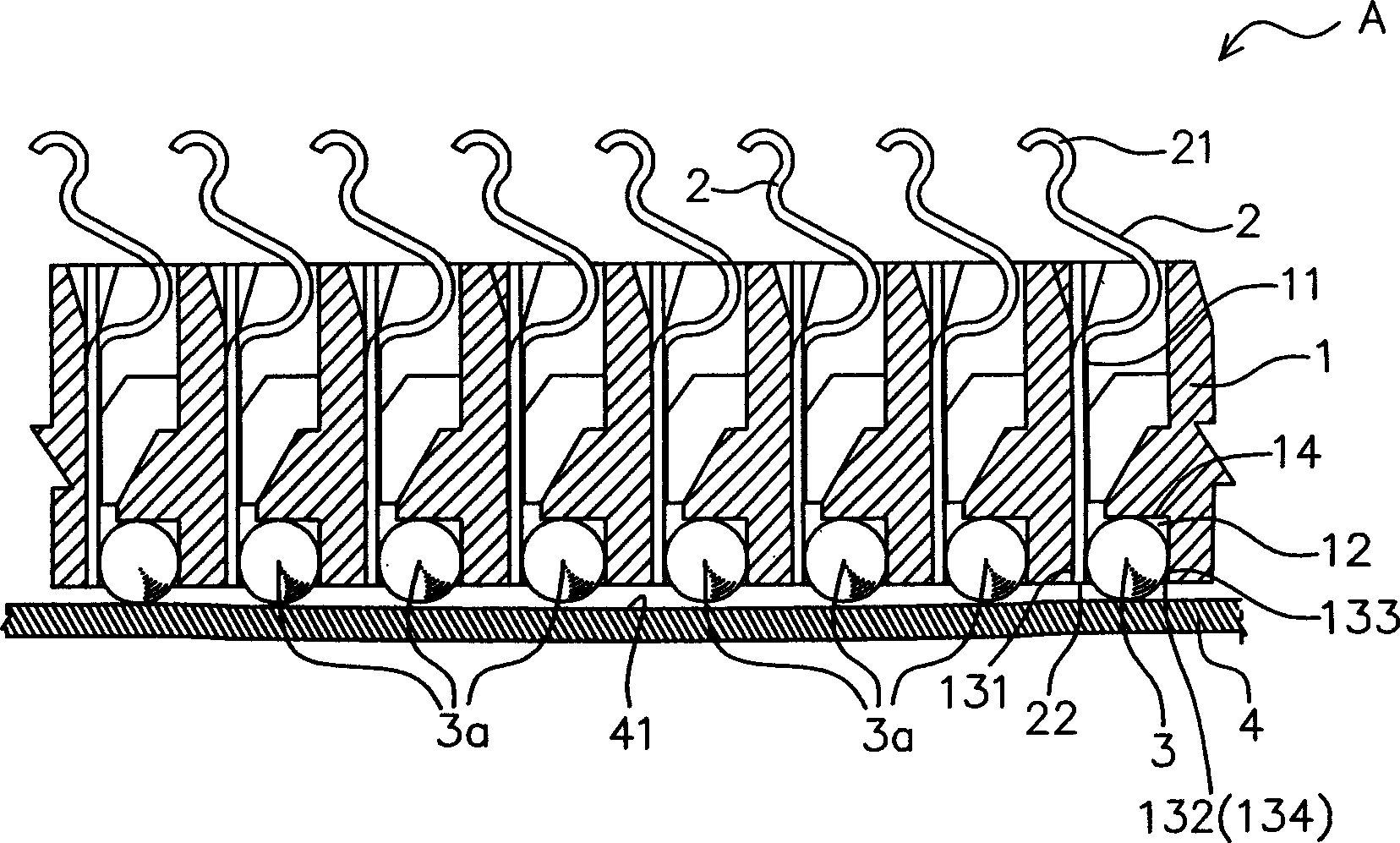

[0029] See attached Figure 5 to attach Figure 9 As shown: the connector B of the present invention still includes an insulating base body 1 , a plurality of terminals 2 , and a plurality of solder balls 3 .

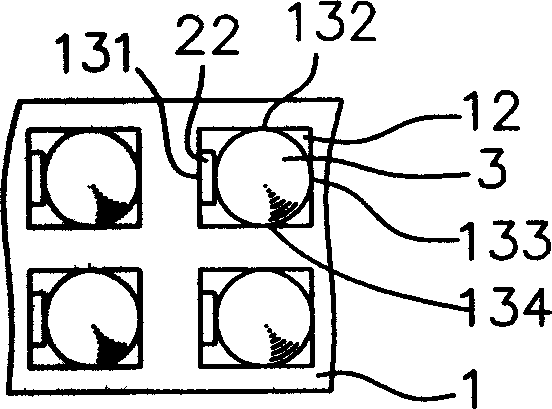

[0030] A plurality of terminal slots 11 penetrate through the insulating base body 1 along its vertical direction. Each terminal 2 is inserted into each terminal slot 11; the upper end and the lower end of these terminals 2 respectively form a contact portion 21 and a welding portion 22; The soldering portion 22 extends downward and protrudes from the bottom of the terminal slot 11 . A plurality of solder balls 3 in a circular state are placed between the insulating base 1 and each soldering portion 22 for soldering with the circuit board 4 .

[0031] The solder ball gripping structure of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com