Tendon running-water quenching method and apparatus

A technology of quenching device and steel bundle, which is applied in the direction of quenching device, furnace, heat treatment equipment, etc., can solve the problems of inability to further obtain the performance of steel bars, difficult control and adjustment of process parameters, etc., and achieve the effect of improving the strength and stability of turning threads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

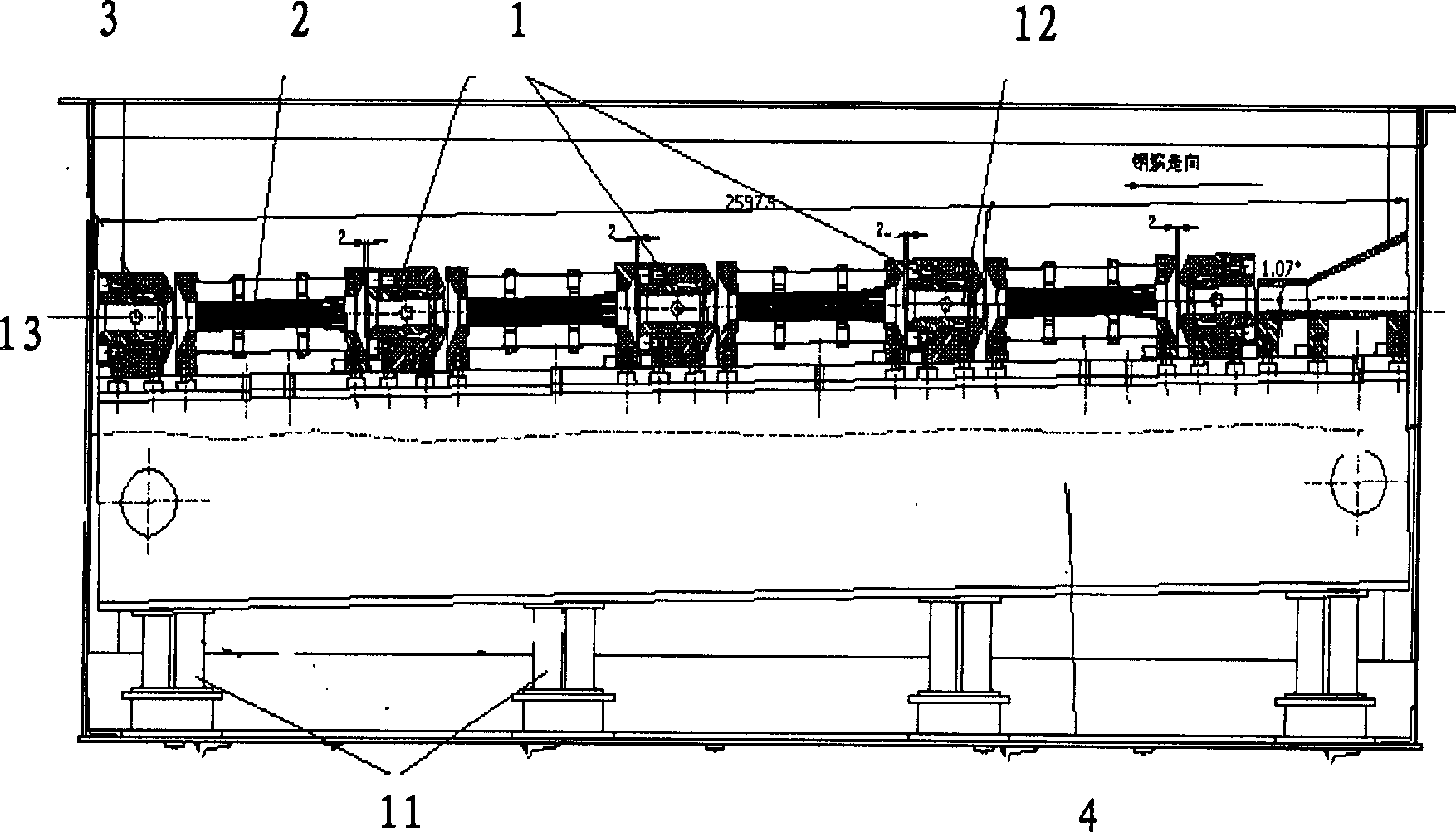

[0046] In this embodiment, beam water quenching is performed on threaded steel bars used in construction and engineering.

