Deep water mooring system combining float and weight block

A gravity block and combined technology, applied in the fields of deep water mooring and deep water mooring systems, can solve the problems of difficult dynamic characteristics of cables and fatigue damage of synthetic cables, and achieve the effect of reducing construction difficulty, reducing project cost and enhancing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

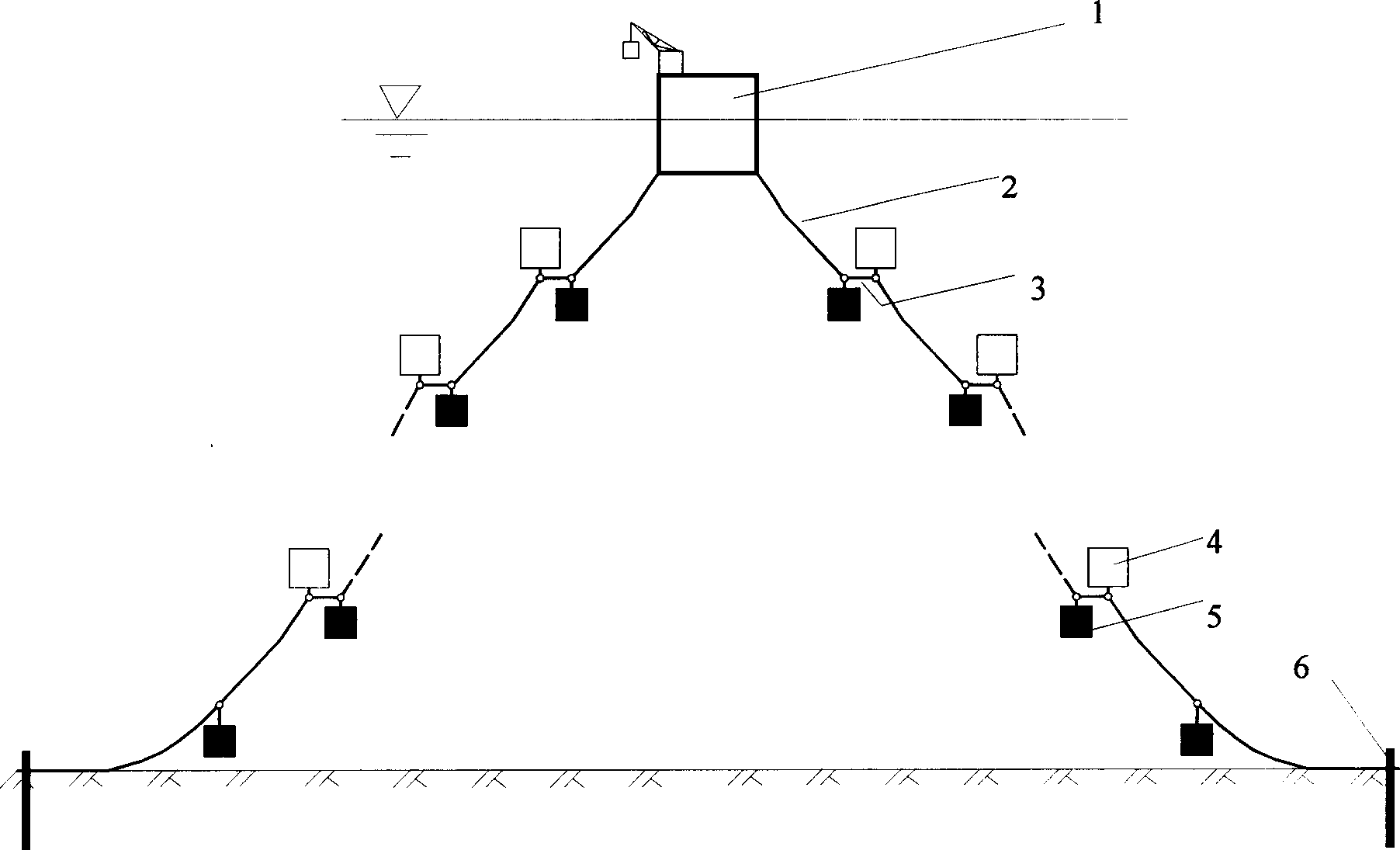

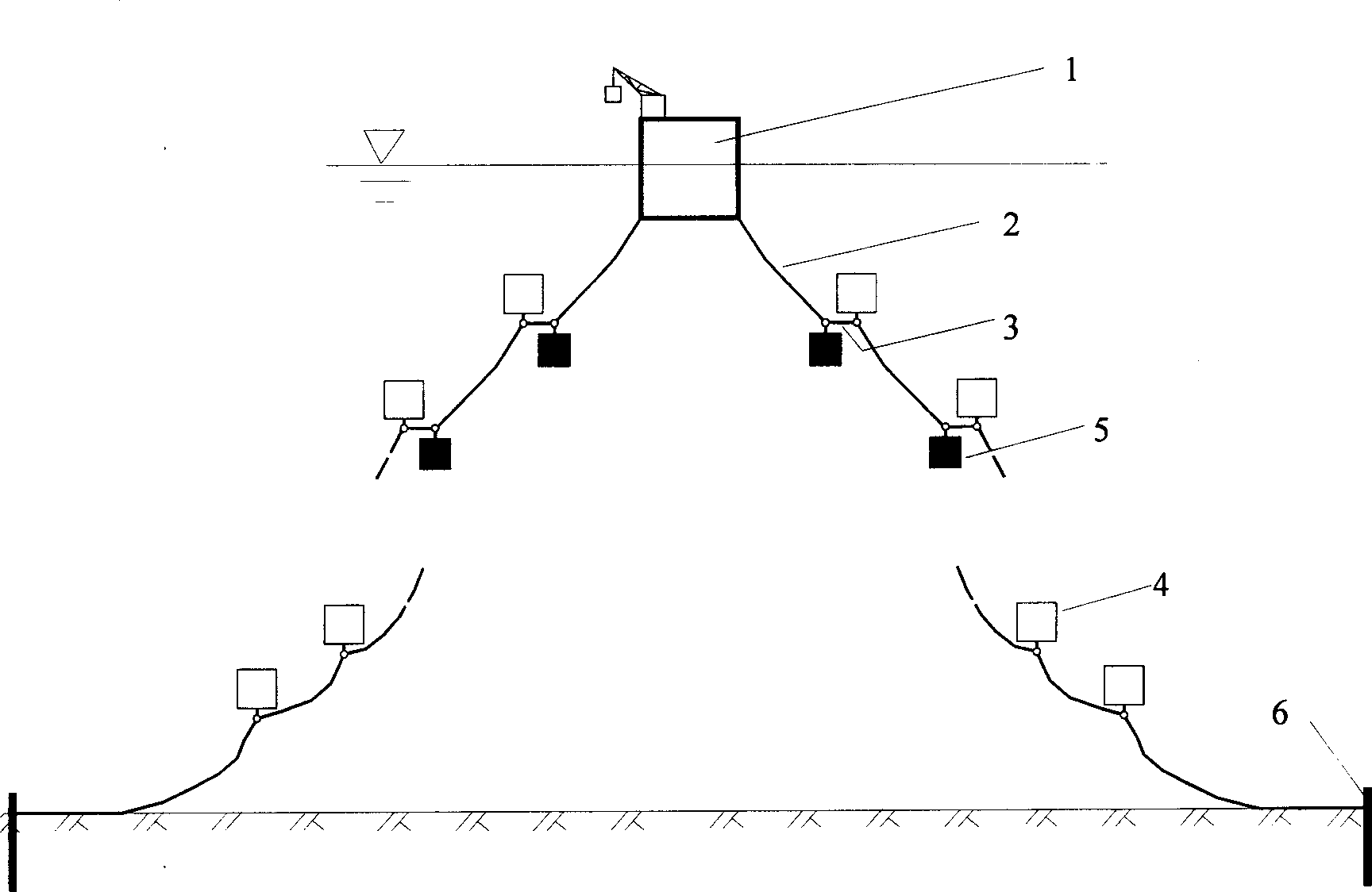

[0017] The claim of the present invention includes any use of floating bodies and gravity blocks to change the angle between the anchor chain or anchor cable section and the horizontal plane, increase the horizontal stiffness of the anchor chain or anchor cable, change the natural vibration frequency of the mooring system, and increase system damping. The buoyant and gravity block pair mode can be used in all or part of a mooring system. Application of the present invention can effectively equate deep-water moorings into several shallow-water moorings. Wherein the weight of the gravity block can be changed from zero to arbitrarily large, and the buoyancy of the floating body can also be arbitrarily changed as required. Two examples (but not limited thereto) are given below to illustrate the implementation method of the present invention.

[0018] Example 1: Set up a mooring system at a water depth of 2,000 meters, with a total of 12 anchor cables. Each anchor cable is design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com