Roadway stacker and complete goods storage rollaway stand

A technology of stacker and roadway, which is applied in the field of cargo storage raceways, can solve the problems of wasting storage space, inability to store goods, and ineffective use of space, and achieve the goal of utilizing space, utilizing space, and facilitating transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

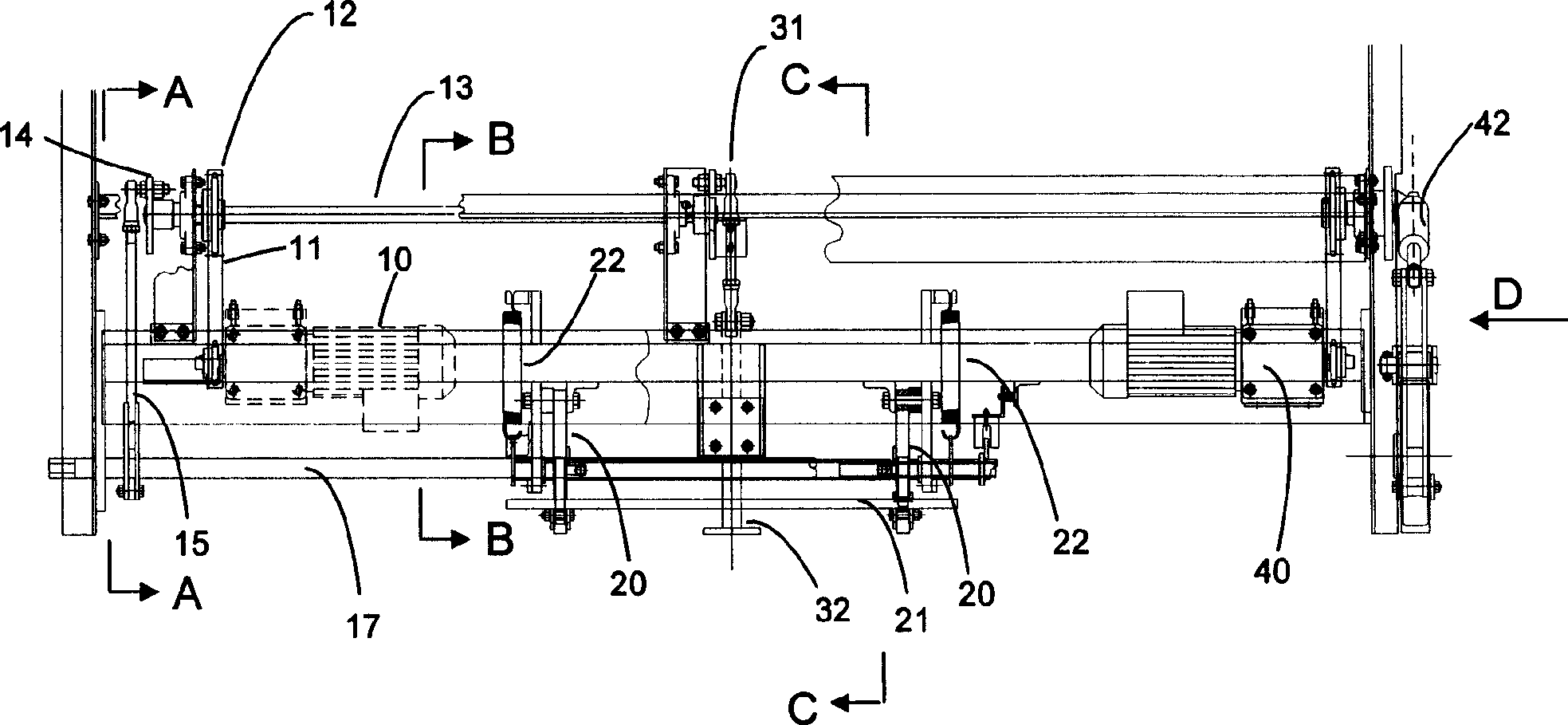

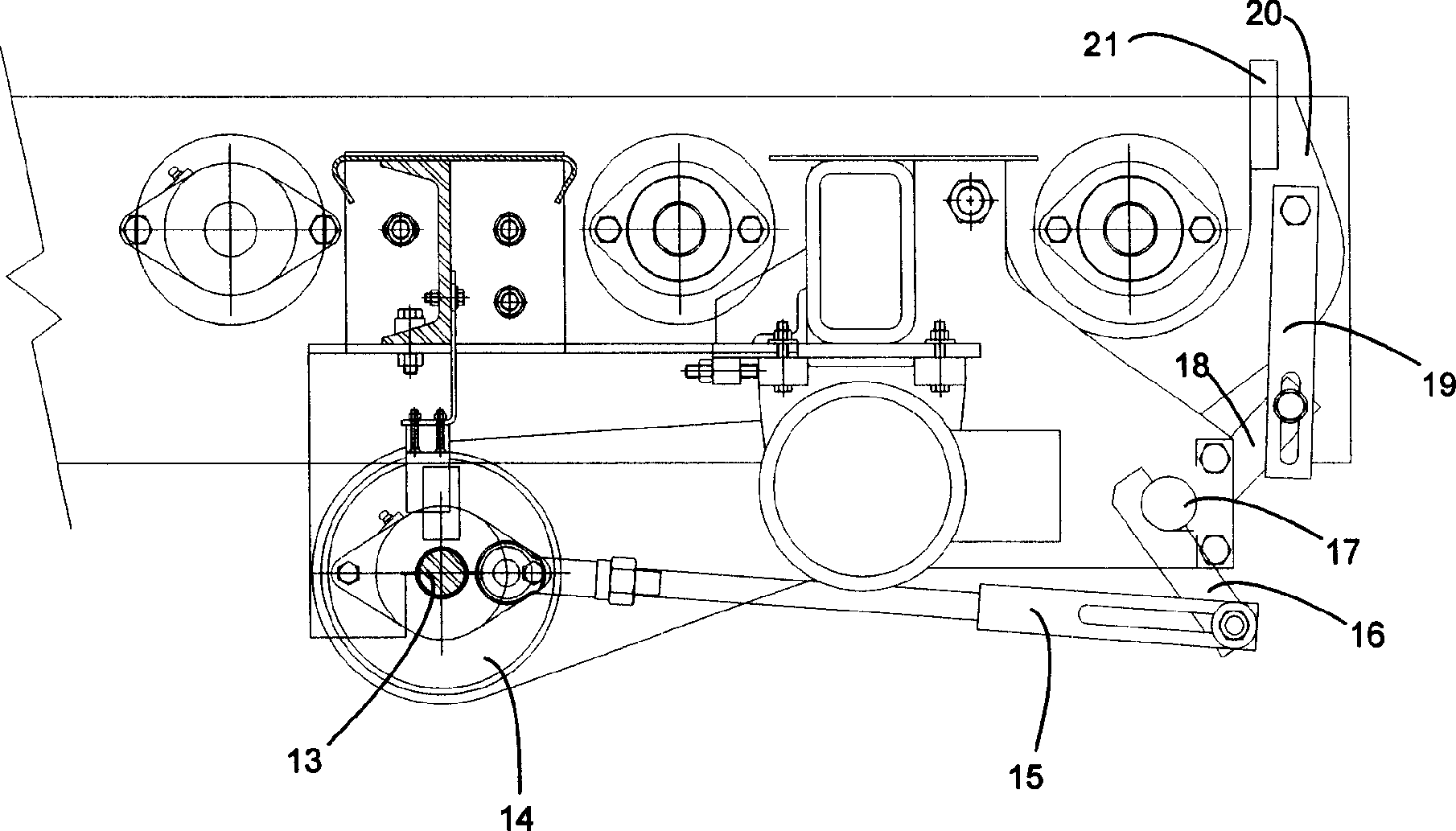

[0018] refer to figure 1 with figure 2 , a motor 10 is provided under the workbench of the roadway stacker, and the sprocket 12 is connected through the chain 11. On the outside, the other end is provided with an elongated hole, which is movably connected with one end of the rod 16 by a bolt, and the other end of the rod 16 is arranged on the rotating shaft 17 . The baffle plate 21 is arranged on two symmetrical arc brackets 20, and the arc bracket 20 can rotate around the shaft between the two rollers. One side of the arc bracket 20 is connected with movable rods 18 and 19, and the rod 18 is hinged. on the shaft 17.

