A kind of preparation method of iron trench castable containing graphene oxide

A technology of iron trench castables and graphene, which is applied in the field of iron trench castables, can solve the problems of difficult dispersion of graphite, inapplicability to large-scale production, and reduced strength of samples, so as to improve structural strength and corrosion resistance, and reduce structural stress. Peeling and cracking, porosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

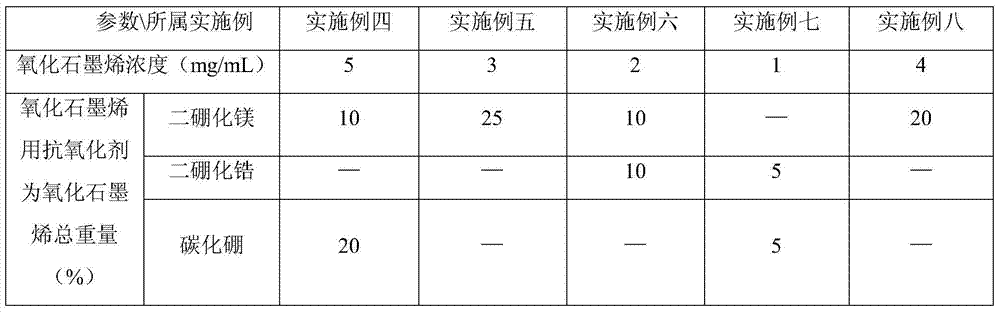

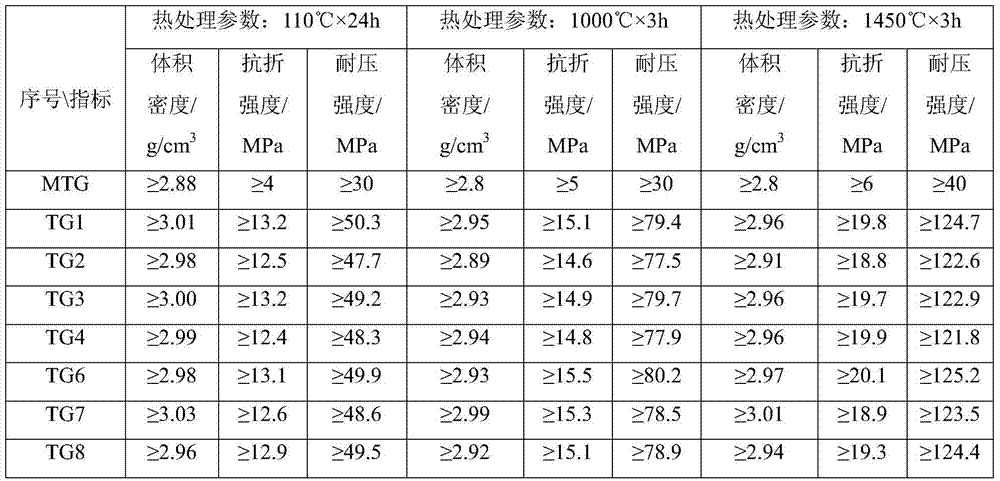

Examples

Embodiment 1

[0034] A kind of preparation method of iron channel castable containing graphene oxide, add by weight percentage by 43% dense corundum, 20% white corundum, 20% silicon carbide, 7% α-Al 2 o 3 Micropowder, 3% silica powder, 3% aluminate cement, 2% spherical asphalt and 2% elemental silica fume are used as raw materials, adding 0.1% water reducer and 0.1% of the total weight of the raw materials The auxiliary material that the anti-explosion fiber of above-mentioned raw material gross weight 0.05% is formed, adds graphene oxide solution and graphene oxide antioxidant (the consumption of graphene oxide in graphene oxide solution is described raw material gross weight 0.05%, the graphene oxide solution The concentration is 3 mg / mL, and the amount of antioxidant for graphene oxide is 20% of the amount of graphene oxide).

[0035] The antioxidant for graphene oxide is magnesium diboride, and the water reducer is sodium tripolyphosphate.

[0036] The mass content of aluminum oxide i...

Embodiment 2

[0044] A preparation method of iron trench castable containing graphene oxide, adding 50% dense corundum, 10% white corundum, 15% silicon carbide, 10% α-Al in weight percentage 2 o 3 Micropowder, 5% silicon dioxide micropowder, 5% aluminate cement, 3% spherical asphalt, 2% elemental silicon powder are used as raw materials, and 0.5% of the water reducer and 0.5% of the total weight of the raw materials are added. The auxiliary material that the above-mentioned raw material gross weight 0.2% explosion-proof fiber constitutes, adds the graphene oxide that accounts for described raw material gross weight 0.01% and the graphene oxide antioxidant of described graphene oxide consumption 10-30%, adds raw raw material gross weight 3 % water.

[0045] The antioxidant for graphene oxide is zirconium diboride, and the water reducer is sodium polyacrylate.

[0046] The above-mentioned graphene oxide was added as a graphene oxide solution with a concentration of 5 mg / mL. The preparation...

Embodiment 3

[0053] A preparation method of iron trench castable containing graphene oxide, adding 30% dense corundum, 30% white corundum, 30% silicon carbide, 3% α-Al in weight percentage 2 o 3 Micropowder, 1% silica micropowder, 4% aluminate cement, 1% spherical asphalt, 1% elemental silicon powder are used as raw materials, and 0.5% of the total weight of the raw materials is added to the water reducer and the raw materials 0.1% of the total weight of explosion-proof fiber constitutes auxiliary materials, adding 0.1% of the total weight of the raw material graphene oxide and 10% of the graphene oxide antioxidant, adding 1% of the total weight of the raw material water.

[0054] The antioxidant for graphene oxide is boron carbide, and the water reducer is sodium hexametaphosphate.

[0055] The above-mentioned graphene oxide was added as a graphene oxide solution with a concentration of 1 mg / mL. The preparation method of the graphene oxide solution refers to Example 1.

[0056] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com