Concavo-convex gear type rotor engine

A rotary engine and gear-type technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of insufficient combustion of the mixture, poor sealing performance of the cylinder block, low fuel efficiency, etc., and achieve complete combustion and work Smooth, uniform output power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: A twin-cylinder engine composed of 8 concave tooth rotors and 6 convex tooth rotors

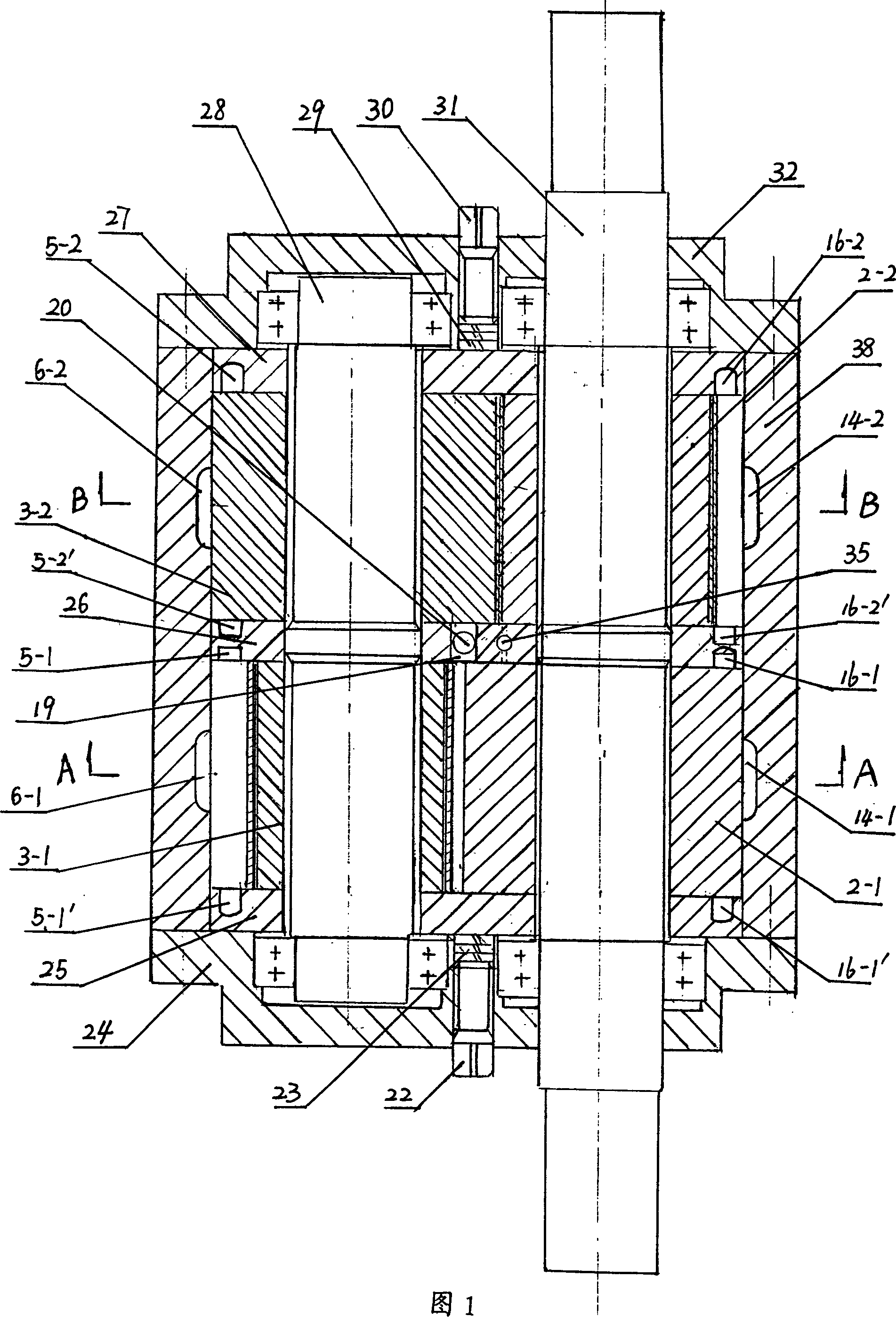

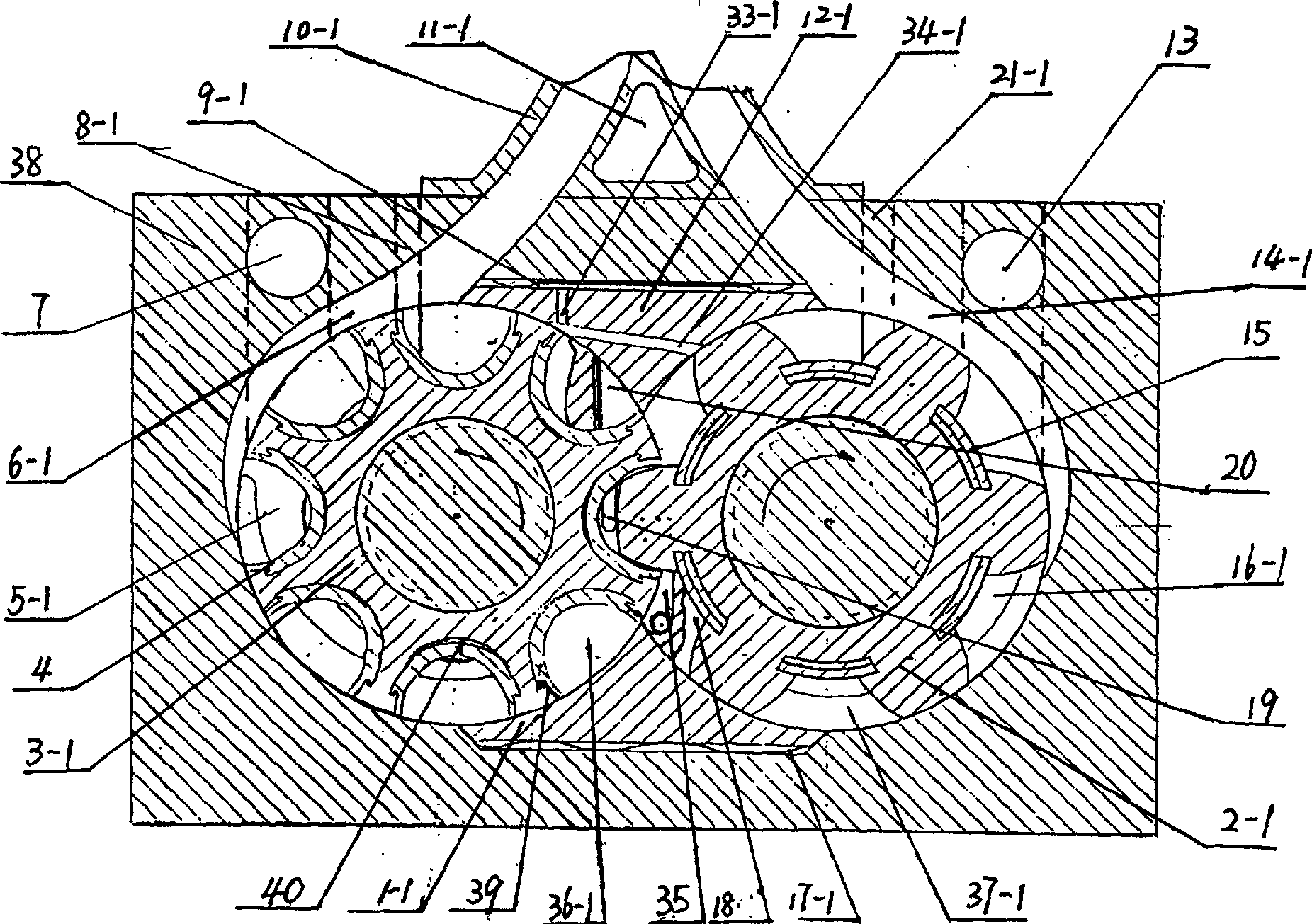

[0036] Fig. 1 is the cross-sectional view of the double-cylinder convex-concave gear rotor engine of the present invention, the two ends of cylinder body 38 are respectively provided with outer end caps 24,32, are respectively provided with inner end caps 25,27 inside two outer end caps, cylinder body A main shaft 28 and an auxiliary shaft 31 are arranged inside, and a back pressure spring 23 is fixed by an adjustment bolt 22 at the joint between the outer end cover and the inner end cover between the main shaft and the auxiliary shaft, and a back pressure spring 29 is fixed by an adjustment bolt 30 . The inside of the cylinder body is divided into two cavities A and B with the same structure by the middle partition 26, and the middle partition, the inner end cover and the back pressure spring realize axial sealing. figure 2It is the A-A sectional view of cylinder A. In cyli...

Embodiment 2

[0045] Embodiment 2 is a four-cylinder engine composed of 8 concave-toothed rotors and 6-convex-toothed rotors with two cylinders for power and two cylinders for compression. The structure and working process of the two cylinders in the middle are basically the same as those in Embodiment 1, and a Press the cylinder.