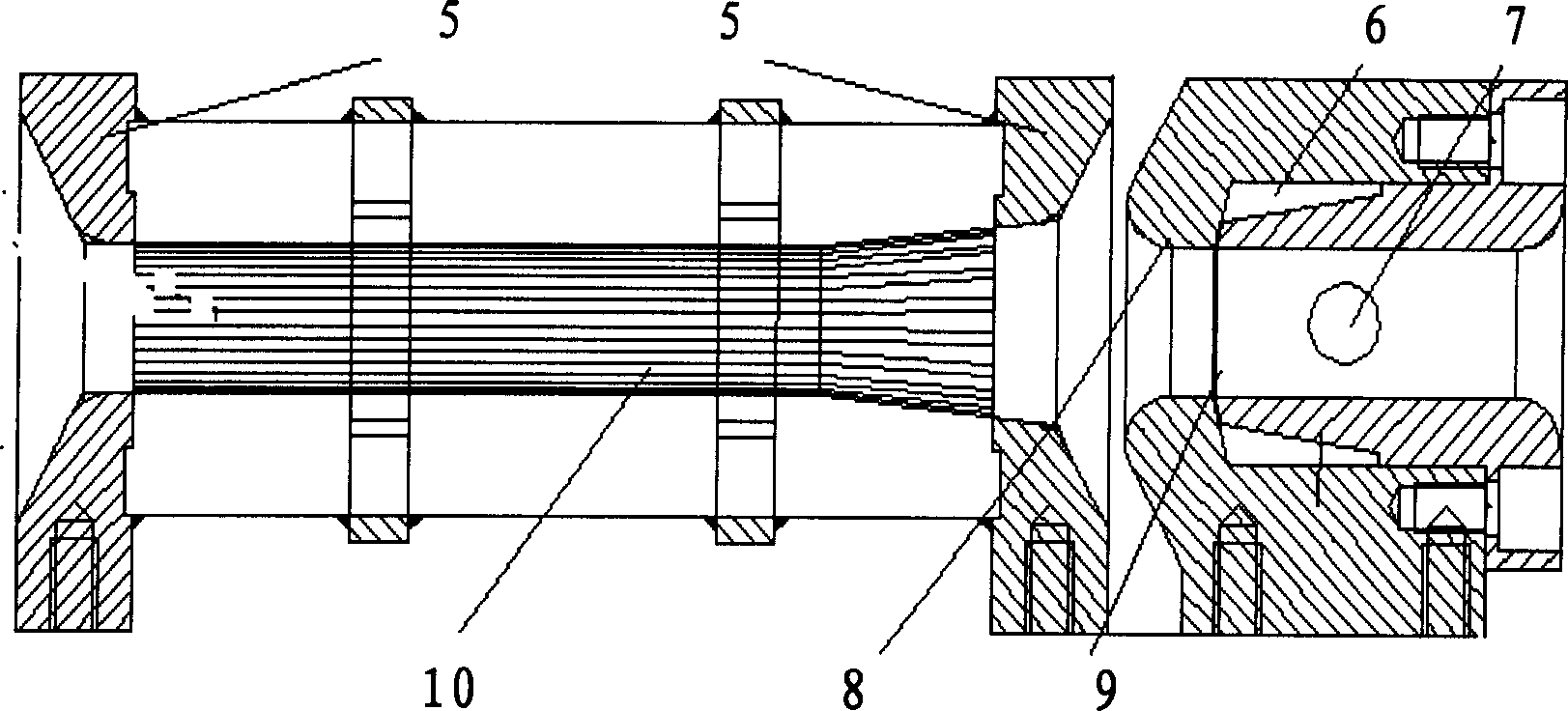

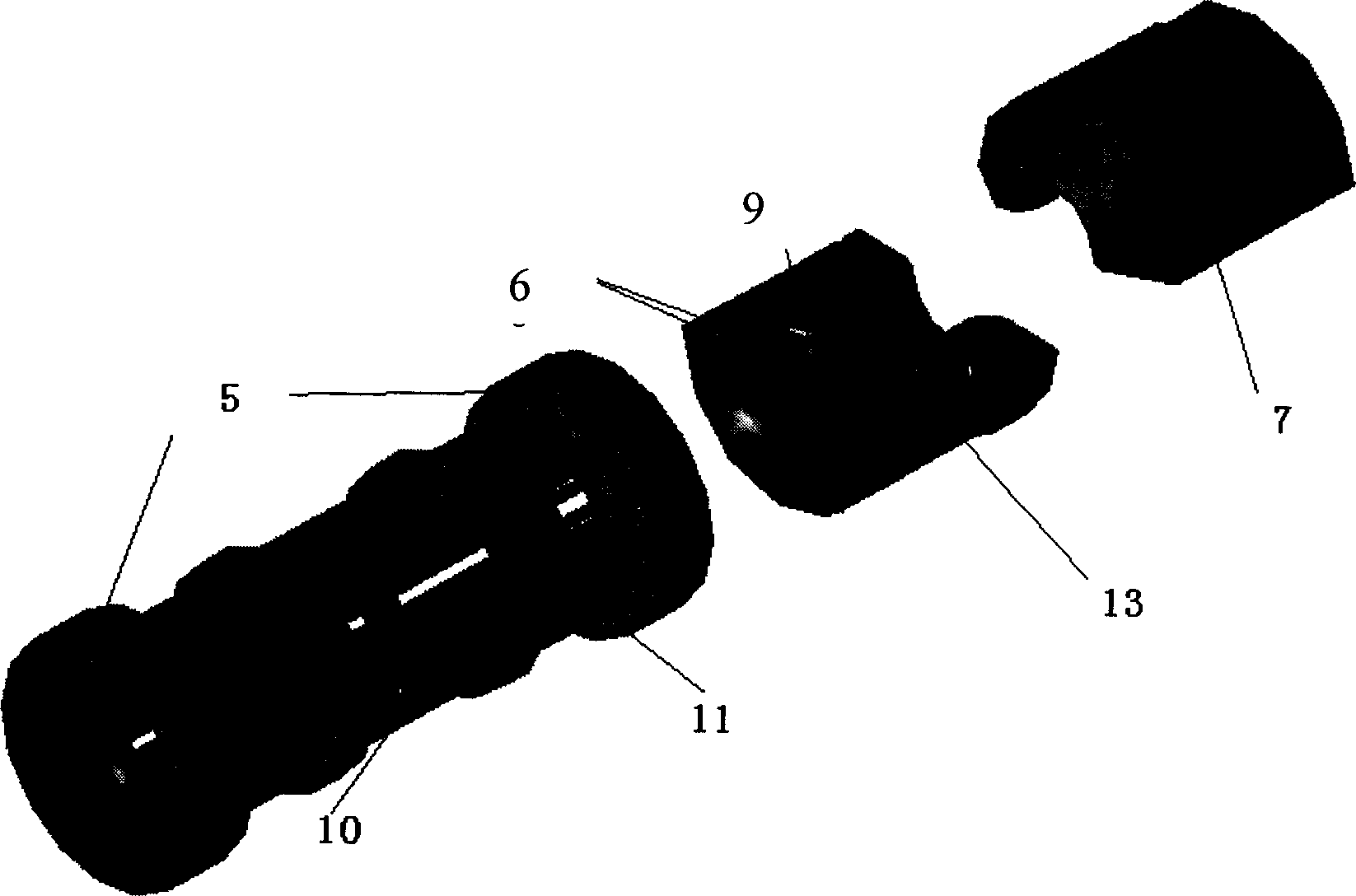

[0047] like figure 1 As shown, in the beam water quenching method and device, 4 beam water quenching section components 1 and 4 squirrel-cage drainage section components 2 constitute a steel beam water quenching channel, such as figure 1 As shown, the threaded steel bar 12 used in construction, engineering, etc. runs from right to left, and enters the first reinforcement beam water quenching section member from the trumpet-shaped port 8 of the beam water quenching section member 1. The component 1 for the quenching section of steel tendons and the multiple squirrel-cage drainage section components 2 are spaced apart from each other. The length of the first beam water quenching section is 0.6-0.8m, the length of the second beam water quenching section is 0.6-0.8m, the third beam water quenching section is 0.4-0.6m, and the fourth beam water quenching sect...

Embodiment 2

[0062] Except that two compressed air nozzles are arranged at the end of the beam flow channel, the water spray holes on the beam water quenching section components are arranged in two rows in an annular shape, and the water spray holes on the beam water quenching section components have an aperture diameter of 3 Except -5mm, other is the same as embodiment 1, constitutes the beam water quenching device of the threaded steel bar that construction, engineering etc. use.

Embodiment 3

[0064] Except that the temperature of the steel bar at which the steel bar starts to enter the first beam water quenching working section is 1200-1400°C, and the passing speed of the steel bar in the beam water quenching channel is 2-6m / s, the others are the same as in embodiment 1, It is a beam water quenching device for threaded steel bars used in construction and engineering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com