Automatic-feeding metered-packing biscuit production process

A technology of measurement packaging and production process, which is applied to the improvement of biscuit measurement packaging technology and the field of biscuit automatic feeding measurement packaging production technology, which can solve the problems that biscuits cannot be automatically docked with packaging machines, reduce labor intensity, etc., and achieve automatic flow operation , reduce labor intensity, and reduce biscuit pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the application examples shown in the accompanying drawings.

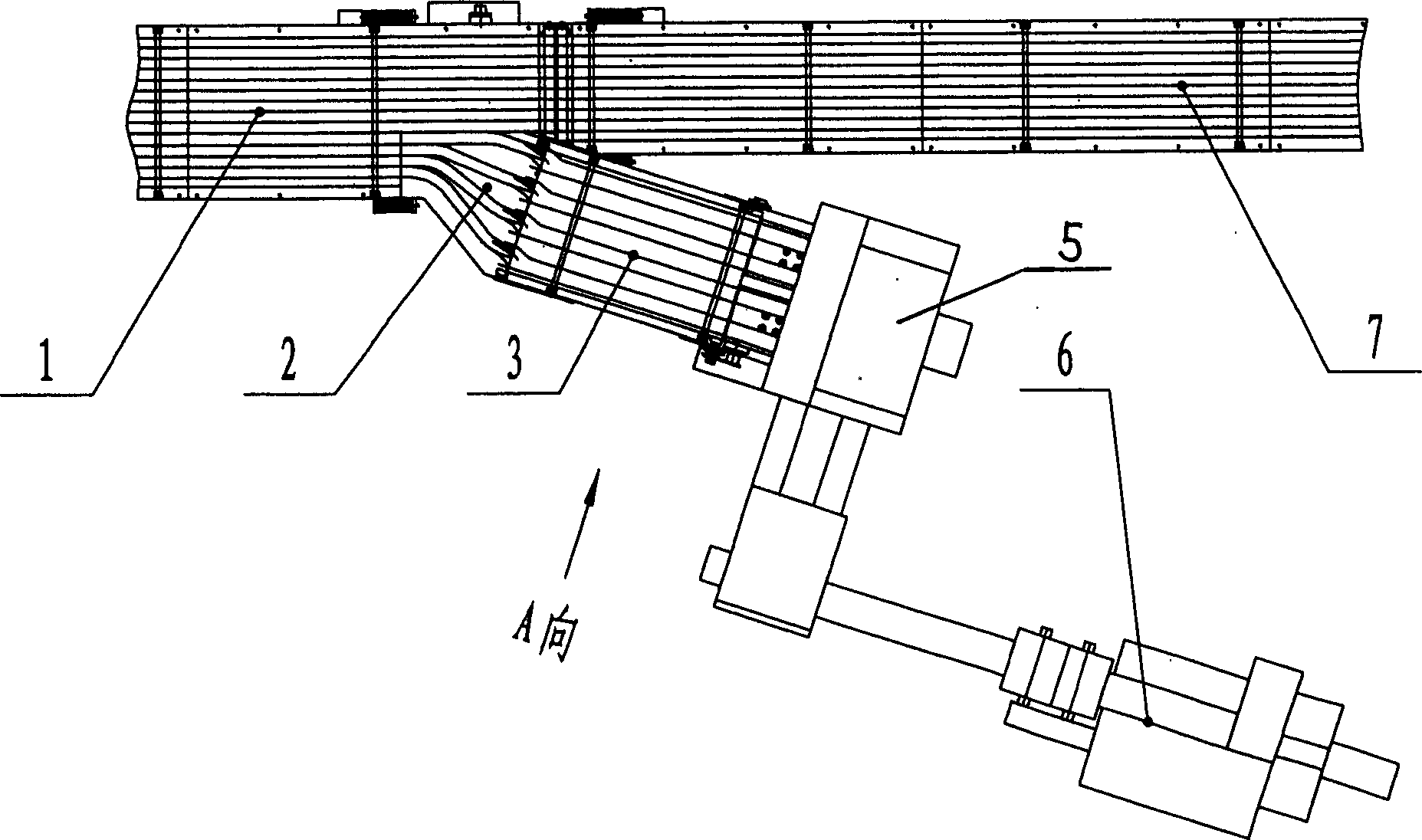

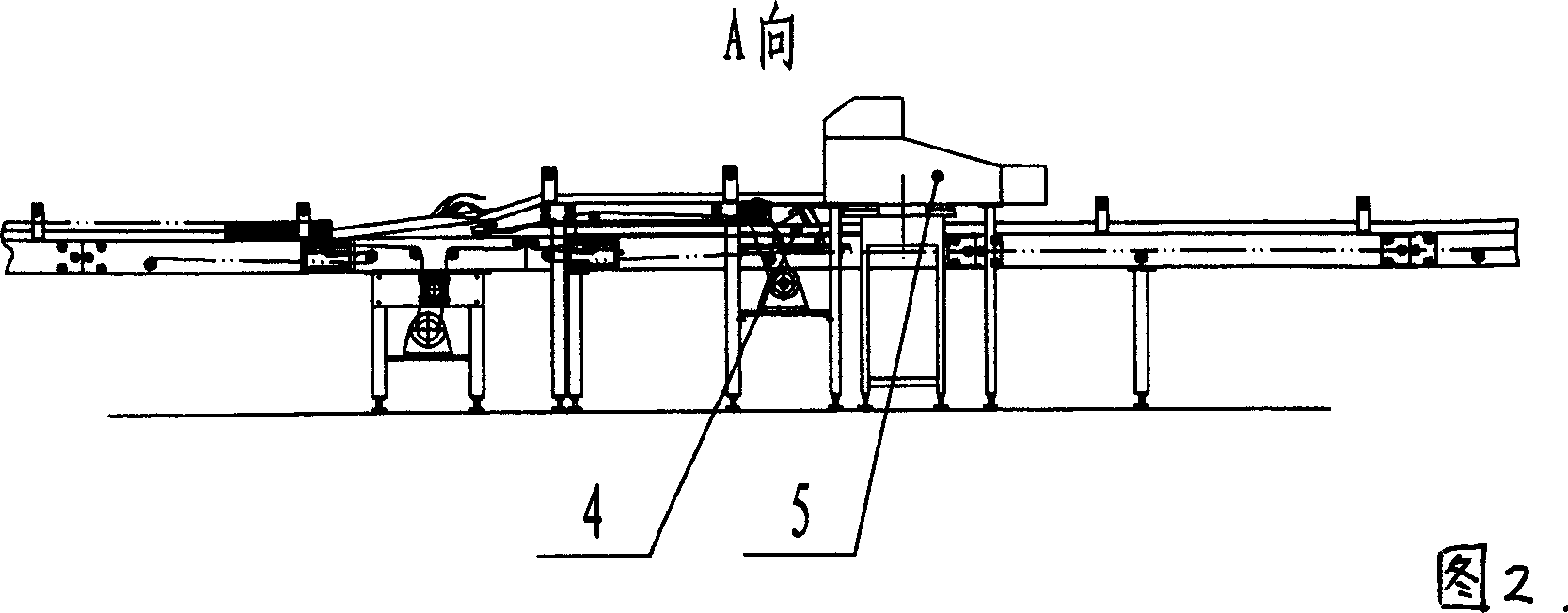

[0018] The overall plan for the biscuit automatic feeding metering and packaging production process is: each set of automatic metering feeding device 5 feeds a biscuit packaging machine 6, and each time it feeds the packaging machine 6 2-6 times, biscuit packaging The packaging speed of the machine 6 is linked with the feeding speed of the biscuit automatic feeding metering packaging feeding system, and the biscuit packaging machine 6 and the biscuit automatic feeding metering packaging feeding system are configured according to the output of the production line.

[0019] The main components of the production line formed by implementing the process of the present invention are composed of 7 parts, which are respectively: 1, the main conveyor belt; 2, the biscuit 90 ° turning mechanism; 3, the biscuit feeding conveyor belt; 5. Biscuit a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com