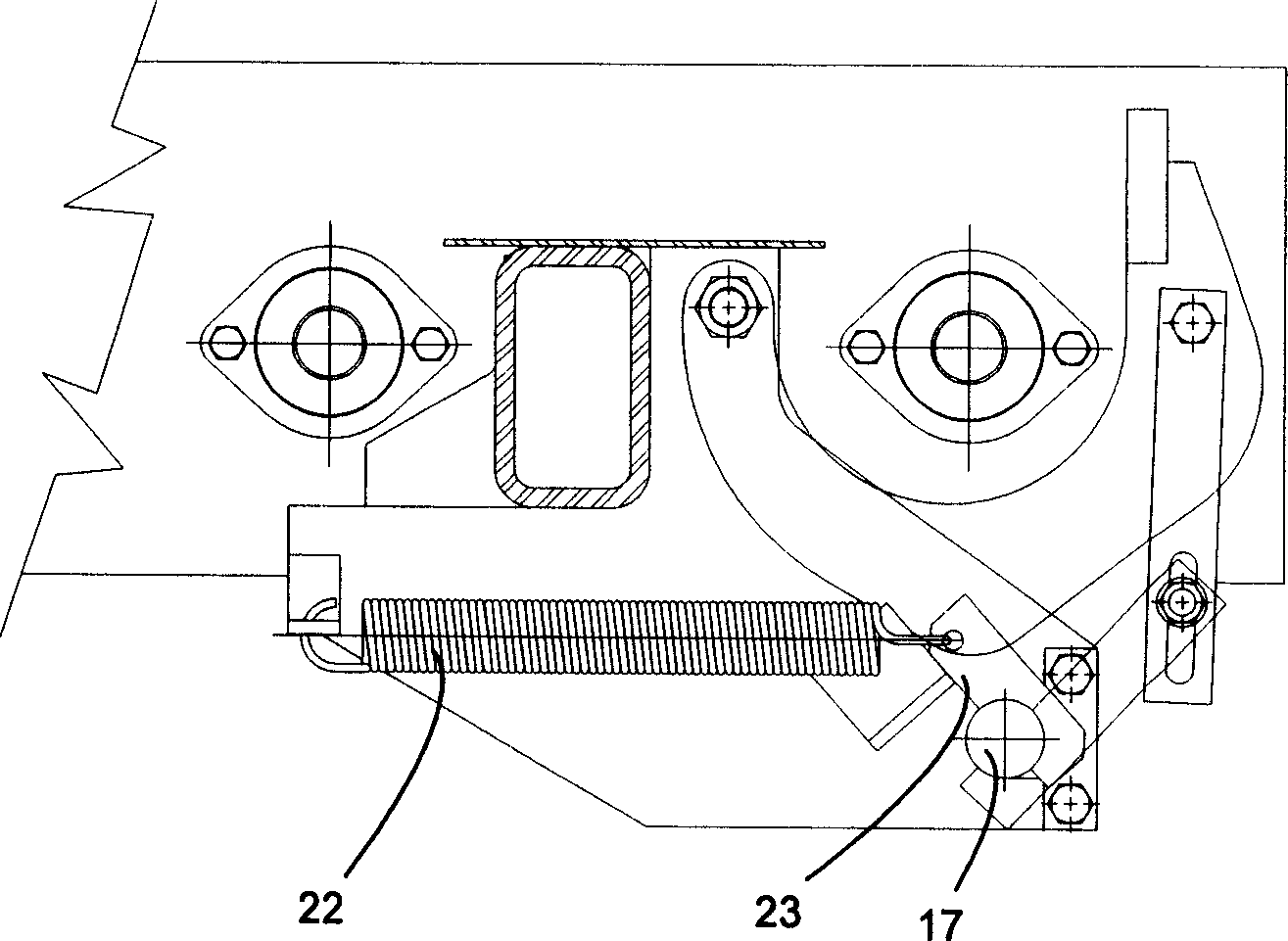

[0019] refer to figure 1 with image 3 , the central position of rotating shaft 17 is symmetrically provided with spring 22, and one end of spring 22 is fixed on the support, and the other end links to each other with bent bar 23 one end, and bent bar 23 other ends are fixedly connected with rotating shaft 17.

[0020] refer to figure 1 with Figure 4 A ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap