Translating unit of deposit type conveyor

A technology of accumulative conveyors and translation devices, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increased project cost, low degree of automation, and large space occupation, so as to reduce project cost and automate High degree, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

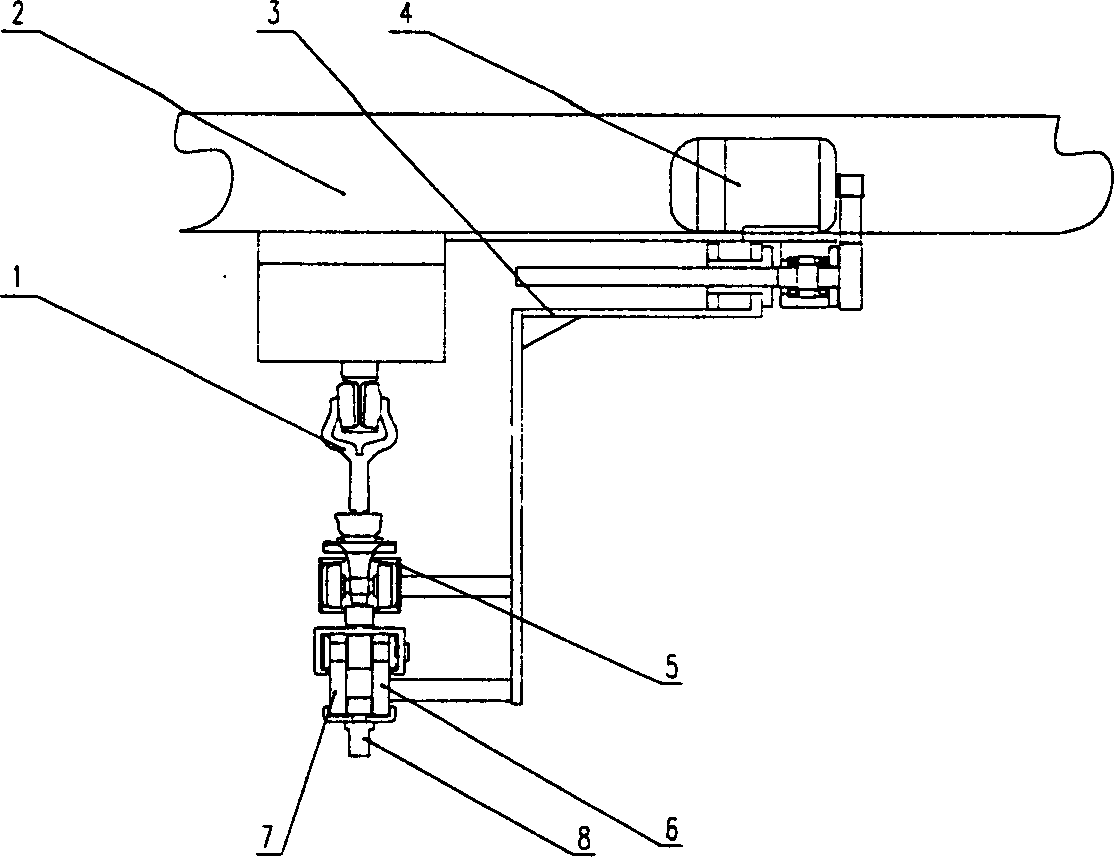

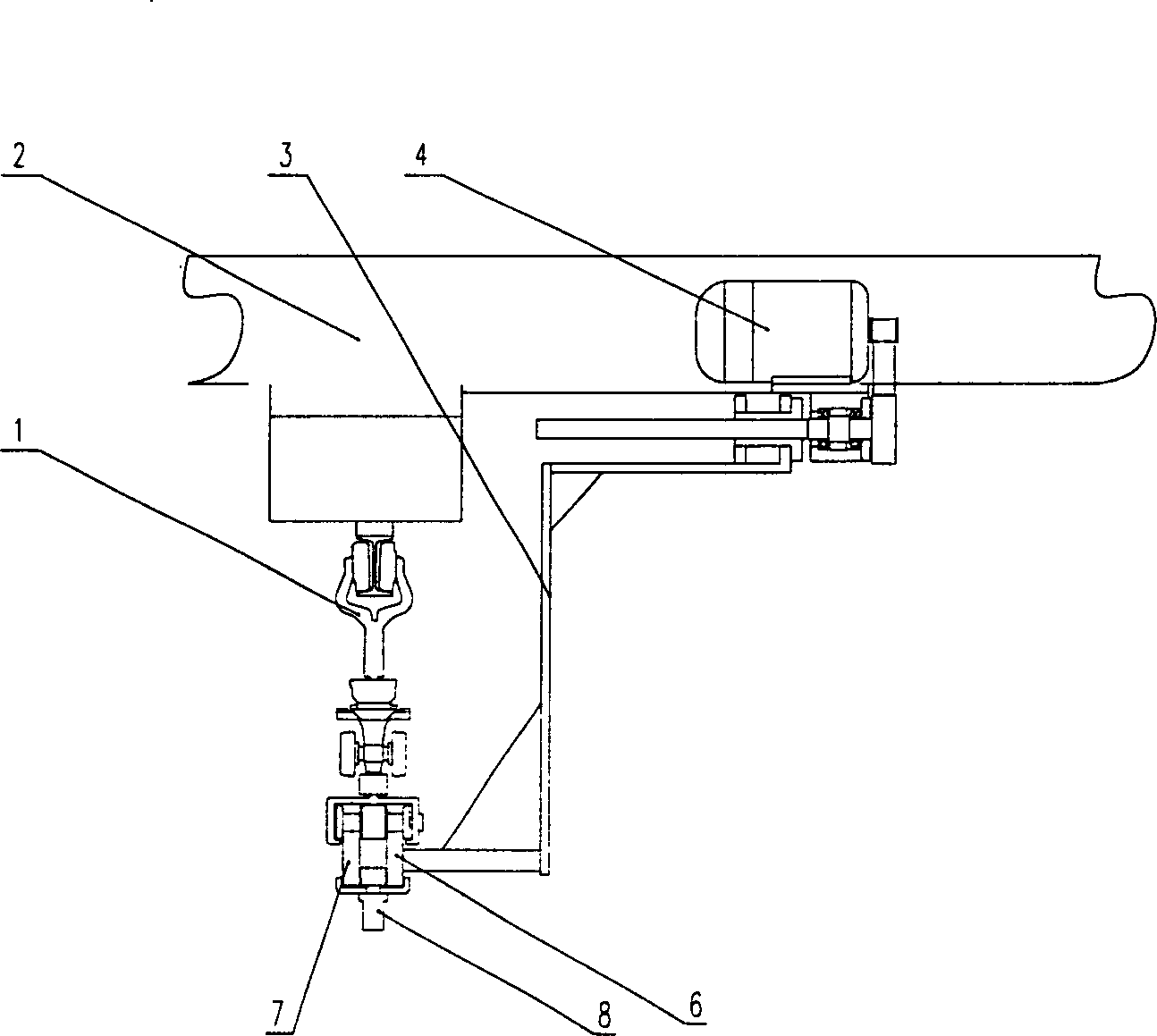

[0008] Referring to the accompanying drawings, the driving device 4 of the translation mechanism is fixed on the steel structure auxiliary beam 2 of the accumulation type conveyor 1 where the double-carrying rails and the double-sided single-carrying rails are mutually converted. The translation rail 6 in the rail is fixed on the movable plate 3 of the translation mechanism at the same time (or there is no double bearing rail in the translation place, and the translation rail 6 in the double-sided single bearing rail is fixed on the movable plate 3 of the translation mechanism), and the accumulating trolley 8 is on the double bearing rail The accumulative and free conveyor 1 interchangeable with the double-sided single-carrying rail can move or be fixed on the translation rail 6 in the double-sided single-carrying rail. Between the translation mechanism driving device 4 and the translation mechanism movable plate 3, a group of screw nuts (or cylinders, guide rails, or rack and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com