Hydraulic pressure adjusting device

An adjustment device, hydraulic pressure technology, applied in the direction of transportation and packaging, brake components, control valves and air release valves, etc., can solve the problems of not shortening the braking distance, lengthening the braking distance, sacrificing the braking force, etc., to achieve good Anti-lock braking function, prevention of sideslip and tail flicking, shortening of braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

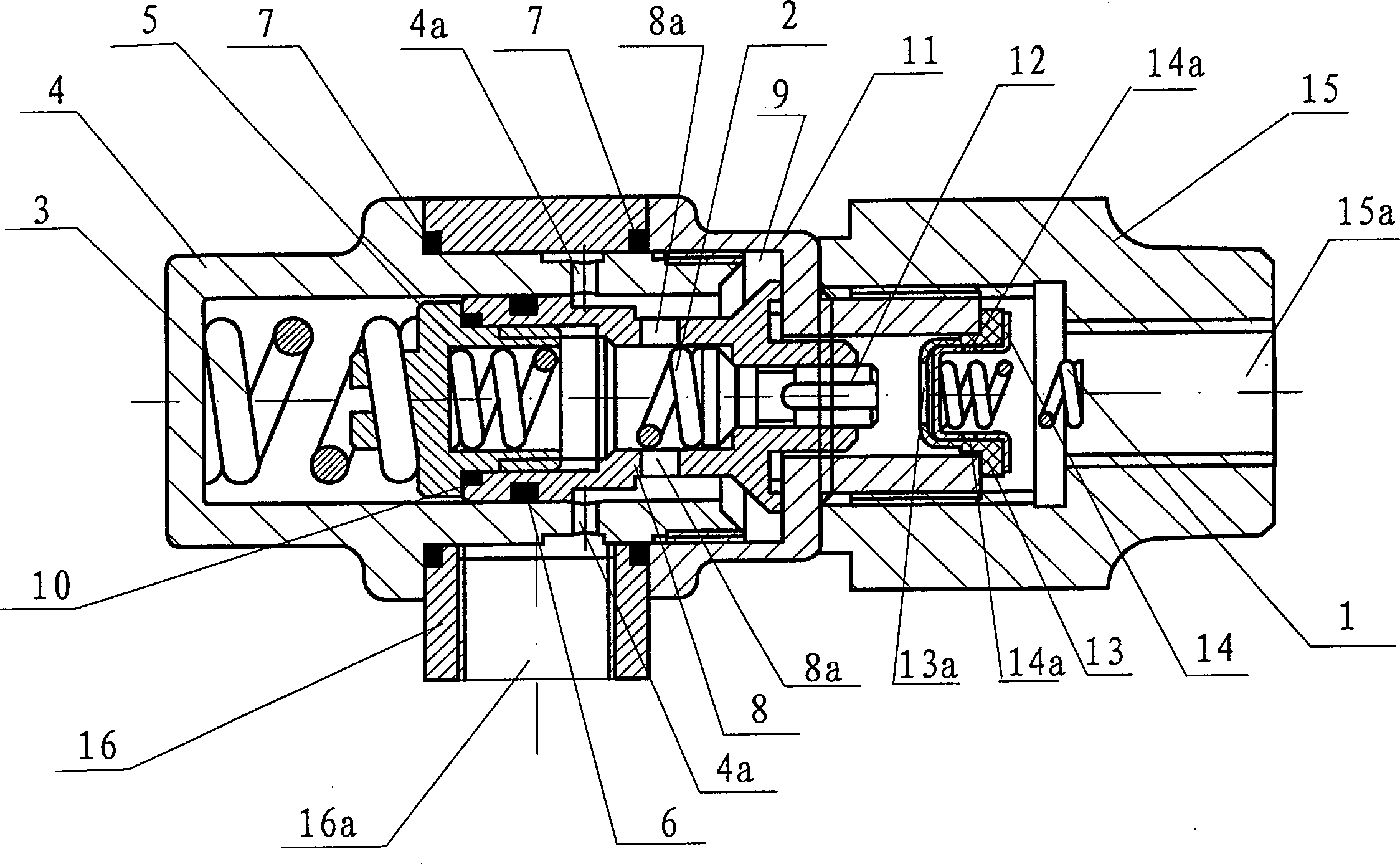

[0019] See figure 1 , The hydraulic pressure adjusting device of the present invention is characterized in that it includes a valve seat 4, a valve cover 11, an end cover 15, an adjusting ring 16, a pressure regulating valve 8, a check seat 14, a check cap 13, and a check valve 12. , The adjusting nut cover 5, the first spring 1, the second spring 2, the third spring 3; the valve seat 4, the valve cover 11, the end cover 15 are threaded in sequence to form an assembly cavity 9, which also serves as a brake The oil path of the oil; the pressure regulating valve 8 is placed on the connecting section of the valve seat 4 and the valve cover 11 of the assembly cavity 9; the check cap 13 is sleeved on the check seat 14 and placed in the assembly cavity 9 The connecting section of the valve cover 11 and the end cover 15, the top of the non-return cap 13 is provided with an oil through hole 13a, the circumference of the non-return seat 14 is provided with an oil through hole 14a; the adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com