Aluminum alloy material with excellent surface stability and method for manufacturing the same

An aluminum alloy material and stability technology, which is applied in metal material coating process, superimposed layer plating, coating, etc., can solve the problems of excellent surface stability and inability to obtain surface characteristics over time, and achieve surface stability Excellent performance, reduced maintenance frequency, and good water wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

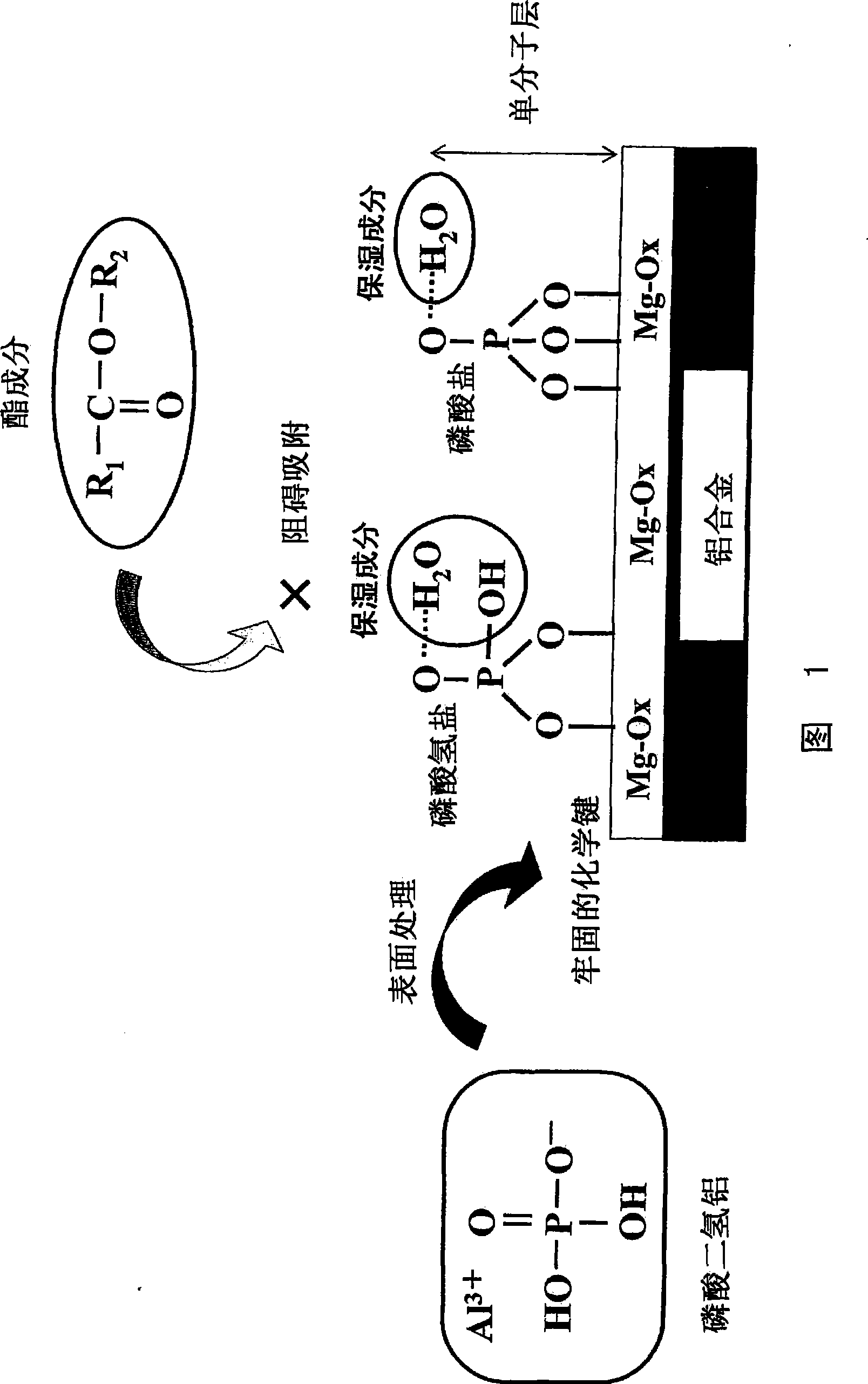

