A kind of composite material of nanocellulose/fiber fabric and preparation method thereof

A nanocellulose and fiber fabric technology, applied in plant fibers, fiber processing, textiles and papermaking, etc., can solve the problems of insufficient mechanical strength of the base material, difficult to further disperse, limited application fields, etc. The effect of tensile strength improvement and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

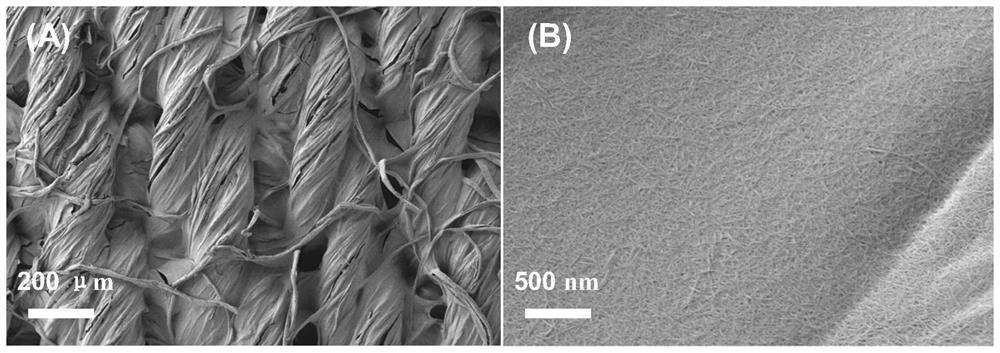

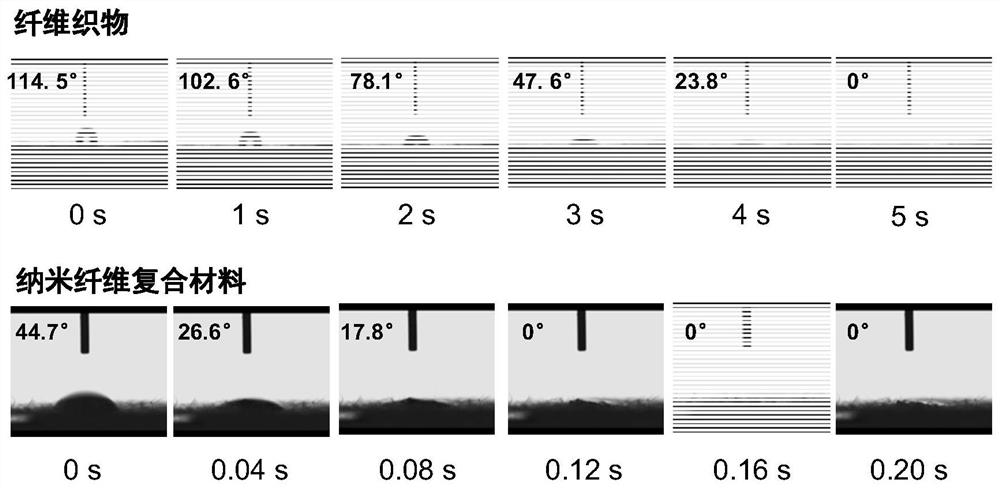

[0079] This example provides a nanocellulose / fiber fabric composite material and its preparation method. This example makes nanofibers with grafted functional groups. It includes the following steps:

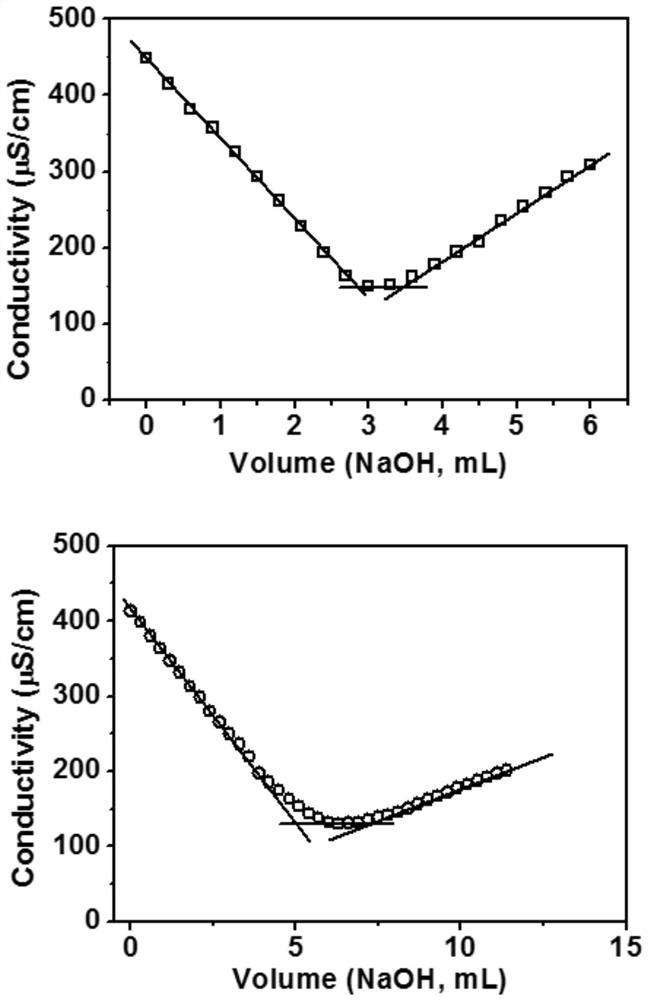

[0080] (1) Preparation of carboxylated nanocellulose. Mix 10 grams of cellulose (bamboo pulp) with 800 milliliters of deionized water, 2 grams of sodium bromide, and 0.4 gram of TEMPO in a 1000 milliliter beaker, stir and dissolve at room temperature. Then add 75 grams of sodium hypochlorite aqueous solution and continue stirring. Sodium hydroxide solution (1M) was added to adjust the pH of the solution to 10.7±0.7, stirred at room temperature for 2-3 days, and finally 80 ml of ethanol was added to terminate the reaction. The reaction mixture was centrifuged and washed. Add deionized water to dilute, then sonicate, and take the supernatant, which is the suspension of carboxylated nanocellulose.

[0081] (2) Preparation of aldehyde-based nanocellulose. Take 8 grams of carbox...

Embodiment 2

[0085] Compared with Example 1, the one selected in this example is the commercially available nanocellulose with grafted functional groups of TC-UCN-001 model.

[0086] Composite of nanocellulose and fiber fabric. Take 100mL of commercially available nanocellulose suspension (0.2wt%), soak 15 grams of fiber fabric (selected from cotton cloth) in it for 30 minutes, take it out and dry it at 120°C for 30 minutes to obtain nanocellulose and fiber Fabric composites.

Embodiment 3

[0088] Compared with Example 1, the only difference lies in the composite step of the fiber fabric. In this example, 100 mL of the oxidized nanocellulose suspension (0.5 wt %) in step (1) and step (2) were respectively taken, and 20 grams of fiber fabric (selected from linen cloth) were soaked in it for 30 minutes, and taken out After drying at 80° C. for 120 minutes, a composite material of nanocellulose and fiber fabric can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com