Cleaning apparatus for air cooling unit

A technology for cleaning devices and air-cooling units, which is applied to cleaning heat transfer devices, cleaning methods using liquids, and non-rotating equipment cleaning. It can solve the problems of high labor intensity and inconvenient operation for workers, and achieve good cleaning effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

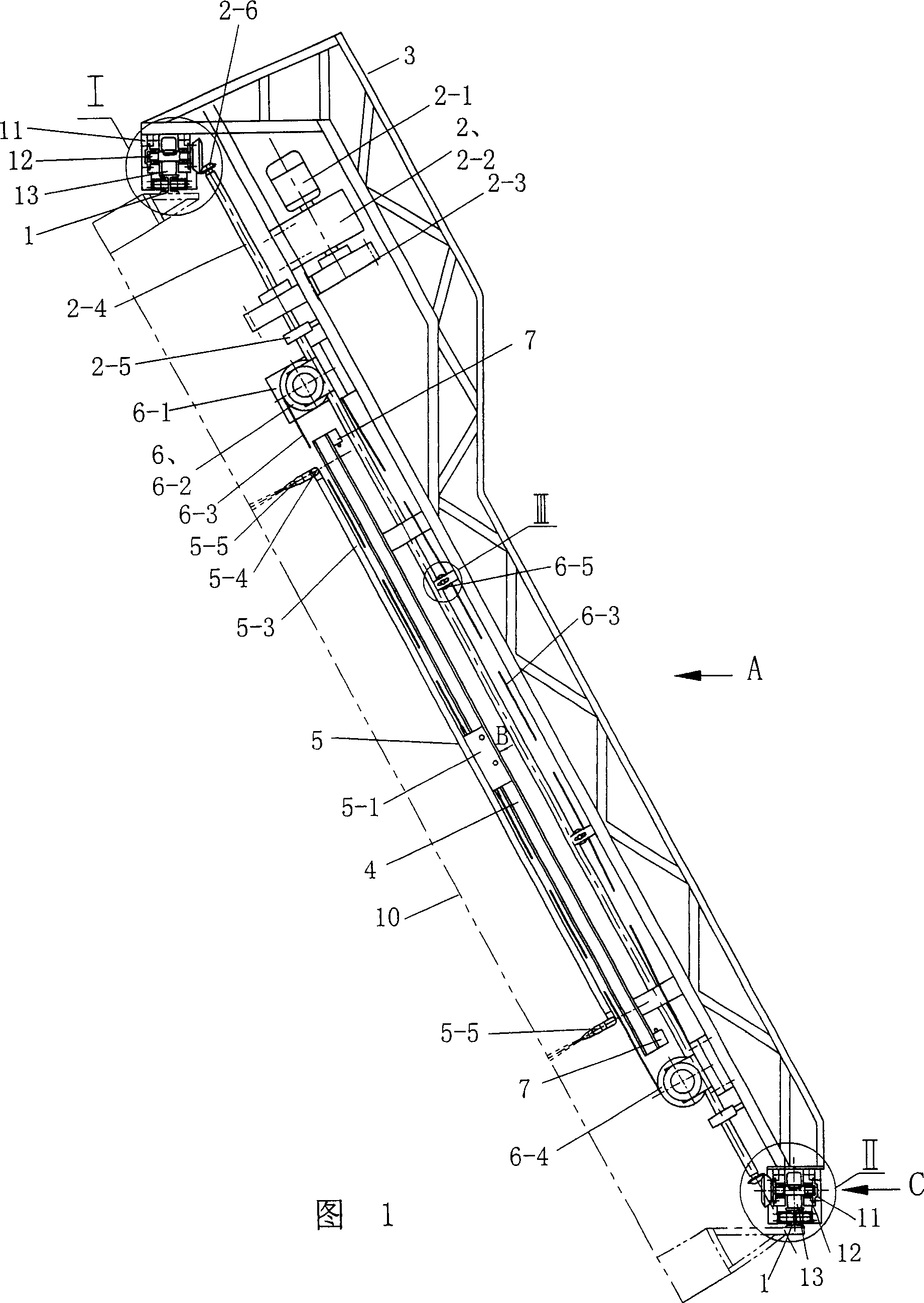

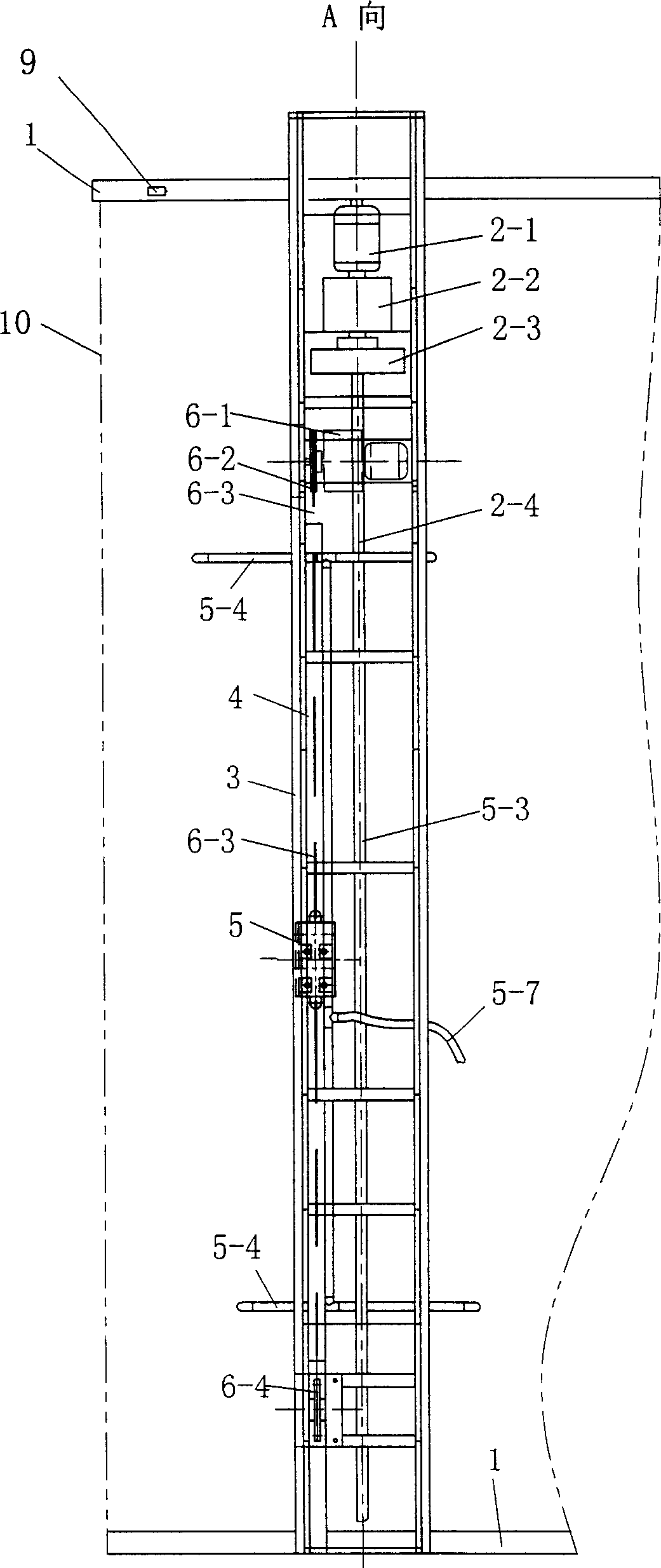

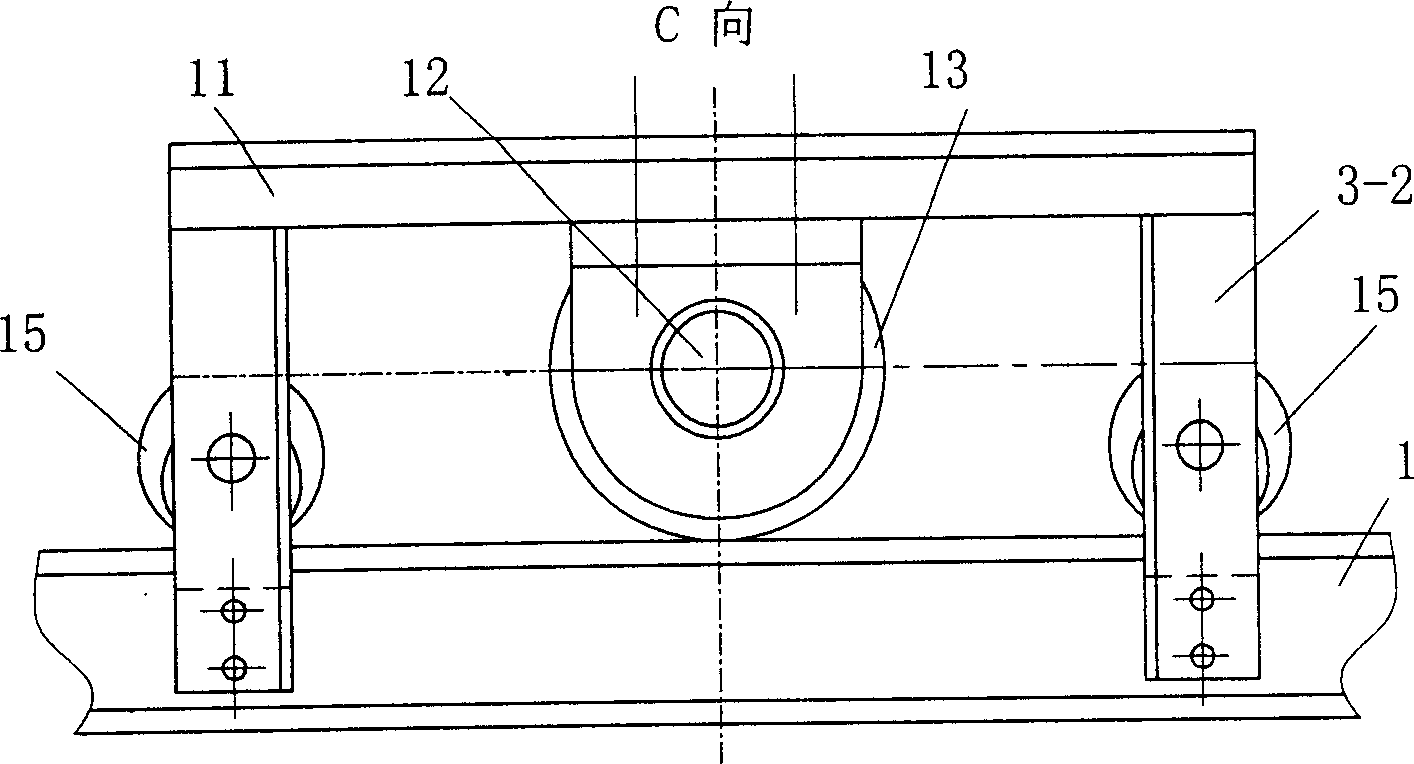

[0034] See Fig. 1~5, present embodiment has upper and lower transverse guide rail 1, and upper and lower transverse guide rail 1 adopts I-beam. The upper and lower transverse guide rails are installed parallel