Cold water soluble polymer microparticles and method for their preparation

一种水溶性聚合物、聚合物的技术,应用在化学仪器和方法、具有旋转搅拌装置的混合机、溶解等方向,能够解决相容性变差、环境和卫生问题、不能用等问题,达到良好水湿润性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The method for preparing cold water-soluble polymer particles according to the present invention includes fluidizing water-soluble polymer particles while dropping or spraying or mixing liquid or powder containing a wetting agent into the polymer particles.

[0017] The water-soluble polymer microparticles used in the present invention include powder or microparticles of water-soluble cellulose ethers, such as methylcellulose, hydroxyethylcellulose, hydroxypropylmethylcellulose, hydroxyethylmethylcellulose, hydroxy Ethyl ethyl cellulose, hydroxyethyl hydroxypropyl cellulose, hydroxypropyl cellulose, hydroxybutyl cellulose, carboxymethyl cellulose, etc., sodium polyacrylate, polyethylene oxide and its derivatives, poly vinyl alcohol etc.

[0018] In the present invention, the wetting agent adheres and spreads to form a thin film on the surface of each water-soluble polymer particle, whereby the surface part of each water-soluble polymer particle is easily dissolved in co...

Embodiment 1

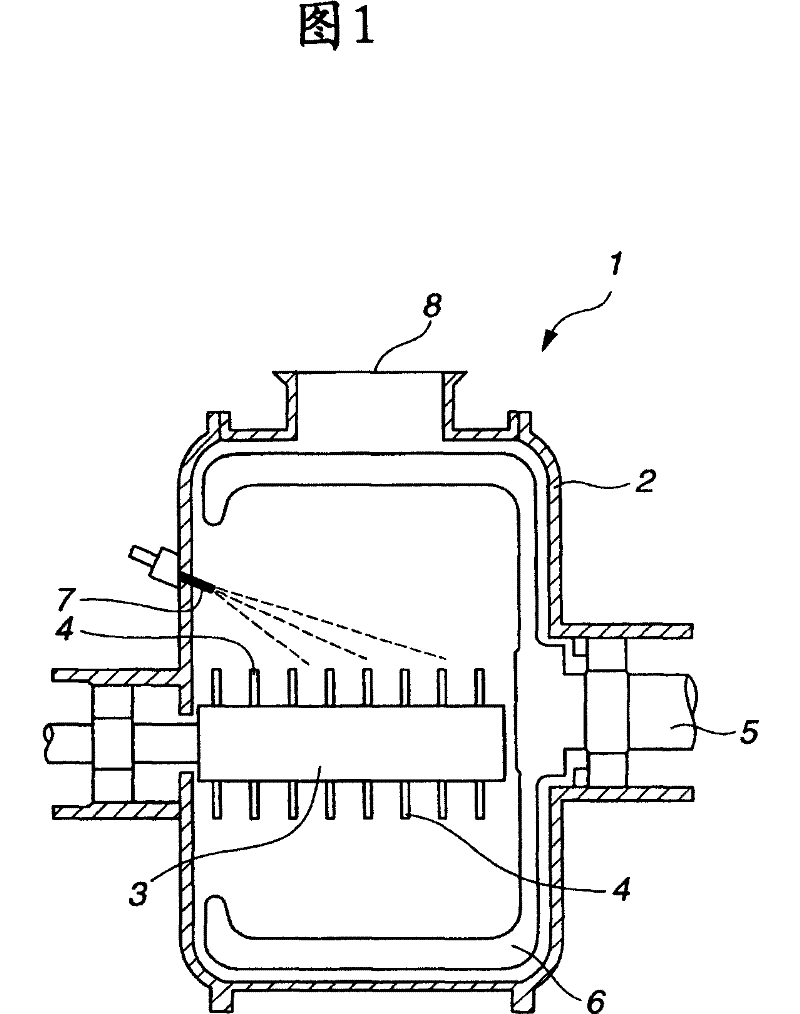

[0041] 0.5 kg of hydroxypropylmethylcellulose (trade name Metolose 60SH-10000, manufactured by Shin-Etsu Chemical Co., Ltd.) powder (not passing through the No. 30 sieve described in Japanese Pharmacopoeia 14th Edition B-1061 (opening of 500 μm) is 0%, the percentage by weight of the powder passing through No.140 sieve (opening of 106 μm) is 82%, and the average particle diameter is 64 μm) added to Dalton Co., Ltd. RMO-2H Spartan-Ryuzer mixing granulator equipment (stirrer equipment) (effective capacity is 2L), such as figure 1 As shown, it has a stirring rotating blade connected to a first rotating shaft horizontally rotating in the middle part of the stirring container and a belt-shaped stirring blade connected around the stirring rotating blade and rotating in the opposite direction. The rotation speed of the rotary blade was 4700 rpm, and the ribbon stirring blade was rotated around the rotary blade at a speed of 25 rpm in the opposite direction, so that the powder could b...

Embodiment 2

[0045] The experiment was repeated in the same steps as in Example 1, except that the hydroxypropylmethylcellulose powder used in Example 1 was replaced by hydroxypropylcellulose M manufactured by Nippon Soda Co., Ltd., and 0.25 g of NOF Corporation manufactured The sorbitan monocaprylate (trade name: Ceramisol C08) was used as a wetting agent, and dispersed with 10 g of water to improve the cold water solubility.

[0046] Sieve in the same manner as in Example 1 to obtain a water-soluble polymer powder, wherein the percentage by weight of the powder capable of passing through the No.140 sieve (opening of 106 μm) described in Japanese Pharmacopoeia 14th Edition B-1061 is 66%, The average particle diameter is 72 μm. The powder thus obtained was measured for the time required for its dissolution in the same manner as in Example 1, and the results showed that the dissolution time was within 30 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com