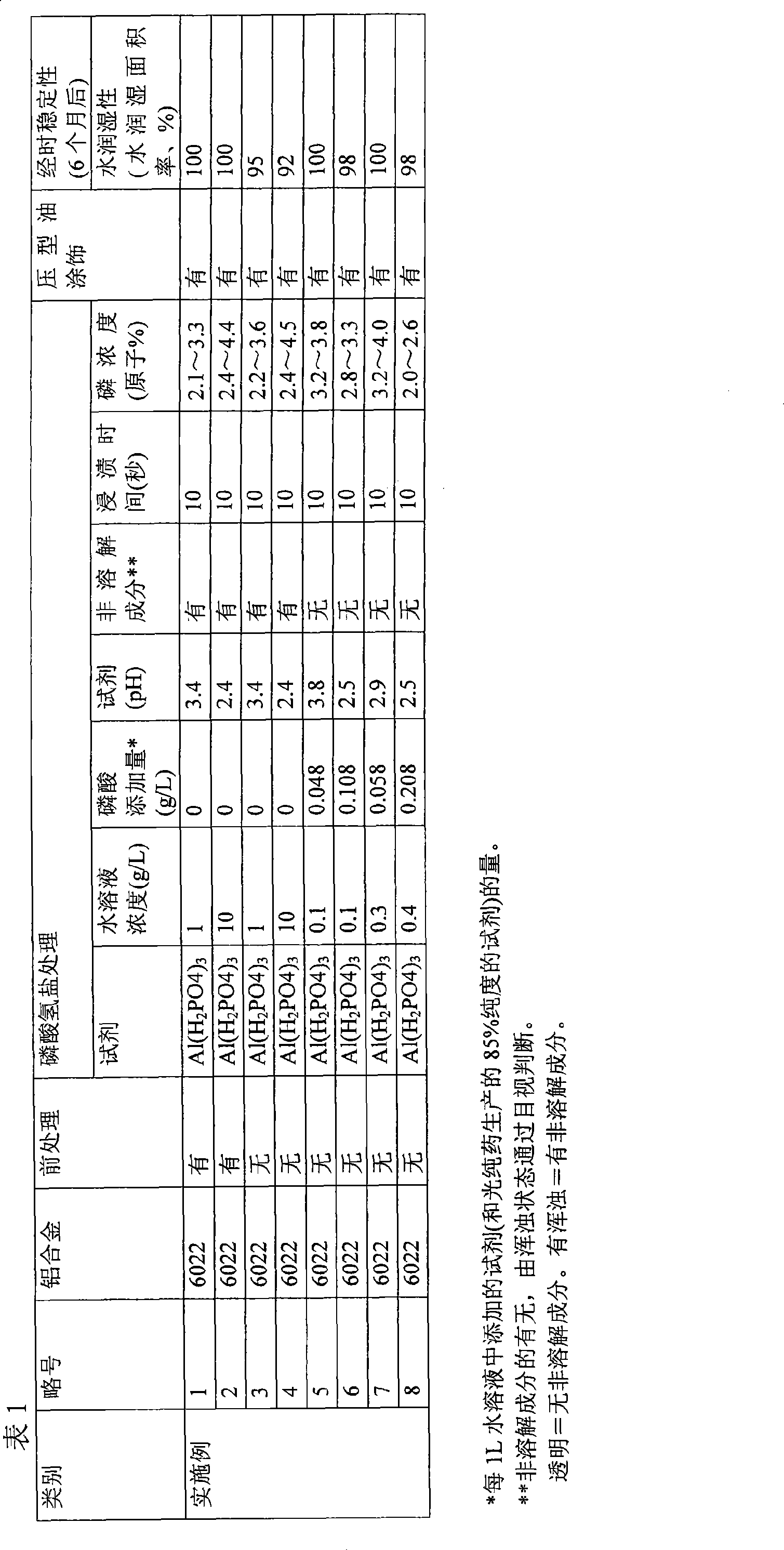

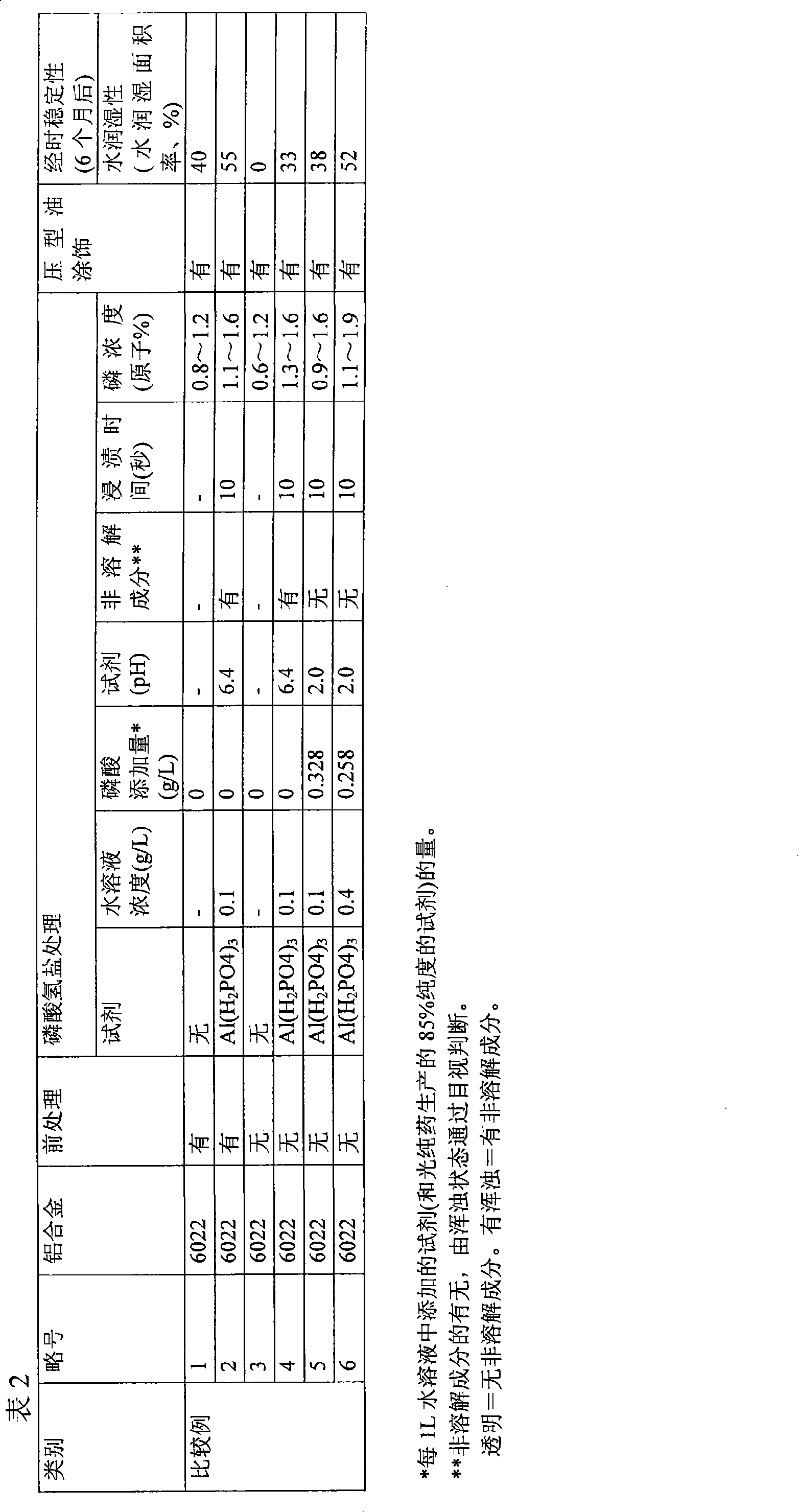

[0055] Examples of the present invention are described below. A 6022-standard aluminum alloy cold-rolled plate (thickness 1mm) of the 6000 series, a test piece with a length of 70 mm and a width of 150 mm was used. This 6022 aluminum alloy plate contains Mg: 0.55%, Si: 0.95%, and 0.2% has a resistance of 230MPa.

[0056] When performing pretreatment before phosphate treatment, immerse in a commercially available weakly alkaline degreasing solution at 60 to 90°C for 1 to 10 seconds or after spraying, then immerse in 1 to 20 mass% nitric acid or sulfuric acid at 50 to 90°C for 1 ~10 seconds or spray, then rinse with water.

[0057] By adopting the above pretreatment conditions, the aluminum oxide film or magnesium already formed on the surface of the test piece can be removed. However, since an aluminum oxide film is rapidly formed on the surface of the test piece, the hydrated phosphate attached to the surface of the test piece by the hydrogen phosphate treatment exists or is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com