to the radiator 10. A mobile frame 3 is arranged between the transverse guide rails 1, and the upper and lower ends of the mobile frame 3 are respectively provided with a wheel seat 11, and the upper and lower wheel seats 11 are respectively connected to the roller shaft 12 by a bearing 12-1, and the roller shaft 12 is fixed with a roller 13. The rollers 13 on the upper and lower wheel bases 11 are equal in diameter and placed on the upper and lower transverse guide rails 1 respectively, rolling on the top surfaces of the upper and lower transverse guide rails. The upper and lower two wheel bases 11 are respectively provided with anti-side wheels 15 (see image 3 ), the axle of anti-side wheel 15 is to be fixed on the wheel base 11 and be connected by bearing between an...

Embodiment 2

[0043] See Fig. 16, 17, if there is still a section of distance that water can not be sprayed between the nozzle 5-5 on the upper lateral branch pipe of the nozzle assembly and the top of the cooling fin, an upwardly protruding lateral additional water pipe8. The additional water pipe 8 is provided with 3 shower nozzles 8-1, and the additional water pipe 8 is connected with the water pump through the flexible pipe 8-2. The part is cleaned by the water ejected from the shower head 8-1 by the movement of the moving frame 3. The above-mentioned additional water pipe nozzle 8-1 is a linear nozzle. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com