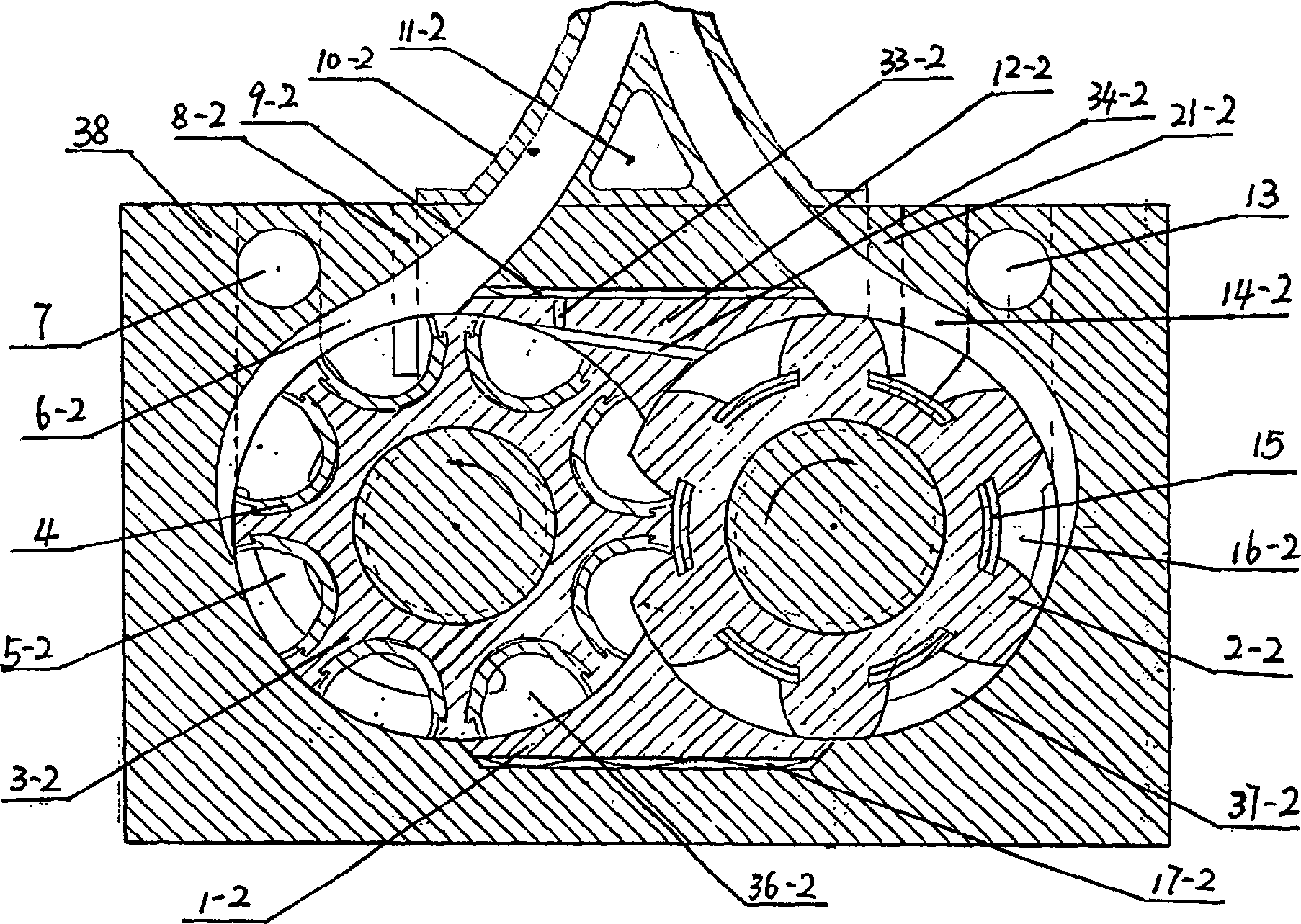

[0046] Figure 5 It is a cross-sectional view of a four-cylinder convex-concave gear rotor engine. Outer end covers 24 and 32 are respectively arranged at both ends of the cylinder body 38, inner end covers 25 and 27 are respectively arranged inside the two outer end covers, and a main shaft is arranged in the cylinder body. 28 and auxiliary shaft 31, the outer end cover between the main shaft and the auxiliary shaft and the inner end cover joint are fixed with back pressure spring 23 by adjusting bolt 22, and are fixed with back pressure spring 29 by adjusting bolt 30. The inside of the cylinder body is divided into four cavities A2 cylinder, A1 cylinder, B1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com